Website:

FPT Industrial S.p.A.

Website:

FPT Industrial S.p.A.

Group: Iveco Group

Catalog excerpts

OFF ROAD FPT INDUSTRIAL S.p.A. Via Puglia 15, 10156 – Torino, Italy marketing1@fptindustrial.com www.fptindustrial.com

Open the catalog to page 1

Innovation, performance and constant improvement, these are the drivers for our industrial machinery: earthmoving and construction machinery, agriculture, irrigation and special machines. Every type of engine is designed to fulfill the needs of all industrial applications, adopting the most advanced technologies: innovative structure, multi-valve systems, fixed or variable geometry turbochargers, state-of-the-art mechanical injection systems, high pressure Common Rail injection systems and electronically controlled unit injectors. The experience in different application fields, combined...

Open the catalog to page 3

PERFORMANCE Power demand and torque response guaranteed in the most severe operating conditions for a wide range of applications State-of-the-art injection systems and turbocharging solutions for improved fuel economy Proven and breakthrough after-treatment technologies for emissions reduction and low operating costs RESPECT FOR THE ENVIRONMENT Compliance with the most stringent emissions legislations (Tier 4B/Stage IV) thanks to HI-eSCR without DPF RUNNING COSTS REDUCTION Best in class in maintenance intervals Low fuel consumption FLEXIBILITY Availability of a wide range of...

Open the catalog to page 4

THE TIER 4B/STAGE IV SCR ONLY TECHNOLOGY Technological excellence and product innovation for FPT Industrial represent the truly determining factor and part of its primary strategic mission. The company has focused its research and development activities in order to become the innovation leader in the agriculture and construction powertrain field and a reference provider of the most cost efficient powertrain solutions for Tier 4B/Stage IV. FPT Industrial complies with emission legislations ensuring a minimal impact on the vehicle architecture and the lowest possible increase in cost, an...

Open the catalog to page 7

During the combustion process, inside a Diesel engine, the chemical energy is transformed into a mechanical one. Because of the chemistry of combustion, several toxic substances are produced, of which the most harmful are Nitrogen Oxides (NOX) and Particulate Matter (PM). Since 2011, when Tier 4A/Stage IIIB came into force, many efforts have been made to reduce pollutants that are damaging the environment. Tier 4B/Stage IV compliance, introduced in 2014, implied a further significant reduction of NOx (- 80% vs. Tier 4A/Stage IIIB levels), while PM is not affected by further reduction,...

Open the catalog to page 10

EUROPEAN NON ROAD MOBILE MACHINERY, AGRICULTURAL AND FORESTRY TRACTORS & USA NON ROAD COMPRESSION-IGNITION ENGINE EMISSION STANDARDS 130 < P < 560 kW TIER 3 / ST IIIA TIER 4A / ST IIIB TIER 4B / ST IV STAGE V 56 < P < 130 kW TIER 4A / ST IIIA TIER 4B / ST IIIB STAGE V 19 < P < 37 kW After the introduction of Tier4B / StagelV emission limits in 2014-2015, a further regulation re-enforcement is under discussion for European Non-Road applications; new Stage V regulation is expected to be introduced in 2019 or 2020 depending on power levels Emission Durability Period: 8000 hours,...

Open the catalog to page 12

CO Carbon Monoxide HC Hydrocarbons NOx Nitrogen Oxides PM Particulate Matter PN Particle Number 1 NMHC for US Tier Limits 2 US Tier 4A and Tier 4B PM limit is 0.02, but with rounding allowed in US this limit is equivalent to 0.024999... = 0.025 3 3.4 in US 4 Tier 2 for P > 560 kW and P < 19 kW 5 8.0 for P < 8 kW 6 Tier 4A: 0.3; Stage IIIB: 0.025 Emission Durability Period: 8000 hours, 10 years No new type approval in Europe for existing emission stage permitted in the year before new emission stage introduction No emission regulation in Europe for P < 19 kW and P > 560 kW

Open the catalog to page 13

By way of continuous technical advances to an already state of the art engine range, Tier 4B/Stage IV sees also the introduction of reengineered engines, allowing our customers to retain their class leading features, such as minimized total cost of ownership and outstanding performance. Key to the optimization of combustion efficiency is high cylinder pressure and high injector nozzle pressures: engines adopting the latest generation of Common Rail system feature peak nozzle pressures of up to 2200 bar. To achieve these targets, crankcase and cylinder head design has been improved to ensure...

Open the catalog to page 14

V Increase vehicle productivity thanks to better transient response >/ No additional turbocharger's complexity while ensuring outstanding performance ✓ Low operating costs thanks to high combustion efficiency and long service intervals (up to 600h, depending on the mission) y/ Engine lean design and state-of-the-art HI-eSCR after-treatment system, flexible and easy-to-install >/ Lean technology improving durability and reliability V No additional cooling requirements on both radiator dimensions or fan drive

Open the catalog to page 15

HI-eSCR system Due to the opposite reaction to combustion temperature, the reduction of either of the combustion products (NOX or PM) necessarily implies the increase of the other one. In order to further reduce NOX, as required by Tier 4B/Stage IV, it is necessary to work both on combustion management and exhaust gas treatment system. This means that Tier 4B/Stage IV emission limits can be reached only through the use of SCR (Selective Catalytic Reduction), either with or without EGR. The use of an EGR system reduces the NOX emissions in the combustion chamber, lowering combustion...

