Website:

Fusion Incorporated

Website:

Fusion Incorporated

Catalog excerpts

Paste Brazing Soldering & Soldering Alloys A l l oys

Open the catalog to page 1

Table of Contents Filler Metal Introduction The Fusion Paste Process Selecting a Brazing or Soldering Flux Selecting a Brazing or Soldering Filler Metal 2-3 4 5 Fusion Paste Soldering Selection Guide: Paste Solder Fluxes Selection Guide: Paste Solder Filler Metals 6-7 8-9 Fusion Paste Brazing Selection Guide: Paste Brazing Fluxes Selection Guide: Silver Brazing Filler Metals Copper Phos (BCuP) & Copper Zinc Filler Metals Fusion Brazing Filler Metals for Furnace Applications Furnace Brazing Steel with Fusion Paste Alloys 10-11 12 13 14 15 Joining Aluminum With The Fusion Paste Process...

Open the catalog to page 2

The Fusion Pa s t e P ro c e s s Applicators Paste Alloys Custom blended to meet your requirements, each Fusion Paste Brazing or Soldering Alloy contains the following basic components: • Finely atomized filler metal, alloyed to exacting standards for composition, melting range, and compatibility with base metals to be joined. In general, Fusion alloys conform to all accepted industry standards. • Fluxing agent, designed to remove and prevent reformation of surface oxides during heating. Type and amount are carefully matched to the individual application, ensuring consistent, dependable...

Open the catalog to page 3

Selecting a Pa s t e B ra z i ng o r Soldering Flux Base Metals As defined in the Glossary (page 19), a brazing or soldering flux serves to remove and prevent reformation of base metal oxides during heating. Since oxides inhibit effective “wetting” of the assembly with molten filler metal, it is important that an adequate flux be employed during the joining operation. This does not, however, preclude prior cleaning of the assembly (chemical or mechanical) to remove grease, oil, paint, and other impurities. These must be cleaned away to ensure that the flux can act directly on the metal...

Open the catalog to page 4

Selecting a Pa s t e B ra z i ng o r Soldering Filler Metal Base Metals The Fusion Paste Alloy used should contain a filler metal that is able to wet the base metals and be metallurgically compatible with them in order to form a strong bond. Base Metal/Filler Metal Interaction The degree of metallurgical interaction at the grain boundaries is a direct function of time at melting temperature. Depending upon the specific application, a high degree of metallurgical interaction between base metal and filler metal may be either desirable or undesirable. Therefore, the degree of interaction...

Open the catalog to page 5

SELECTION GUIDE Fusion Paste Solder Fluxes Non-Corrosive Fluxes Intermediate Fluxes Fluxes are classified as “Non-Corrosive” when their residue after soldering will not corrode and eventually destroy the joint if allowed to remain. Generally incorporating a rosin base, these fluxes contain mild organic acids which are neutral at room temperature but become slightly acidic upon heating. Neutral, rosin fluxes are particularly useful in electrical applications, where their non-conductive, non-corrosive residue may be safely left on the assemblies. These fluxes usually consist of mild organic...

Open the catalog to page 6

Solder paste PWC-430-830 automatically applied to brass assembly. Fusion Paste Solder Fluxes Flux Type Fluxing Range* Suggested to Remove Residue Flow Characteristics Copper Brass** Recommended For Use On Steel Plated Surfaces Stainless Steel Non-Corrosive GPR 300-525°F 149-273°C LPS 300-525°F 149-273°C MBC 300-595°F 149-313°C Mineral Spirits or Chlorinated Hydrocarbon Solvent Mineral Spirits or Chlorinated Hydrocarbon Solvent Mineral Spirits or Chlorinated Hydrocarbon Solvent Fair Spread Yes No LT No Restrictive Yes No LT No Fair Spread Yes No LT No Intermediate WC 300-525°F 149-273°C Hot...

