Website:

Framo Morat

Website:

Framo Morat

Catalog excerpts

Framo Morat is your partner for customized drive solutions. We offer a comprehensive range of gear technology, worm gear sets and drive systems, covering a broad spectrum of applications. We also develop and produce customer- specific drives for numerous applications and sectors. Worm gear sets Page 14 Compacta slip-on geared motors Page 34 Mini linear actuators Page 48 LiMax linear actuators Page 54 Push-pull LinearChains page 60 Planetary gears page 66 Customer-specific drives Page 72 Gear technology Page 10

Open the catalog to page 1

Gear Valley Framo Morat -150 years of industrial culture in the Black Forest Johann Morat founds parent company Development and production of the Development of the company' in Eisenbach company's first series of worm gears first customer-specific drives Founding of Franz Morat The company F. Morat, founded in 1 944, starts processing plastics

Open the catalog to page 2

Made in Gear Valley. We have been deriving motion from energy for over 100 years. Framo Morat is a company with a rich tradition, rooted in specific drive solutions. Whereby we place great value on the industrial culture of the Black Forest. Eisenbach was the typical Black Forest virtues of conscientiousness and already a flourishing center of the watch industry in the rigorousness: Framo Morat is a dependable partner that not 18 century, and many leading producers of precision- only offers advanced technical competence and state-of- engineered parts, precision turned parts and drives are...

Open the catalog to page 3

Core competences

Open the catalog to page 4

Turning things into a knack. Special challenges require special solutions. Whether gear technology, worm gear sets or complete Worm gear sets drives: you will always receive a well thought-out product Having produced over one million worm gear sets annually, from Framo Morat, precisely tailored to your application. Framo Morat is a global market leader. In addition to our In addition to our comprehensive standard range, we design standard series, we also offer customer-specific solutions and produce customer-specific drive solutions according made of steel, bronze, fabric-based laminate or...

Open the catalog to page 5

All work processes from a single source Turning Gear cutting State-of-the-art turning centers with several working spindles, tool magazines and automatic bar feeders ensure maximum performance and economical production of both simple and very complex parts. Grooves, notches, steps, plane surfaces, etc. can be rapidly, accurately and economically produced at several processing centers with automatic material insertion and removal. We can produce straight and helical toothed gear wheels, as well as worms and worm wheels, with our modern gear hobbing machines. Integrated, automatic insertion...

Open the catalog to page 6

Everything under control. Every detail counts. Framo Morat has a very great depth of production: we carry carbonitriding. Precision and quality are our top priorities out work steps such as turning, toothing, cylindrical grind- for production, which is why all processes are designed so ing, profile grinding, hob grinding, gear hobbing and gear that faults are detected and eliminated early on. We ensure shaping ourselves – and can thus guarantee the high qual- reproducible results with maximum quality by means of ity of our products. Our range of performance also includes inline measurement...

Open the catalog to page 7

Gear technology. Customer-specific production.

Open the catalog to page 8

Gear technology Gear technology Gear technology is our specialty: we produce customerspecific gear wheels with internal and external teeth, rotor shafts, pinions and chain sprockets as well as numerous special solutions. Whereby we use a wide range of materi- Gear technology • Individual production according to customer requirements als, depending on the requirements – steel, aluminum, • iameters of up to 300 mm, modules up to size 6, D shaft lengths of up to 480 mm a variety of non-ferrous metals and plastic. We thus guaran- • Straight or helical toothed tee that our customers always...

Open the catalog to page 9

Perfect gear teething. The basis of every good drive. Nothing runs properly without gear wheels: they are the requirements that must be taken into account during fundamental element of every drive. So it is all the more development and production. For example, components in important that these central components are produced with construction machines and industrial trucks must be very maximum quality. This is guaranteed for all products from robust, while those for use in the medical sector principally Framo Morat – so our customers can rely on the depend- have to run quietly. Framo Morat...

Open the catalog to page 10

Gear technology Gear technology Application examples Gear and drum motors Shafts and geared parts of all sorts are used in gear and drum motors for applications in textile machinery or in conveyor systems and hoisting equipment. The drives are extremely robust and durable as a result of high-quality, precisely fitting components from Framo Morat. Automotive Chain and pump wheels from Framo Morat are used in the drive units of major German sports car producers. They must meet maximum demands regarding grinding quality, stability, precision and quiet running. Industrial trucks and electric...

Open the catalog to page 11

Worm gear sets. Standard series and customer-specific designs.

Open the catalog to page 12

Worm gear sets Worm gear sets Our worm gear sets cover a wide range of applications. The more than one million wheel sets produced in-house annually – most of them in customer-specific designs – demonstrate our many years’ experience and high performance capabilities. Our standard wheel sets are produced with diameters of from 20 to 135 mm and center distances of from 17 to 80 mm. We also offer customer-specific wheel sets with Worm gear sets • Individual production according to customer specifications • Diameters of from 20 to 250 mm, center distances of from 17 to 125 mm, Module up to 8,...

Open the catalog to page 13

Tried and tested – in their millions. The right wheel set for every application. The functional principle of worm wheels has remained For producers of gears, motors and drives, worm gear sets unchanged for over 100 years: a screw-shaped worm from Framo Morat are the benchmark for maximum preci- engages a gear wheel, the so-called worm wheel. This sion and reliable, durable operation. Whether in the gears results in the axes being displaced by 90°. Worm wheels of automatic doors and gates, in actuators for aligning are generally used where large gear ratios (of up to parabolic antennae, in...

Open the catalog to page 14All Framo Morat catalogs and technical brochures

-

Compacta

35 Pages

-

Planetary_gears

52 Pages

-

WormGearSets

29 Pages

-

Rotor shafts

4 Pages

-

Modular Linear Systems

4 Pages

-

Commercial training brochure

8 Pages

-

Planetary gears.

52 Pages

-

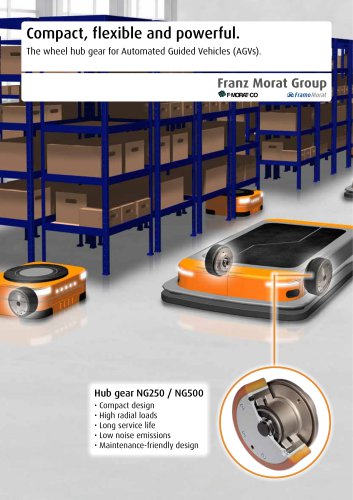

Hub gearbox systems

6 Pages

-

Worm gear sets

30 Pages

-

Framo Morat Image Brochure

8 Pages

-

Drum motor for pool cover

2 Pages

-

Brochure for 100th Anniversary

11 Pages

-

compact MR6, MS12, MR30, AG160

28 Pages

-

Mounting instructions

28 Pages

-

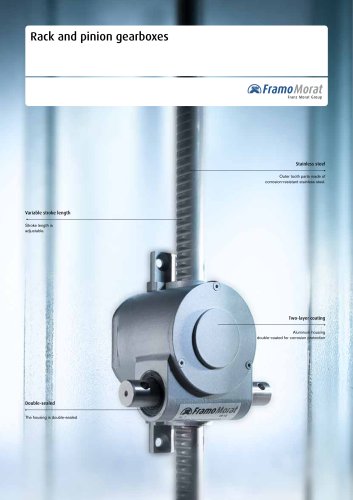

Rack and pinion gearboxes

4 Pages

Archived catalogs

-

Chapter Gear Technology

3 Pages