Website:

Framo Morat

Website:

Framo Morat

Catalog excerpts

Worm gear sets Catalogue worm gear sets and customised worm gear sets Advanced production methods combined with years of experience in manufacturing gears and providing customers with sound advice have made Framo Morat’s worm gear sets a byword for quality. In recent decades Framo Morat worm gear sets have won appreciable market shares both in Germany and abroad. Besides our catalogue worm gear sets (made to the Framo Morat standard), which we keep in stock in moderate quantities, we also manufacture customised worm gear sets in compliance with customer specifications. Our catalogue worm gear sets are generally available in a wide range of centre distances and transmission ratios directly from stock. Our factory can calculate and manufacture centre distances and transmission ratios deviating from the Framo Morat standard, although it will not always be possible to use available gear cutting tools. The worm gear sets are usually right-handed but can be produced left-handed on request. Depending on the transmission ratio, tooling will have to be procured first. Pressure Angle Due to the manufacturing process, the teeth have a K flank shape. The pressure angle is generally 15° and therefore deviates from the DIN standard of 20°. A pressure angle of 15° allows more favourable radial force component conditions. This reduces the bending stress of the worm shaft and the pushing away of the associated worm gear, reducing the noise and increasing the service life. The efficiency differences due to the modification of the pressure angle are negligible. Metric conversion table Our standard worm gear sets are primarily designed in metric scales. The catalog data can be converted into 'English measures' by using the following conversion table: Metric units Torque (Nm) Distance (mm) English units in.lb. in. ISO-tolerances The worm gear drawings show ISO-tolerances like Ø32H7. If you are not familiar with ISO-tolerances please call Framo Morat or the local distributor to get the precise dimensions. Construction materials The worms are made of case hardened steel with ground bore and worm profile. The worm gears are made of a special alloy (copper-zinc alloy with additives of aluminum, silicon and manganese). Chemically this alloy belongs to the material group of CuZn40Al2 DIN 17660 (new according to EN: CuZn37Mn3Al2PbSi-S40) but is treated for better sliding characteristics. The chemical resistance is very high due to aluminum additives. Mechanical characteristics: • High corrosion resistance • High mechanical strength: Tensile strength Rm: Strain limit RP0,2: Strain at failure A5: Hardness HB2,5/62,5: Shearing strength: Alternating stress: • Good gliding characteristics • High wear resistance Plastic worm gears Plastic worm gears are suitable for low sliding speeds (< 1.5 m/s) and medium tooth pressure due to their bad thermal conductivity. Worms have to be hardened and ground. Plastic worm gears are suitable for 50% torque of bronze worm gears. POM Tensile strength Rm with 23°C: Tensile strength Rm with 70°C: Temperature range: Subject to technical changes Framo Morat GmbH & Co. KG Franz-Morat-Straße 6 • D-79871 Eisenbach www.framo-morat.com info@framo-morat.com

Open the catalog to page 1

Worm gear sets The thermal expansion coefficient is appr. 4 times higher than with bronze. Therefore the backlash shouldn't be too small. At the limit temperature of 100°C the mechanical values drop to 40% of the nominal values. The case temperature shouldn't exceed 50°C, which means the temperature of the gears must not exceed 70°C. Market offers a variety of different bronze for worm gears. Some of them are described here. "Soft" bronze is good for higher speed, "hard" bronze' is good for lower speed. "Soft" bronze worm gears can be paired with unhardened steel worms but that means...

Open the catalog to page 2

Worm gear sets 1. Calculation example (without consideration of the operating conditions) worm gear set A40 U35, lubrication with mineral oil, worm speed 700 min-1, life time 1500 h Question: What's the expected maximum torque? Output torque: =T2 (Mineral oil) x n1 (Factor) x Lh (Factor) = 37,2 Nm x 1,26 x 1,4 = 65,6 Nm Attention! The torque is limited by the tooth strength of the gear. The tooth strength is reached at approx. 300% of the catalog specification for synthetic oil (T2 SO). EXAMPLE: Breaking point for A40 U35 = 46,5 Nm x 3 = 139,5 Nm. Application factors Due to the wide range...

