Website:

Fusion Incorporated

Website:

Fusion Incorporated

Catalog excerpts

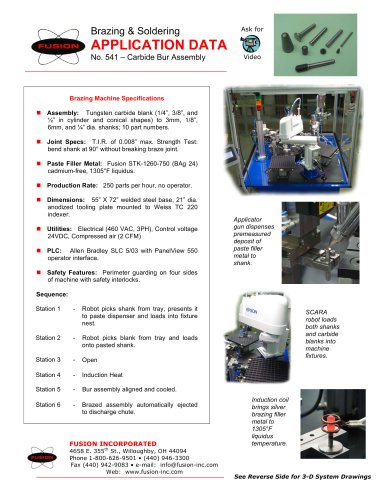

Brazing & Soldering APPLICATION DATA No. 516 - EGR (Exhaust Gas Recovery) Assembly Automatic Paste Application SystemSpecifications ! ! ! ! ! ! ! Assembly: Stainless steel tube bundle and two headers. Paste Filler Metal: Fusion CNT-4777-870, nickel-bearing (BNi2) 1830°F liquidus. Production Rate: 120 assemblies per hour, one operator. Dimensions: 64" x 48" welded steel base, 33" load height. Utilities: Electrical 220 VAC, 1 Phase, 50 Hz, Built to CE specifications. PLC: Allen Bradley SLC 500 with DTAM access panel. Safety Features: Sliding Lexan ® guards on 3 sides of machine with interlock switches; light curtain for E-Stop function. 1. Load top header into fixture under (left side) FE71 Applicator Gun#1. 2. Load bottom header into fixture under (right 3. 4. 5. 6. ! side) FE-71 Applicator Gun #2. Load tube bundle into fixture under (center) robot-controlled, FE-71 Applicator Gun. Operator presses palm buttons; complete rings of paste applied to inner lip of each header, and paste pattern applied to tube bundle. Remove striped headers, invert tube bundle, and same paste pattern applied to opposite end of tube bundle. Tube bundle removed, assembled with headers, and load into separate vacuum brazing furnace. Robot applies Fusion nickel paste accurately around the 37 tube bundle. Robot: Paste pattern is programmable for future product design changes. With hand-held teach pendant, robot is capable of storing up to 99 different programs. FUSION INCORPORATED 4658 E. 355th St., Willoughby, OH 44094 Phone 1-800-626-9501 o (440) 946-3300 Fax (440) 942-9083 o e-mail: sales@fusion

Open the catalog to page 1All Fusion Incorporated catalogs and technical brochures

-

DISPENSABLE FLUX PRODUCTS

2 Pages

-

No. 545 - Shotgun Assembly

2 Pages

-

Liquid Line Drier Assembly

1 Pages

-

Brazing & Soldering

1 Pages

-

BRAZE MATE Model 200

1 Pages

-

"Braze Mate" Model 150

1 Pages

-

BRAZE MATE Model 100

1 Pages

-

APPLICATION DATA

1 Pages

-

Paste Brazing & Soldering Alloys

20 Pages

-

Induction Atmosphere Brazing

2 Pages

-

Carbide Bur Brazing Machine

2 Pages

Archived catalogs

-

Paste Brazing & Soldering Alloys

10 Pages

-

PISTOL GRIP APPLICATOR GUN

1 Pages