Website:

Gas Generation Solutions

Website:

Gas Generation Solutions

Catalog excerpts

NITROGEN GENERATORS electronics Pure Convenience. Nitrogen on demand – anywhere, any time. Flow Rates 10 to 75,000 SCFH Purity Levels 95% to 99.9995% We can custom design any size system to meet your specific needs, schedule or budget. Our generators provide controlled purity and volume, with less cost than bottled gas. Applications: Selective Soldering Wave Soldering Reflow Brazing Inert Atmospheres Nitrogen Atmosphere Benefits: Up to 80% Drose Reduction Support for Lead-Free Alternatives Less Reworks Improved Wetting Improved Yield and Quality Less Voiding Reduced Solder Balls and Icicling Better Thru Hole Penetration Improved Solder Joint Surface Finish Achieve Tighter Keep-Away Distances Increased Process Window Preservation of Soldering Conditions Better Preheating and Flux Activation CONVENIENT SAFE ECONOMICAL RELIABLE FLEXIBLE RAPID ROI BUY, RENT, OR LEASE MADE IN THE USA Represented By:

Open the catalog to page 1

NITROGEN GENERATORS electronics How Does a Nitrogen PSA Work? Nitrogen System Layout Nitrogen Generator N2 Surge Tank Dryer Filter HOW IT WORKS: Compressed air enters one of two sieve beds (filled with carbon molecular sieve-CMS). While the smaller oxygen molecules are adsorbed by the CMS, the larger nitrogen molecules pass through and are stored. Upon saturation, the first sieve bed releases the oxygen, while the second sieve bed starts the process over again. Features and Benefits: C o nv e nie nt: Easy to install and maintain with an unlimited supply of nitrogen. To u c h S cre e n C on...

Open the catalog to page 2

SAMPLE CLIENT LIST Gas Generation Solutions Gas Generation Solutions / Tel: 760-505-1300 / Sales@GasGenerationSolutions.com / www.GasGenerationSolutions.com Alternate Web and Email: sales@mynitrogen.com / www.mynitrogen.com

Open the catalog to page 3

GAS GENERATION SOLUTIONS www.GasGenerationSolutions.com Tel: (760) 505-1300 Fax: (760) 888-1991 Email: twc@gasgenerationsolutions.com Company Name: Contact Name: Tel: Email: Plant Location: Street: City, State, Zip Country: Type of gas required Current supply Operating hours. 8hr, 12, 24 Current / Future Applications: Required Purity. % Pressure at application. PSI Flow Rate: SCFH Peak Flow Rate: SCFH Duration of peak: Hr/min Number of peaks per hr / day Proposed generator location Min / Max operating temp ºF Operating Environment Do you use a gas mixer? COMPRESSOR INFO Compressed...

Open the catalog to page 4All Gas Generation Solutions catalogs and technical brochures

-

Oxygen Insert-GGS

4 Pages

-

Laser Cutting Insert-TWC

3 Pages

-

Food Industry Insert-GasGen

4 Pages

-

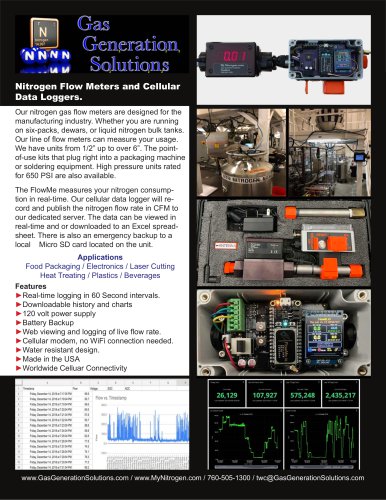

FlowMe-FlowMeters-POU

1 Pages

-

FlowMe-Dataloggers-SMT

1 Pages