Website:

Framo Morat

Website:

Framo Morat

Catalog excerpts

Planetary gears. Standard series & custom engineered solutions.

Open the catalog to page 1

- Our motto Customers trust us as their preferred partner for gear and drive engineering. We stand for quality, innovation, efficiency and reliability. Short delivery time The selection of an appropriate planetary gear for your individual application. Contact us by phone or via the inquiry form on www.framo-morat.com Small quantities available on short notice. Delivery time for larger quantities or special requests has to be checked individually CAD drawings Drawings for all series are available on request Flexibility For customized solutions we draw from a large range of single components....

Open the catalog to page 2

Your satisfaction is our ultimate goal. Our services in every aspect of the planetary gear. Framo Morat is not only known for its comprehensive manufacturing expertise. Our customers also revere us as experienced partners in Planetary gears are known for their high efficiency. Owing to the high drive technology. This expertise is the foundation of our planetary gear manufacturing quality of our gearbox series we offer you an excellent price-performance ratio. We place great importance on your flexibility in the configuration and application of our planetary gears. Being faithful to our...

Open the catalog to page 3

Planetary gears • Overview High-End Diameter Gearbox (mm) Nominal output torque (Nm) Emergency stop torque (Nm) Backlash (arcmin) • High load level due • Compact design • Right angle version highest precision, small space to double bearings • High torsional rigidity • Optimum protection against dust particles and water tion due to robotic flange for space restricted applications • High torque level • Highest torsional rigidity • Highest axial loads axial forces permis- entire housing incl. tapered roller output side • Simple mounting without intermediate flange Selection criteria Gearbox...

Open the catalog to page 4

High-End Economy Customer-specific planetary gears ...individually developed for you in accordance with the following parameters: • Gearbox sizes • Gear stages • Gear ratios • Gear types • Bearings • Materials • Lubrication • Interfaces • etc. Custom planetary gears • Low noise level due to ground • Individualized design of material, diameter, bearing, tooth width, helical gearing • High power density • Protection class IP65 etc. on each planetary carrier • Error-free connection to all interfaces • Drive integration into your entire system taking into account the

Open the catalog to page 5

The G-series. Low-backlash planetary gears - compact and highly precise. Bearing system Standard use of maximum preloaded deep groove ball bearings. Optionally, the GSD line is also available with double taper roller bearings to accommodate higher radial and axial forces. For the GSF line the double taper roller bearings are standard. One-piece planetary carrier All planetary carriers are manufactured as a cage made from solid material. This increases quiet operating characteristics while at the same time improving positioning accuracy and reducing backlash. Sun pinion bearing system In the...

Open the catalog to page 6

Full needle bearing Helical cut components All lines have a full needle bearing, which has been especially designed for high torques. All lines are equipped with ground, helical-cut precision components, which ensure low operating noise, very quiet operating characteristics and above-average torque absorption. Slotted hollow input shaft Due to the high surface pressure, the slotted, two-piece hollow input shaft represents the ideal connection between the motor shaft and gearbox. Space-optimized 2 stage design The high-end gearbox lines are constructed in a space-optimized, two-stage design....

Open the catalog to page 7

Planetary gears GSA The easy-to-mount high-end economy gearbox for high power transmissions. The low-backlash planetary gearheads of the GSA series are designed for high positioning accuracy and highly dynamic cycle operation. Ground, helical toothed precision components inside Low backlash for high precision, the gear ensure low running noise and high running smoothness. Thanks to its robust design, the gear unit is convincing in appli- cations in which large radial and axial forces are exerted. The hole High torque level pattern on the output side allows easy mounting. Best corrosion...

Open the catalog to page 8

Planetary gears GSA • High-End range ISO-projection metric Planetary gears GSA • Dimensions A Hole circle diameter output Clamping system diameter Max. motor shaft diameter Housing diameter Centering diameter output Output shaft diameter Shaft height including feather key Hole circle diameter input Shaft length output Shaft length from shoulder Centering depth output Distance from shaft end Max. input length motor shaft Distance to center of screw Distance clamping ring - housing Min. mounting thread x depth Min. mounting thread x depth Min. mounting thread x depth Find more information...

Open the catalog to page 9

Planetary gears GSA • High-End range GSA050 Nominal input speed Standard backlash Torsional rigidity Operating temperature Efficiency Protection class -25°C - +90°C Synthetic grease (lifetime-lubricated) Lubrication Weight with flange* Mounting position Output torques

Open the catalog to page 10

Planetary gears GSA • High-End range Mass moment of inertia *1 Load factor KA=1, n2=100 rpm ,at room temperature T=20°C in new condition *2 Sound pressure level at 1m distance, measured for an input speed of 3000 rpm without load *3 On the center of the output shaft *4 Deviation of up to 10 % possible *5 Service life: 30,000 h, n2=100 rpm *6 Max 1000 cycles per hour. Acceleration torque proportion < 5% of the total operation time *7 Max 1000 cycles over the gear service life *8 Related to the input shaft

Open the catalog to page 11

Planetary gears GSB Low-backlash high-end gears set new standards in torque. Our GSB line stands for high performance in combination with low backlash and high precision. Helical gears ensure a minimum noise level and smooth running. The GSB line aligns economic efficiency with flexibility and is your perfect fit for a multitude of applications. Low backlash for high precision, standard as low as <=3 arcmin, optional as low as <= 1 arcmin High torque level Best corrosion protection also for output side Long product lifetime up to 30,000 h High torsional rigidity Precision ground helical...

Open the catalog to page 12All Framo Morat catalogs and technical brochures

-

Compacta

35 Pages

-

WormGearSets

29 Pages

-

Rotor shafts

4 Pages

-

Modular Linear Systems

4 Pages

-

Commercial training brochure

8 Pages

-

Planetary gears.

52 Pages

-

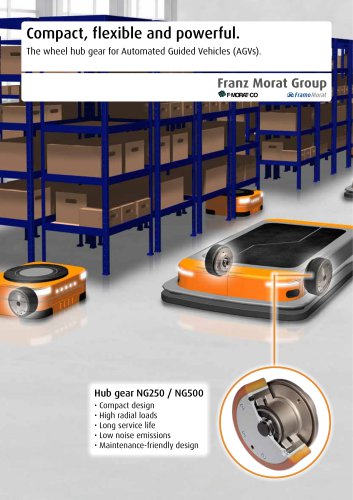

Hub gearbox systems

6 Pages

-

Worm gear sets

30 Pages

-

Framo Morat Image Brochure

8 Pages

-

Drum motor for pool cover

2 Pages

-

Brochure for 100th Anniversary

11 Pages

-

Framo Morat Complete Catalog

76 Pages

-

compact MR6, MS12, MR30, AG160

28 Pages

-

Mounting instructions

28 Pages

-

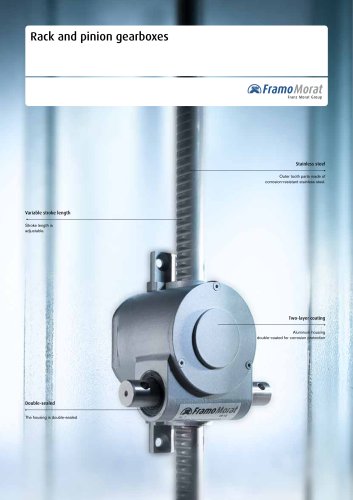

Rack and pinion gearboxes

4 Pages

Archived catalogs

-

Chapter Gear Technology

3 Pages