Catalog excerpts

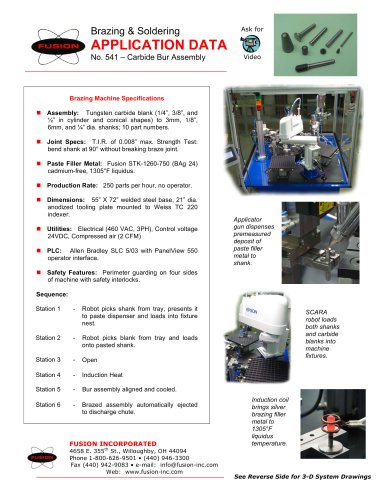

Brazing & Soldering APPLICATION DATA No. 542 – Tubular Heating Elements FUSION INCORPORATED 4658 E. 355th St., Willoughby, OH 44094 Phone 1-800-626-9501 • (440) 946-3300 Fax (440) 942-9083 • e-mail: info@fusion-inc.com Web: www.fusion-inc.com “Braze Mate” Model 100 Machine Specifications .. Assembly: Incoloy tubular heating element to stainless or mild steel flange. .. Paste Filler Metal: Fusion STL-1260-650 (BAg 24), 1305°F/707°C liquidus. .. Production Rate: 30 parts per hour, one operator. .. Dimensions: 36”W x 48”D x 34” load height. .. Utilities: 120V, single phase, 5 Amp, 24VDC; natural gas (48 CFH); 80 psi air (9 CFM); water (1 gallon/minute) and drain. .. PLC: Allen Bradley MicroLogix with AB PanelView operator interface. .. Safety Features: Perimeter guarding on 3 sides of machine with safety interlocks. Sequence: 1. Operator loads heating element and flange into stainless steel fixture. 2. Operator dispenses paste filler metal to joint areas with hand-held applicator gun. 3. Touch switches pressed to actuate automatic brazing cycle. 4. Gas/air burners advance into position, adjust to high flame output, and bring filler metal to brazing temperature. 5. Heat cycle times out, burners retract into low flame condition. 6. Timed air and water cooling. 7. Operator removes brazed assembly and repeats the cycle. Precision heat pattern oscillates, distributing filler metal evenly, creating leakproof joints. Premeasured deposits of silver-based paste filler metal are applied to joint areas.

Open the catalog to page 1All Fusion Incorporated catalogs and technical brochures

-

DISPENSABLE FLUX PRODUCTS

2 Pages

-

No. 545 - Shotgun Assembly

2 Pages

-

Liquid Line Drier Assembly

1 Pages

-

Brazing & Soldering

1 Pages

-

BRAZE MATE Model 200

1 Pages

-

"Braze Mate" Model 150

1 Pages

-

BRAZE MATE Model 100

1 Pages

-

APPLICATION DATA

1 Pages

-

Paste Brazing & Soldering Alloys

20 Pages

-

Induction Atmosphere Brazing

2 Pages

-

Carbide Bur Brazing Machine

2 Pages

Archived catalogs

-

Paste Brazing & Soldering Alloys

10 Pages

-

PISTOL GRIP APPLICATOR GUN

1 Pages