Catalog excerpts

THE NAMETRE VISCOLINER > 500 / 800 SENSORS MEASURE VISCOSITY DIRECTLY IN THE PROCESS. The Viscoliner > ή sensors are welded to a base andhermetically sealed from the process. The ViscoLiner > sensors can be mounted in any position into a reactor, tank or pipe. This way the measurement can be done exactly at the place where it is most effective for the userto control their process.The sensor resonates torsionally and its oscillation isservo-controlled at a constant amplitude. A change in viscosity of the materialsurrounding the probe results in a change in the amount of electrical power required to maintain the constant amplitude. This change in power is a mathematical function of the materialΒs viscosity. Constant mechanical amplitude provides superior precision of measurement.The instrument is factory calibrated with Newtonian fluidsand because there is no wear and tear from the instrument itself, recalibration is not necessary. Further a second instrument will provide the exact same results as the first one. Cost of ownership is reduced to a minimum. ViscoLiner > Viscoliner 800 ή 500 Various sensor geometries provide an overall range of 0.1 to 100,000 cP / mPa.s. Even under harsh conditions like temperatures up to 250F / 120аC and pressures up to 300 psig / 20 bar, the ViscoLiner > 500 proves to be areliable instrument. ViscoLiner > ή 800 Various sensor geometries provide an overall range of 0.1 to 1,000,000 cP / mPa.s. Even under harsh conditions like temperatures up to 850F / 450аC and pressures up to 5,000 psig / 350 bar the ViscoLiner > Viscoliner 500 ή 800 proves to be areliable instrument.In all Viscoliner > sensors, flow variations as generated by a tank stirrer or agitatorand pipeline flow does not influence the measurement. The measurement is also impervious to entrained air or sparged nitrogen. A PT100 RTD is integrated into the sensors to provide temperature measurement at the same location as the viscositymeasurement. Zener barriers can be used to make the instruments suitable for installation in hazardous areas.Reproducibility of the viscosity measurement in process is guaranteed at 1% butcustomers have achieved values better than 0.5%. Confidence into your process parameters is assured. >

Open the catalog to page 1

Cylinder LVCylinder MVSphere HVRod XV > (VL800 Only) Sensor dimensions: > = 1.5ؔ/38mm = 1.5ؔ/38mm = 1.25ؔ/32mm = 0.45ؔ/11mmL = 6.5/165mmL = 5.5Ԕ/140mmL = 5.0/127mmL = 5.0Ԕ/127mm Viscosity range: > 0.1 : 1,0001 : 10,00010 : 100,0001,000 : 1,000,000 cP x g/cm3 > Calibration range: > up to 3 continuous decadesup to 5 continuous decades depending on electronics Sensor material/protection: > 316L SS (1.4571) / NEMA 4X316L SS (1.4571) / NEMA 4X Process temperature range: > 32F/0аC to +250F/120аC-40F/-40аC to +570F/+300аC 1 (270F/130аC for max. 30 min.)(Std with air cooling) Block temperature...

Open the catalog to page 2All Galvanic Applied Sciences Inc. catalogs and technical brochures

-

AccuColor

1 Pages

-

Nametre

1 Pages

-

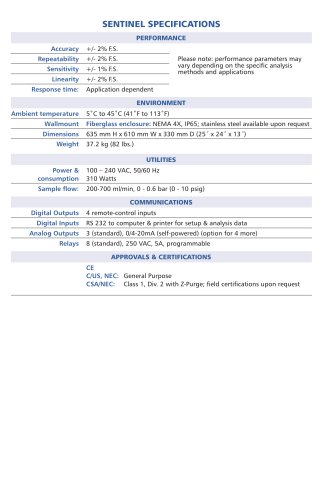

Sentinel

1 Pages

-

MonitekUltraSonic

1 Pages

-

MONITEK

2 Pages

-

SULFURCHROME SPECIFICATIONS

1 Pages

-

FPA 4100™ SPECIFICATION

1 Pages

-

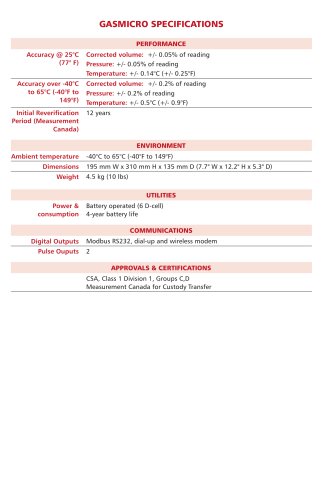

GASMICRO SPECIFICATIONS

1 Pages

-

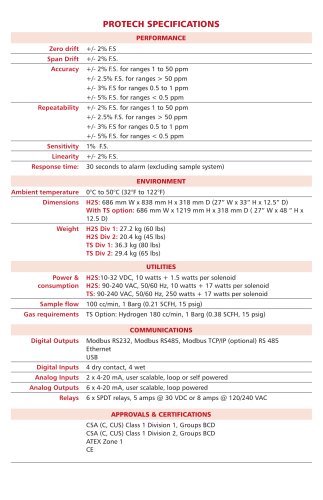

PROTECH SPECIFICATIONS

1 Pages

-

ACCUCHROME SPECIFICATIONS

1 Pages

Archived catalogs

-

961 AG

4 Pages

-

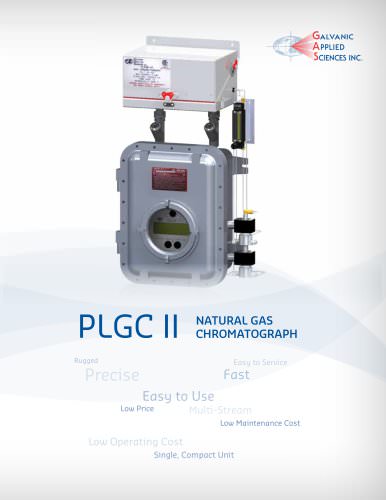

PLGC II Gas Chromatograph

3 Pages

-

Product Showcase

1 Pages

-

903W Natural gas analyzer

3 Pages

-

941 H2S in Liquid Sulfur

1 Pages

-

the 842 Sulfur Gas Chromatograph

8 Pages

-

the Tytronics Sentinel

4 Pages