Open the catalog to page 16

0 "Closed" loop control through NOx and Ammonia All after-treatment components are packaged in a sensors to provide accurate monitoring of exhaust compact and fuHy enc|osed pr°viding flexib|e gas composition; adaptive dosing system to reduce layout options to simplify installation on machines. AdBlue Thermally insulated high turbulence mixer, to allow homogeneous hydrolysis of urea, ensuring correct distribution in exhaust gas flow Improved exhaust gas temperature control to speed up SCR light-off in the cold part of emission cycle through an electronically-controlled exhaust flap

Open the catalog to page 17All FPT Industrial S.p.A. catalogs and technical brochures

-

C90 410

6 Pages

-

N67 NG-CONSTRUCTION

1 Pages

-

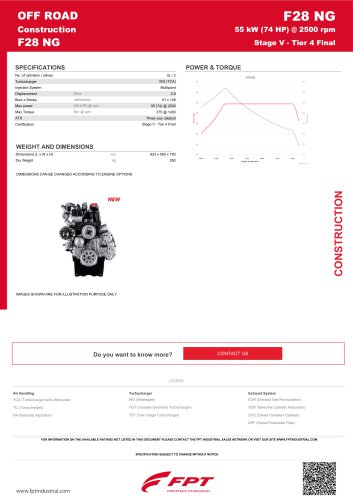

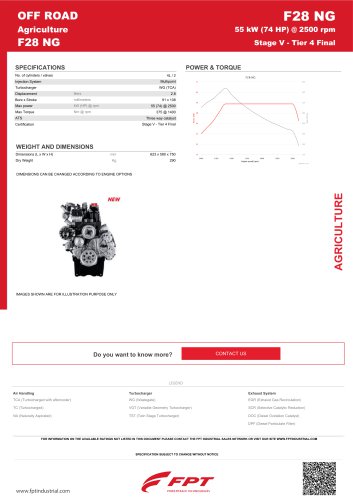

F28 NG-CONSTRUCTION

1 Pages

-

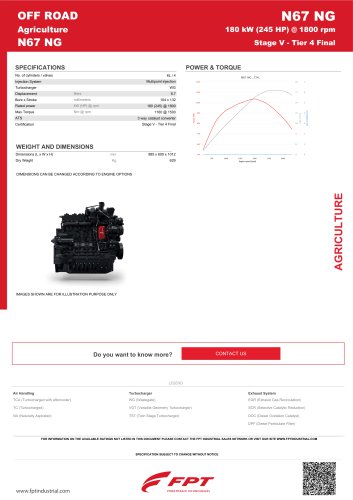

N67 NG-AGRICULTURE

1 Pages

-

F28 NG

1 Pages

-

CURSOR 9 NG-BUSES

1 Pages

-

XCURSOR 13 NG

1 Pages

-

XCursor 13

1 Pages

-

N67 NG-BUSES

1 Pages

-

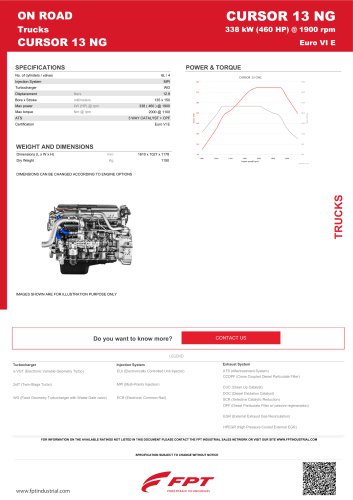

CURSOR 13 NG

1 Pages

-

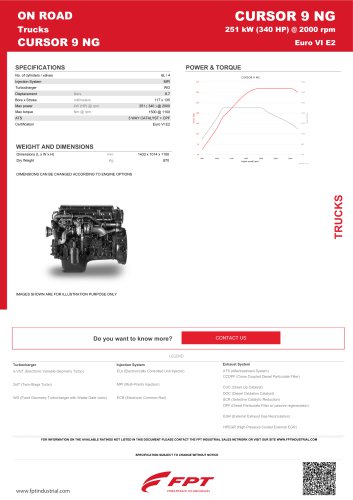

CURSOR 9 NG

1 Pages

-

N67 NG

1 Pages

-

WATER PUMP

6 Pages

-

TURBOCHARGER

6 Pages

-

STARTER MOTOR

6 Pages

-

SHORT BLOCK

6 Pages

-

OIL FILTER

8 Pages

-

LONG BLOCK

6 Pages

-

INJECTOR

8 Pages

-

HIGH PRESSURE PUMP

8 Pages

-

FPT GENUINE CYLINDER HEAD

6 Pages

-

FUEL FILTER

8 Pages

-

ALTERNATOR

10 Pages

-

Brochure MyFPT App

6 Pages

-

Brochure REMOTE ASSISTANCE

13 Pages

-

PROACTIVE ASSISTANCE

7 Pages

-

F1A 85 kW

1 Pages

-

N45

1 Pages

-

F1C NG

1 Pages

-

FPT INDUSTRIAL MARINE COMMERCIAL

27 Pages

-

S8000

1 Pages

-

GENERATOR SETS

20 Pages

-

ON ROAD

51 Pages

-

OFF ROAD CONSTRUCTION

33 Pages

-

MARINE

26 Pages

Archived catalogs

-

OFF ROAD AGRICULTURE 2022

37 Pages

-

OFF ROAD AGRICULTURE 2019

33 Pages

-

ON ROAD_2016

60 Pages

-

POWER GENERATION

70 Pages

-

MARINE

40 Pages