Website:

Galbiati Group S.r.l.

Website:

Galbiati Group S.r.l.

Group: Galbiati Group

Catalog excerpts

Gear Reducers

Open the catalog to page 1

GEAR REDUCERS Gear reducers and increasers, mechanical power transmissions for mid- and large- sized industrial applications, DESIGN, CONSTRUCTION, AND RECONDITIONING Galbiati Group has extensive experience in the design manufacturing and revamping of mechanical transmissions: □ Steel industry (hot and cold rolling mill) □ Large Edger drives □ Pinion stands and twin drives for mill stands □ Main drives for shears □ Tilting converters drives □ Turbine and pump gearboxes for hydroelectric power plants □ Planetary drives for antenna actuation and for TBM rotating heads □ Drives for rubber and...

Open the catalog to page 3

INSPECTION AND CERTIFICATION Inspection and Certification All Galbiati Group gear drives are “full speed – no load” tested for a minimum of six hours. The gear drive performance (lubrication system, temperature probes, etc.) and its accessories (ejectors, hold down rolls, etc.) are properly checked. On each new unit, as well as on the overhauled one, temperatures (oil, housing, and bearings), noise levels, and vibrations are measured and recorded on relevant test record. A “Certification File” is issued for each drive, which contains the raw materials and all the manufacturing process...

Open the catalog to page 4

□ GEAR DRIVES AND GEARS FOR CEMENT AND SOLID MILLING INDUSTRY Cement Mill Drives □ RUBBER INDUSTRY DRIVES Rubber mixer drive 2500 kw at 77 rpm

Open the catalog to page 5

PLANETARY DRIVES Planetary drives for “TBM” rotating head Planetary drives for antenna actuation

Open the catalog to page 6

DRIVES FOR CABLE CAR SYSTEMS AND HOISTING WINCHES Winch drive installed on the panoramic elevator, “Bigo”, in Genoa Submarine-cable laying winches drum. Specifically manufactured with low temperature – high resistance carbon steel

Open the catalog to page 7

DRIVES FOR METALLURGY INDUSTRY, COLD MILL Cold rolling Pinion Stand Pinion stand for cold mill 5,200 kw – 466 rpm. Roll center distance 450 mm Twin drive for plate cold mill 5,000 kw – 446 rpm. Roll center distance 470 mm Pay-off gear unit sliding on bronze guides, including mandrel and hold down roll. 2,200 mm max. diameter, 1,500 mm, 30,000 kg coil weight Coiler unit including mandrel and coil ejector plate. Motor power 1600 kw – Output shaft 95 rpm (18.5 tons total weight)

Open the catalog to page 8

DRIVES FOR METALLURGY INDUSTRY/HOT MILL Pinion Stand Mill Drive/Twin Drive – Hot Rolling Integrated pinion stand mill drive for special alloys Integrated pinion stand mill drive for continuous cast aluminum rolling mill hot three-stand Tandem Twin Drive for hot aluminum mill Twin drive reversible hot mill

Open the catalog to page 9

EDGER DRIVES Edger drive Vertical twin motor self-supported solution Gears made with Ni/Cr/MO ring gears, on electrowelded frames F1 hot rolling mill pinion stand, 4300 mm sheet width

Open the catalog to page 10

□ STEEL INDUSTRY DRIVES/CONVERTERS Gear Reducers Tilting converter drives/Steel Industry (350 ton) Four motor tilting converter drive unit with during assembly and ntermediate geometrical inspection

Open the catalog to page 11

STEEL INDUSTRY / MISCELLANEOUS APPLICATIONS Steel Pipe Drawer Drive Screw Down drives Steel pipe drawer drive including chain driving pinion, 220 kw – 2 rpm – 150 ton thrust (weight 63,000 kg) Worm screw gear set for screw down drive Shear Drives 1.600 kW crop shear drive at 27 rpm, max 6.000 kNm torque. Total unit weight exceeds 160 ton Double helical output gear for Crop Shear Drive

Open the catalog to page 12

GEAR INCREASERS Hydroelectric power plant gear increaser. Equipped with temperature probes for oil and bearing temperatures detection, and vibration probes with relevant analysis and control equipment GEARBOX RECONDITIONING Galbiati Group reconditions gear drives for all heavy industrial applications Reconditioning Integrated pinion stand drive for wire rolling mill (before and after reconditioning)

Open the catalog to page 13

Bull Gear for 350 ton Steel Converter Drive Crane rotation toothed gears Teeth contact inspection Gear toothed segments for parabolic antenna and radiotelescope application

Open the catalog to page 14

Galbiati Group - Engineering & Machining 23848 Oggiono (LC) Via Cà Bianca Pascolo, 26 Italy | Tel +39 341 2633260 Gear Reducer Division: gear_reducers@galbiatigroup.it http://galbiatigroup.it/riduttori/gear-reducers

Open the catalog to page 16All Galbiati Group S.r.l. catalogs and technical brochures

-

Coil Processing Lines

15 Pages

-

ZEISS MMZ-G 30 60 25

12 Pages

-

Pressa EP4

6 Pages

-

Ultrasonic Test Certificate

1 Pages

-

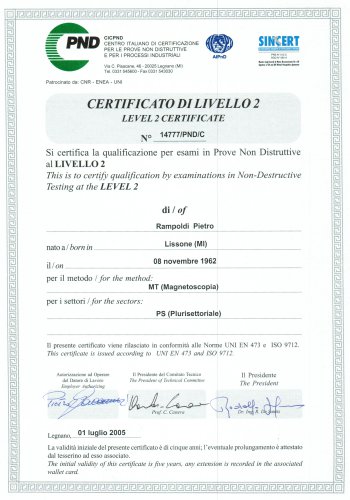

Quality Certificate

1 Pages

-

Galbiati Group

28 Pages

-

Presses for Blanking Laminations

12 Pages

-

Custom Built Machines

12 Pages