Website:

Framo Morat

Website:

Framo Morat

Catalog excerpts

[ advancing e-mobility ] [ drive solutions for the mobility of the future ]

Open the catalog to page 1

[ advancing e-mobility ] [ joining forces ] Morat Swoboda Motion is a young, dynamic company that is advancing electromobility through innovative drive solutions. Founded in 2018, the core business of the joint venture between the globally active companies Franz Morat Group and Swoboda, is the development and production of components and systems for all mobile electro-motive applications. Whether gear technology or drive technology, metal processing or plastic injection molding technology, electronics, mechatronics, sensors or actuators – at Morat Swoboda Motion, you get everything from a...

Open the catalog to page 2

[ developing ideas ] [ from specification to serial production ] The high demands placed on the gear components and drive units of the future pose major challenges for the development and production process, which can only be solved with comprehensive expertise. On the way to more efficient gear units, Morat Swoboda Motion uses its knowledge of the material properties of both metals and plastics and their combination. Especially in the early stages, the gear concept and gear design must match the materials used. During the whole process, we closely support you from the creation of the...

Open the catalog to page 3

[ generating motion ] [ drive solutions for the mobility of the future - micromobility ] No other area of mobility places such high demands on gear and drive technology as micromobility. Depending on the requirements profile, there is a conflict of interest between the attributes of installation space, weight, power density, efficiency and noise. Reducing weight by slimming down components, for example, can cause vibration and result in greater noise development. In e-bikes, though, this is precisely what has to be avoided, since a smooth ride is paramount for many customers when making a...

Open the catalog to page 4

[ generating motion ] [ drive solutions for the mobility of the future - automotive ] The automotive industry invests in research and design more than any other industry. The further development of classic drives and alternative fuels, the expansion of electromobility and the digital revolution in cars - from autonomous driving to connectivity - are the driving themes of the future that offer great potential for a new, safe and efficient era of mobility. Battery electric drives, fuel cell electric drives, modern diesel, gasoline or hybrid drives - all concepts offer specific advantages for...

Open the catalog to page 5

[ being present ] [ state of the art production where every detail counts ] At our Morat Swoboda Motion production site in Nowa Ruda, Poland, founded in 2018, we have been producing geared drive components for electromobility on 4,500 m² since June 2019. The new plant houses all quality-critical manufacturing technologies, such as hobbing, vacuum hardening, centerless grinding, hard turning and gear grinding in-house. The automation concept intelligently interlinks the processing machines. The parts are stocked via slidein carts with identical system pallets. In parallel, numerous robots...

Open the catalog to page 6

[ launching careers ] Morat Swoboda Motion is a young, dynamic company that is advancing electromobility through innovative drive solutions. To achieve our ambitious growth targets and strengthen our creative, multicultural team, we are looking for people who want to follow this exciting path with us and take on responsibility. Apply now at https://jobs.morat-swoboda.com Morat Swoboda Motion GmbH Franz-Morat-Straße 6 D-79871 Eisenbach +49 7657 88-0 info@morat-swoboda.com https://www.morat-swoboda.com https://www.linkedin.com/company/morat-swoboda-motion

Open the catalog to page 7All Framo Morat catalogs and technical brochures

-

Compacta

35 Pages

-

Planetary_gears

52 Pages

-

WormGearSets

29 Pages

-

Rotor shafts

4 Pages

-

Modular Linear Systems

4 Pages

-

Commercial training brochure

8 Pages

-

Planetary gears.

52 Pages

-

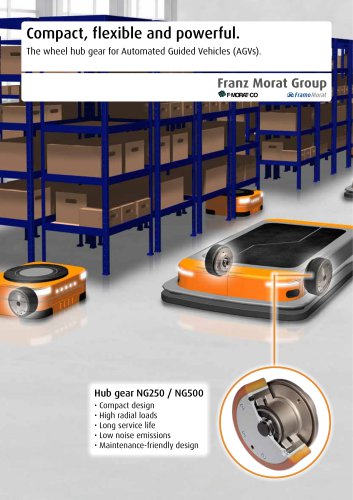

Hub gearbox systems

6 Pages

-

Worm gear sets

30 Pages

-

Framo Morat Image Brochure

8 Pages

-

Drum motor for pool cover

2 Pages

-

Brochure for 100th Anniversary

11 Pages

-

Framo Morat Complete Catalog

76 Pages

-

compact MR6, MS12, MR30, AG160

28 Pages

-

Mounting instructions

28 Pages

-

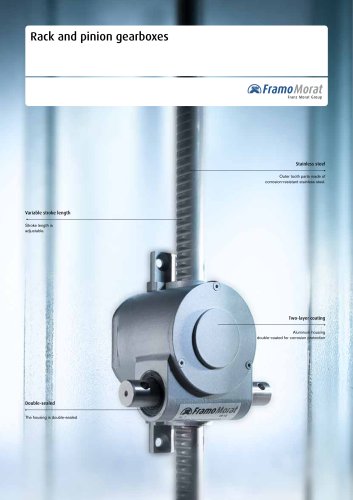

Rack and pinion gearboxes

4 Pages

Archived catalogs

-

Chapter Gear Technology

3 Pages