Website:

FPT Industrial S.p.A.

Website:

FPT Industrial S.p.A.

Group: Iveco Group

Catalog excerpts

ON ROAD FPT INDUSTRIAL S.p.A. Via Puglia 15, 10156 – Torino, Italy marketing1@fptindustrial.com www.fptindustrial.com

Open the catalog to page 1

Whatever you should move, either people or goods, FPT Industrial offers state-of-the-art powertrain solutions for On Road applications. FPT Industrial engines are designed and manufactured for every kind of application from light, medium and heavy commercial vehicles to buses, allowing customers to completely rely on their cutting-edge technological contents and their reduced cost of ownership. The presence of sophisticated electronic injection systems (third generation Common Rail), the choice of many air handling devices (Waste Gate, Variable Geometry and Two Stage Turbocharger) and the...

Open the catalog to page 3

FPT Industrial offers superior technology and outstanding advantages RUNNING COSTS REDUCTION Low fuel consumption Best in class in maintenance intervals Passive DPF regeneration technology No vehicle downtime thanks to no DPF forced/parked regeneration Aftertreatment reliability thanks to more than 3 Millions of aftertreatment produced and more than 25 years of experience on SCR system Power demand and torque response guaranteed in the most severe operating conditions for a wide range of applications State-of-the-art injection systems and turbocharging solutions for improved fuel economy...

Open the catalog to page 4

THE SOLUTION FOR THE FUTURE, TODAY SCR ONLY TECHNOLOGY FOR Euro VI step C Technological excellence and product innovation for FPT Industrial represent the truly determining factor and part of its primary strategic mission. The company is focusing its research and development activities in order to become the innovation leader in the industrial powertrain field and a reference provider of the most cost-efficient powertrain solutions for Euro VI step C. FPT Industrial aims to comply with the new emission limits ensuring a minimal impact on the vehicle architecture and the lowest possible...

Open the catalog to page 7

During the combustion process, inside a Diesel engine, the chemical energy is transformed into a mechanical one. Because of the chemistry of combustion, several toxic substances are produced, of which the most harmful are Nitrogen Oxides (NOX) and Particulate Matter (PM). The new Heavy Duty Euro VI step C exhaust emission regulations, which applied to all new heavy duty commercial vehicles and buses registered from 1st January 2017, introduce significant reductions in the On Board Diagnostic Threshold limits of these harmful pollutants: More severe OBD Thresholds Limits (OTL) for...

Open the catalog to page 10

Published on 13/06/2014 Postponement of Phase B for Diesel engines (integrated on Phase C) O EURO VI B+C Euro VI Step New requirements of Step C vs. EuroVI A Monitoring of DPF allowed instead of the demonstration of OTL limit 25 mg/kWh

Open the catalog to page 13

Euro VI step C engines Based on an already state of the art engine range, Euro VI step C maintains the same base engines hardware of Euro VI step A, allowing our customers to retain their class leading features, such as minimized Total Cost of Ownership. Key to the optimization of combustion efficiency is high mean effective cylinder pressure and high injector nozzle pressures. To achieve these aims, important changes to the crankcase and cylinder head design have already been made in Euro VI step A, resulting in an increase in structural rigidity and in swept volume. The engines fitted...

Open the catalog to page 14

Low operating costs thanks to fluids economy leadership Best in class vehicle uptime due to low engine wear and long maintenance intervals (up to 150.000km, depending on mission) Best in class on specific power and torque Engine and Hi-eSCR aftertreatment system compact and lean design assuring low total weight and easy installation

Open the catalog to page 15

Due to the opposite reaction to combustion temperature, the reduction of either of the combustion products (NOX or PM) necessarily implies the increase of the other one. In order to further reduce NOX, as required by Euro VI step C, it is necessary to work on different combustion management and exhaust gas treatment system. This means that Euro VI step C emission limits can be reached only through the use of SCR (Selective Catalytic Reduction), either with or without EGR. The use of an EGR system reduces the NOX emissions in the combustion chamber, through exhaust gas recirculation with a...

Open the catalog to page 16

“Closed” loop control to allow precise dosing of NOX and ammonia sensors to provide accurate info on the composition of exhaust gases and reduce the use of AdBlue NOX Adaptive AdBlue dosing system in order to cut the level of NOX emissions entering the SCR catalyst Thermally insulated high turbulence mixing, to allow homogeneous hydrolysis of urea, creating correct distribution in exhaust gas flow Improved exhaust gas temperature control to speed up SCR light-off in the cold part of emission cycle All the components of the exhaust after-treatment system are contained in a compact and fully...

Open the catalog to page 17

HI-eSCR main components are: ✓ The Diesel Oxidation Catalyst (DOC) V The Passive Diesel Particulate Filter (DPF) ✓ The AdBlue dosing module ✓ The AdBlue mixer The Selective Catalytic Reduction (SCR) V The Clean Up Catalyst (CUC) The whole system is fitted with a network of integrated sensors to control the NOX and any excess of NH3 (ammonia) emitted. Exhaust gas flow coming from the engine enters the DOC, where NO is oxidised in NO2, which helps to reduce the PM in the subsequent passive DPF. The filter is automatically regenerated at lower temperatures compared to the active DPF used by...