Open the catalog to page 7

SELECTION GUIDE Fusion Paste Solder Filler Metals Tin/Silver Paste By definition (see Glossary page 19), a soldering filler metal has a melting range generally below 840°F and always below that of the base metal to be joined. As shown in the chart on Pastes containing these metals exhibit better strength than the standard tin/lead series. Although slightly higher in cost, they are exceptionally free flowing and offer excellent electrical conductivity. The absence of lead makes these pastes suitable for use in food-handling vessels where lead is prohibited. page 9, Fusion Paste Solder Alloys...

Open the catalog to page 8

SELECTION GUIDE Fusion Paste Brazing Fluxes STL Very active, free-flowing flux, for use on normal ferrous and non-ferrous base metals. Can also be used on such hardto-braze materials as cadmium-oxide and nickel-chrome. Low-temperature, fluoride compound results in excellent shelf life. Fluxes for Paste Brazing Alloys have been formulated to complement automated operations where quick removal of surface oxides at high temperatures is required. Generally, brazing fluxes are highly corrosive, thus their residue after brazing should be removed. Experience has shown that “standard” flux/binders...

Open the catalog to page 10

Silver based filler metal flows at 1205°F throughout joint interface. Fusion Paste Brazing Fluxes Flux Type STL APW STN STK LHK WSK WSP CTT DMX BMW BMA Fluxing Range* 1000-1600°F 538-871°C 1000-1600°F 538-871°C 1000-1700°F 538-927°C 1000-1700°F 538-927°C 1000-1700°F 538-927°C 1000-1700°F 538-927°C Suggested to Remove Residue Acid or Alkaline Cleaner Acid or Alkaline Cleaner Acid or Alkaline Cleaner Acid or Alkaline Cleaner Acid or Alkaline Cleaner Acid or Alkaline Cleaner Silver Base Filler Metals 1000-1700°F 538-927°C Flux-free 1100-1700°F 593-927°C 1600-1900°F 871-1038°C 1600-1900°F...

Open the catalog to page 11

Fusion Copper Phos (BCuP) & Copper Zinc Filler Metals Dispenser gun applies copper/phosphorus paste deposits to tube/header joints. When phosphorus or phosphorus and silver are added (BCuP), the resulting filler metal exhibits “self-fluxing” properties on copper base metals. These BCuP filler metals, however, should not be used on steel or nickel base metals due to the possibilty of Phosphorus Embrittlement - a weakening condition caused by base metal/filler metal interactions. When copper is combined with zinc or tin (RBCuZn), melting temperature - and resistance to corrosion - are lowered...

Open the catalog to page 13All Fusion Incorporated catalogs and technical brochures

-

DISPENSABLE FLUX PRODUCTS

2 Pages

-

No. 545 - Shotgun Assembly

2 Pages

-

Liquid Line Drier Assembly

1 Pages

-

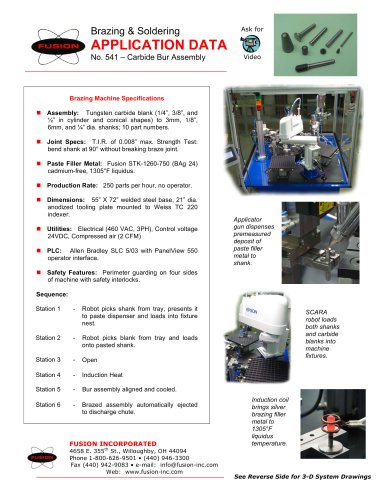

Brazing & Soldering

1 Pages

-

BRAZE MATE Model 200

1 Pages

-

"Braze Mate" Model 150

1 Pages

-

BRAZE MATE Model 100

1 Pages

-

APPLICATION DATA

1 Pages

-

Induction Atmosphere Brazing

2 Pages

-

Carbide Bur Brazing Machine

2 Pages

Archived catalogs

-

Paste Brazing & Soldering Alloys

10 Pages

-

PISTOL GRIP APPLICATOR GUN

1 Pages