Catalog excerpts

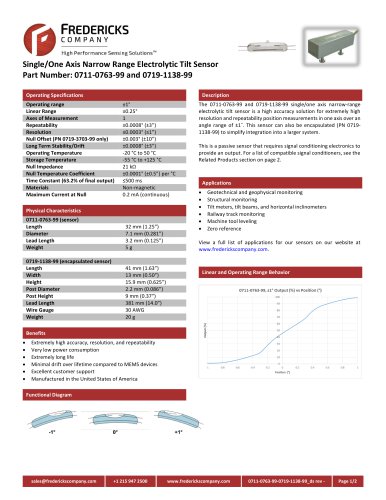

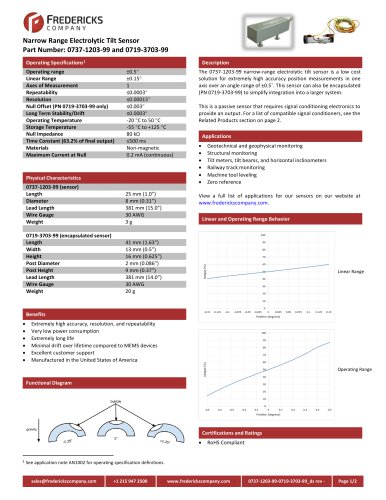

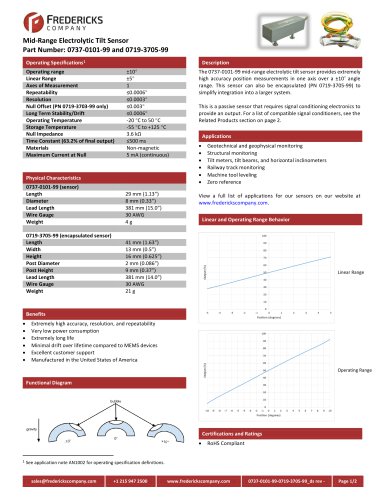

it| Fredericks ^ COMPANY Mid-Range Electrolytic Tilt Sensor Part Number: 0737-0101-99 and 0719-3705-99 Axes of Measurement Repeatability Resolution Null Offset (PN 0719-3703-99 only) Long Term Stability/Drift Operating Temperature Storage Temperature Null Impedance Time Constant (63.2% of final output) Materials Maximum Current at Null Diameter Lead Length Wire Gauge Weight The 0737-0101-99 mid-range electrolytic tilt sensor provides extremely high accuracy position measurements in one axis over a ±10° angle range. This sensor can also be encapsulated (PN 0719-3705-99) to simplify integration into a larger system. This is a passive sensor that requires signal conditioning electronics to provide an output. For a list of compatible signal conditioners, see the Related Products section on page 2. • Geotechnical and geophysical monitoring • Structural monitoring • Tilt meters, tilt beams, and horizontal inclinometers • Railway track monitoring • Machine tool leveling • Zero reference View a full list of applications for our sensors on our website at www.frederickscompany.com. 0719-3705-99 (encapsulated sensor) Length Width Height Post Diameter Post Height Lead Length Wire Gauge Linear Range Benefits Position (degrees) • Extremely high accuracy, resolution, and repeatability • Very low power consumption • Extremely long life • Minimal drift over lifetime compared to MEMS devices • Excellent customer support • Manufactured in the United States of America Operating Range Position (degrees) Certifications and Ratings • RoHS Compliant

Open the catalog to page 1

Dimensional Drawings it| Fredericks ^ COMPANY Mid-Range Glass Electrolytic Tilt Sensor Part Number: 0737-0101-99 and 0719-3705-99 When using an excitation circuit not designed by The Fredericks Company, ensure that no direct current passes through the sensor. Direct current will lead to sensor damage, output drift, and general instability. For a description of hardware and software design for this sensor, see application note AN1000. The 0737-0101-99 and 0719-3705-99 must be mounted horizontally (parallel to the surface of the earth and perpendicular to the force of gravity). For best...

Open the catalog to page 2All The Fredericks Company catalogs and technical brochures

-

Televac br5003

6 Pages

-

Televac MP7FR Cold Cathode

2 Pages

-

Televac MX4A Convection

2 Pages

Archived catalogs

-

0711-0768-99-0719-1143-99_ds

2 Pages

-

Single Axis Narrow Angle

1 Pages

-

2 A Thermocouple Sensor

2 Pages

-

Glass Mid-Range 0715-4101-99

1 Pages

-

Glass Mid-Range 0714-5701-99

1 Pages

-

Glass Mid-Range 0737-0101-99

1 Pages

-

0703-0703-99 TrueTilt

2 Pages

-

Electrolytictilt

4 Pages