Open the catalog to page 18

Electronic Control Unit Dosing module Diesel Oxidation Catalyst Diesel Particulate Filter PM oxidation with NO2 3 AdBlue ® / DEF INJECTION Hydrolysis NH3+ CO2 4 Selective Catalytic Reduction NO and NO2 reduction by NH3 to N2 and H2O Clean-Up Catalyst Residual NH3 oxidation *AdBlue ® / DEF = CO(NH2)2 + H2O LEGEND PM Particulate Matter HC unburnt Hydrocarbons NOx Nitrogen Oxides CO Carbo

Open the catalog to page 20

Six reasons to choose HI-eSCR 1 FPT Industrial’s heritage in SCR technology is well-established. From the introduction of the Euro IV emission regulations in 2005 we have equipped more than 650.000 vehicles with this technology. OUTSTANDING PERFORMANCE Our engines are developed to maximize torque and power density with the shortest load response time, without compromising the impact on the environment, due to the use of the HI-eSCR system. FUEL CONSUMPTION The efficiency of the combustion process optimizes fuel consumption reducing customer running costs. The absence of EGR improves engine...

Open the catalog to page 21All FPT Industrial S.p.A. catalogs and technical brochures

-

C90 410

6 Pages

-

N67 NG-CONSTRUCTION

1 Pages

-

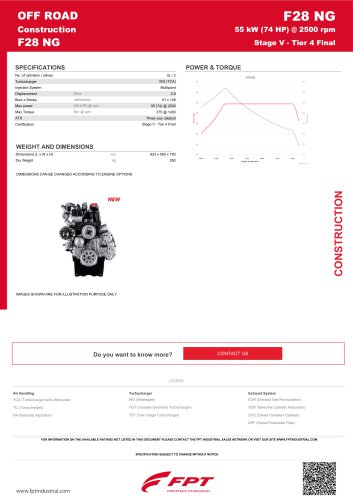

F28 NG-CONSTRUCTION

1 Pages

-

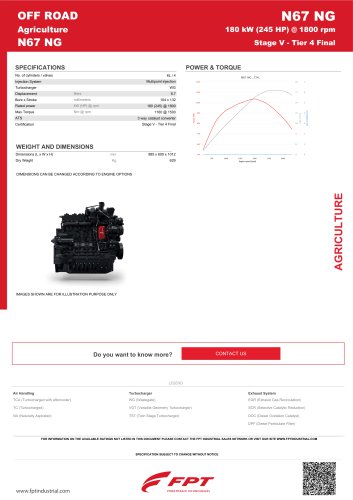

N67 NG-AGRICULTURE

1 Pages

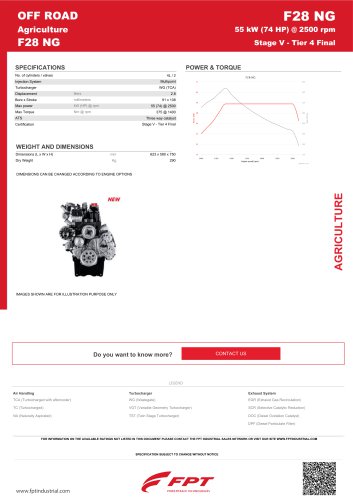

-

F28 NG

1 Pages

-

CURSOR 9 NG-BUSES

1 Pages

-

XCURSOR 13 NG

1 Pages

-

XCursor 13

1 Pages

-

N67 NG-BUSES

1 Pages

-

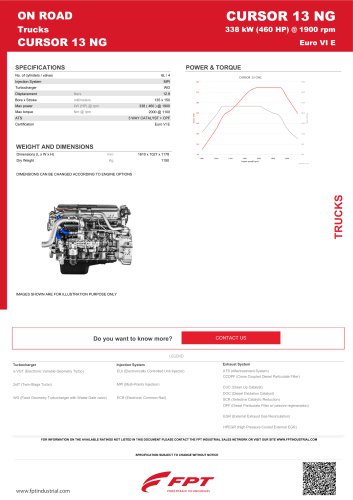

CURSOR 13 NG

1 Pages

-

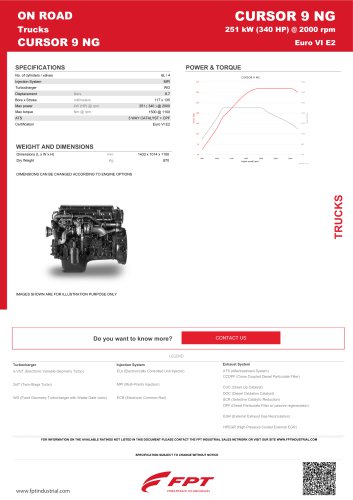

CURSOR 9 NG

1 Pages

-

N67 NG

1 Pages

-

WATER PUMP

6 Pages

-

TURBOCHARGER

6 Pages

-

STARTER MOTOR

6 Pages

-

SHORT BLOCK

6 Pages

-

OIL FILTER

8 Pages

-

LONG BLOCK

6 Pages

-

INJECTOR

8 Pages

-

HIGH PRESSURE PUMP

8 Pages

-

FPT GENUINE CYLINDER HEAD

6 Pages

-

FUEL FILTER

8 Pages

-

ALTERNATOR

10 Pages

-

Brochure MyFPT App

6 Pages

-

Brochure REMOTE ASSISTANCE

13 Pages

-

PROACTIVE ASSISTANCE

7 Pages

-

F1A 85 kW

1 Pages

-

N45

1 Pages

-

F1C NG

1 Pages

-

FPT INDUSTRIAL MARINE COMMERCIAL

27 Pages

-

S8000

1 Pages

-

GENERATOR SETS

20 Pages

-

ON ROAD

51 Pages

-

OFF ROAD CONSTRUCTION

33 Pages

-

MARINE

26 Pages

Archived catalogs

-

OFF ROAD AGRICULTURE 2022

37 Pages

-

OFF ROAD AGRICULTURE 2019

33 Pages

-

POWER GENERATION

70 Pages

-

MARINE

40 Pages

-

OFF ROAD

74 Pages