Open the catalog to page 3

Worm gear sets Calculation of the torque (T2 neu) with given life time (Lhneu) Self locking Self-locking is affected by lead angle, surface quality, running speed, lubrication and temperature. A distinction must be made between dynamic (from motion) and static (standstill) self-locking. Dynamic self locking: lead angle up to 3° with grease lubrication; lead angle up to 2,5° with synthetic oil lubrication. Static self locking: lead angle from 3° up to 5° with grease lubrication; lead angle from 2,5° up to 4,5° with synthetic oil lubrication. Lead angles above 4,5° or 5° are not self locking....

Open the catalog to page 4

Worm gear sets Efficiency with driving worm gear The efficiency with driving worm gear is smaller than with driving worm. The following formula can be used: efficiency with driving worm gear efficiency with driving worm (specified in catalog) is negative, self locking is likely. Customer-Specific Worm Gear Sets Customised worm gear sets can be manufactured in compliance with customer specifications in various versions and materials. Framo Morat supplies customised worm gear sets in a centre distance range from 17 to 125 mm, with a max. worm gear diameter of 200 mm. If necessary, Framo Morat...

Open the catalog to page 5

Worm gear sets Subject to technical changes Framo Morat GmbH & Co. KG Franz-Morat-Straße 6 • D-79871 Eisenbach www.framo-morat.com info@framo-morat.com

Open the catalog to page 6

Worm gear sets ME TR IC A17 (17 mm center distance) ground center distance Worm pressure angle 15° MG = mineral grease MO = mineral oil / synthetic grease SO = synthetic oil da1 = tip diameter (worm) z2 = No. of teeth dm2 = pitch diameter (worm gear) dA = max. diameter (worm gear) T2 = output torque i = gear ratio m= lead angle m = module z1 = number of threads dm1 = pitch diameter (worm) * Worm gear set A17U2 only available with polished worm profile and crossed helical gear. ** The hub diameter of the A17U50 worm is 9 mm. All worms and worm gears stocked right hand only. Worm made of...

Open the catalog to page 7All Framo Morat catalogs and technical brochures

-

Compacta

35 Pages

-

Planetary_gears

52 Pages

-

Rotor shafts

4 Pages

-

Modular Linear Systems

4 Pages

-

Commercial training brochure

8 Pages

-

Planetary gears.

52 Pages

-

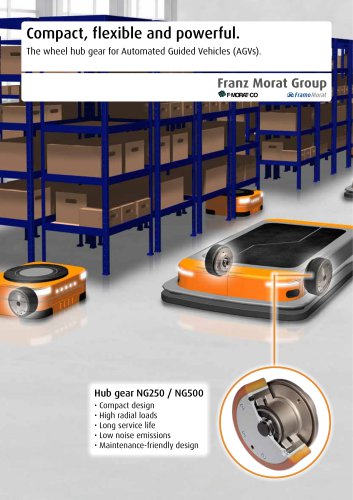

Hub gearbox systems

6 Pages

-

Worm gear sets

30 Pages

-

Framo Morat Image Brochure

8 Pages

-

Drum motor for pool cover

2 Pages

-

Brochure for 100th Anniversary

11 Pages

-

Framo Morat Complete Catalog

76 Pages

-

compact MR6, MS12, MR30, AG160

28 Pages

-

Mounting instructions

28 Pages

-

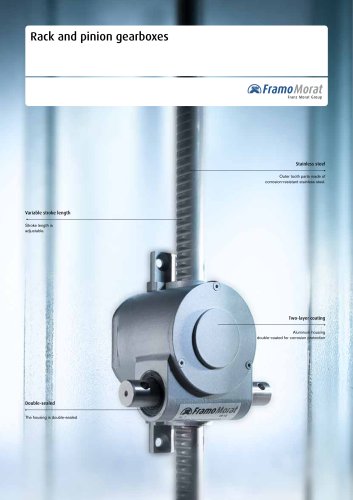

Rack and pinion gearboxes

4 Pages

Archived catalogs

-

Chapter Gear Technology

3 Pages