Catalog excerpts

MILK STANDARDIZATION

Open the catalog to page 1

OPTIMIZE YOUR RAW MATERIAL USAGE A common goal for milk standardization is to make the best use of raw materials and ensure that final products are as close to target specifications as possible, in terms of fat, protein and total solids. In this way, yield and profit can be improved with confidence while always meeting quality and legislative requirements. In-line process control allows yet more value to be gained from NIR analytical technology. By measuring directly in the process and getting results every few seconds, process variation of key parameters such as protein and total solids...

Open the catalog to page 2

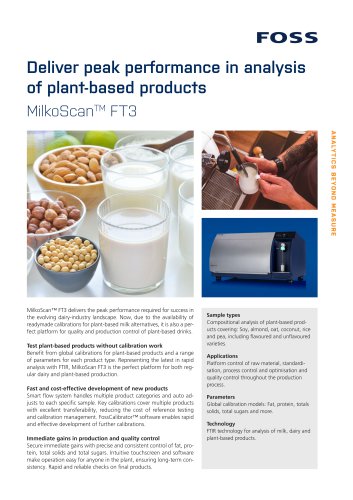

YOUR PASSPORT TO IN-LINE PROCESS CONTROL The ProFoss™ 2 solution builds on the success of the original ProFoss solution by exploiting the latest advances in analytical technology such as instrument calibration, connectivity for data sharing, probe design, full integration with a benchtop analyser such as MilkoScan™ FT3 for reference analysis and much more. With ProFoss 2, dairy producers can benefit from in-line NIR process analysis with the highest level of analytical performance across their production and quality laboratory setup. Achieve complete control of your milk standardization...

Open the catalog to page 3

IMPROVE YOUR MILK STANDARDIZATION PROCESS ANALYSIS ADVANTAGES • Production close to target specifications • Increased yield and profit • Less rework and start-up variation • Optimised mass-balance • Real-time process control • Process regulation for short term process changes AUTOMATIC PROCESS CONTROL WITH PROFOSS™ 2: % High or low protein source Reduce start-up variation. Cream or whole milk Skim milk Production closer to target. React in real-time on results out of spec. Standardized milk Control parameters Typical installation point Dedicated product interface • Installation as close to...

Open the catalog to page 4

CONTROL YOUR MILK STANDARDIZATION USING REAL-TIME ANALYSIS ProFoss™ 2 provides real-time analysis results enabling you to react immediately on process changes and significantly reduce your process variations. Move fat, protein or total solids targets closer to product specifications and increase yield, profit and quality. A high frequency of results ensures that nothing gets missed and that you will always have a precise picture of any fluctuations in the process. The ProFoss 2 lateral transmittance probe enables penetration deep into the product, allowing a larger product presentation to...

Open the catalog to page 5

PROFITABLE MILK STANDARDIZATION The reliability of measurements of fat, protein and total solids across all units and production lines is assured with standardized instruments that all measure the same. A standardized analyser with transferable calibrations significantly reduces the implementation and maintenance costs for in-line process control. The high uniformity standards and robust design of the latest generation ProFoss™ 2 solution ensures that the same calibration can be used on multiple instruments which measure the same product. This also ensures that only minimal updates to...

Open the catalog to page 6

PROFOSS™ 2 HIGH RESOLUTION NIR TECHNOLOGY ProFoss™ 2 is unique in employing a near infrared-based analysis technology known as high resolution diode array analysis. The high resolution technology ensures accuracy and reliability with measurements based on a high density of data points. PROFOSS™ 2: • High resolution diode array NIR technology for accurate and continuous analysis • Built-in instrument standardisation for quick and simple implementation • Unique lateral transmittance probe interface providing accuracy and rapid implementation • Quantitative and qualitative data for better...

Open the catalog to page 7

HIGHER YIELD ENSURED BY PREDICTABLE PERFORMANCE The latest technology behind ProFoss™ 2 ensures consistent performance day in, day out and year after year. Building on the reliable measurements delivered by each and every analyser unit, software and digital connectivity services help to maintain stable high performance across whole populations of instruments. Calibrations can be monitored and adjusted remotely from anywhere. Automatic instrument monitoring and alerts can be set up and maintenance schedules can be proactively planned for optimal uptime. Plant Manager QA Manager FOSS...

Open the catalog to page 8

A FAST RETURN ON INVESTMENT With any process analysis solution, you are effectively putting your production in the hands of technology. FOSS is the right partner to provide a reliable solution with consistently high uptime. ProFoss™ 2 is simple to install directly in the production line and comes with a total service solution to help protect your investment. SmartCare™ service and support plans offer the option of preventative maintenance for maximum uptime and minimized repair costs THE NEW PROFOSS™ 2 SOLUTION OFFERS: • Proven technology for precision and trouble-free operation •...

Open the catalog to page 9

DEDICATED PRODUCT INTERFACE LATERAL TRANSMITTANCE: The 3rd generation lateral transmittance probe does not restrict the flow rate of the product. It can easily be installed in the production line using a standard Varinline connection for installation in a pipe. In combination with the ProFoss™ 2 unit, it is perfect for in-line analysis of milk. PROFOSS™ 2, DESIGNED FOR PROCESS ENVIRONMENT AND PROCESS OPTIMISATION: ProFoss™ 2 is a flexible and easy-to-implement solution with key food safety certifications. Implementing ProFoss 2 provides insight into the process to help maximise production...

Open the catalog to page 10

TECHNICAL SPECIFICATIONS Measuring technology: Lateral Transmittance Analysis frequency Real time: Average analysis time per result 2 - 3 seconds Wavelength range Spectral dispersion Si Diode Array detector Process line interface Sapphire, 5 mm thick, with food grade FFPM O-ring seals Fits into standard GEA Tuchenhagen Varinline Access Units with Ø68 mm opening (Type N) Product temperature Product pressure Production pressure < 30 bar (< 435 PSI). Shock pressure < 75 bar (< 1088 PSI). Warning! Varinline access units higher than DN 80 permit a maximum pressure of 10 bar (145 PSI). Optical...

Open the catalog to page 11All FOSS catalogs and technical brochures

-

Infratec™

2 Pages

-

OIL PROCESSING SOLUTIONS

8 Pages

-

FEED SOLUTIONS

4 Pages

-

MycoFoss™

12 Pages

-

FOSS IN FEED

12 Pages

-

MycoFoss™ Datasheet

2 Pages

-

MilkoScan™ Mars

2 Pages

-

NIRS™ DS3 Dairy Analyser

2 Pages

-

FoodScan™ 2 Dairy

2 Pages

-

CombiFoss™ 7

4 Pages

-

BacSomatic™

2 Pages

-

MilkoScan™ FT3 Brochure

12 Pages

-

MilkoScanTM FT1

2 Pages

-

FOSS IN DAIRY

16 Pages

Archived catalogs

-

MilkoScan™ FT3 Specification

2 Pages

-

MilkoScanTM FT3

2 Pages