Catalog excerpts

Today even the most accomplished dairy producers face the challenge of getting more and more out of their raw materials while still improving their product quality. That is a tall order in an industry built on highly variable raw materials and quickly changing markets. But where nature is unpredictable, data harvests never fail. material to finished product. That is why we have spent the last 60 years developing and refining instruments that measure every little step of the way. We translate measurements into mathematical algorithms that power automated systems, optimise your manufacturing...

Open the catalog to page 3

ADD VALUE THROUGHOUT YOUR MANUFACTURING PROCESS Innovation in analytical technology over the past few decades has led to many new opportunities to control the dairy manufacturing process for improved profit and quality and, happily, the pace of development only gets faster. Let’s take a look at the options available to you in the production of different dairy products. Get more from your resources At FOSS we understand that success in the dairy industry is dependent on being able to deliver consistently high quality products. Our versatile range of analytical solutions has been designed to...

Open the catalog to page 4

Process control FOSS has over 50 years of experience in developing analytical instruments for dairy production. We know that you are working in an industry that faces continually changing consumer demands, concerns over food safety and rising regulatory requirements. Our solutions help you increase operational efficiency so you can meet these challenges. FOSS dairy solutions can test for: Fat, Protein, Lactose, Total Solids, Solids-non-Fat, Casein, Urea, Density, Freezing Point Depression, Sucrose, Fructose, Glucose, Galactose, Total Sugar, Lactic Acid, Citric Acids, Free Fatty Acids,...

Open the catalog to page 5

KNOW YOUR RAW MATERIAL AND IMPROVE QUALITY Raw material Another tanker of milk arrives, but what is it worth, how are you going to use it and is it safe? Rapid testing directly at intake with purpose-built FOSS analytical solutions helps you make best possible use of a milk supply that is ever-changing from supplier to supplier, from season to season and in some cases, also prone to accidental or deliberate contamination within the supply chain. The accurate information allows fair payment to suppliers and by knowing exactly what is on the way in, you can segregate before standardisation...

Open the catalog to page 6

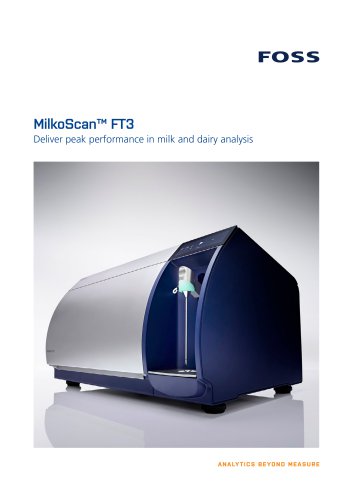

Tools for intake control Bench top Fourier Transform Infrared (FTIR) instruments such as MilkoScan™ Mars, MilkoScan™ FT1, MilkoScan™ FT2 and BacSomatic™ are ideal for intake control, for example in a laboratory or control room close to both intake and productio

Open the catalog to page 7

Tools for standardisation Standardisation requires rapid, accurate and routine analysis. The faster the results, the sooner the process can be adjusted. The more accurate the results, the closer adjustments to target values can be made. The more frequent the results, the better adjustments for sudden variations in composition. For high volume production, a process control instrument such as MilkoStream™ with regulation software is exceptional, providing virtually real time adjustment of the milk flow into production.

Open the catalog to page 8

STANDARDISE AND INCREASE PROFITABILITY Standardisation By standardising the components in your milk supply you can produce consistent quality regardless of the scale of your operation or seasonal variations in your raw material. Our solutions let you monitor and adjust the relationship between the different milk components, such as fat, protein, solids and casein for improved production. Standardisation at this early stage has been shown to improve yield, reduce waste and increase profit margins. For instance, in the production of whole milk with a required minimum 3.5% fat content, fat...

Open the catalog to page 9

IMPROVE YIELD THROUGH PROCESS CONTROL Process control FOSS offers a range of at-line and in-line analysis solutions for use at different stages throughout the production process. With rapid and reliable measurements of crucial parameters, you can leverage real-time production data and take action that saves costly rework and wastage of valuable resources. Better yield in butter If you are making butter, you will need to follow legislation stating that your butter must contain a maximum of 16% moisture or minimum 80% fat. The final composition of butter is adjusted by mixing more or less...

Open the catalog to page 10

Profit improvement: A powder production with output of 70,000 tonnes per year moves moisture closer to target by 0.1% leading to a yield increase worth €147,000. Effective evaporation for profitable powder When making milk concentrates and powders, the ratio between fat and solids in the milk must first be standardised to reach the specified proportions in the finished powder. Then it is all about increasing yield and revenue by checking and adjusting the protein to total solids ratio in the concentrate coming out of the evaporation process. which is much less expensive and more sustainable...

Open the catalog to page 11

Towards the perfect cheese making process During cheese making, rapid information about the moisture content of the intermediate cheeses is essential for controlling the various processing steps. Cutting, stirring and especially pressing processes all have great impact on the moisture content of the finished cheeses. Hard cheese The closer you can follow product composition during the production, the faster you can make corrective actions on subsequent batches. A rapid at-line analyser can substantially enhance the profitability of any cheese production. Fresh cheese In cream cheese or...

Open the catalog to page 12

versatile and robust for use at the production line or in the laboratory. The DairyScan™ is also ideal for cheese. And for powder, the NIRS™ DS2500 instrument is ideal for analysis of moisture content at the end of the drying process. In all forms of production, a stage is reached where volume determines whether an integrated process control system such as ProFoss™ or MilkoStream™ is worthwhile. Where a benchtop solution might be used once an hour, these increasingly popular process options provide a continuous flow of analytical results and thereby a greater opportunity to push the process...

Open the catalog to page 13All FOSS catalogs and technical brochures

-

Infratec™

2 Pages

-

OIL PROCESSING SOLUTIONS

8 Pages

-

FEED SOLUTIONS

4 Pages

-

MycoFoss™

12 Pages

-

FOSS IN FEED

12 Pages

-

MycoFoss™ Datasheet

2 Pages

-

MilkoScan™ Mars

2 Pages

-

NIRS™ DS3 Dairy Analyser

2 Pages

-

FoodScan™ 2 Dairy

2 Pages

-

CombiFoss™ 7

4 Pages

-

BacSomatic™

2 Pages

-

MilkoScan™ FT3 Brochure

12 Pages

-

MilkoScanTM FT1

2 Pages

-

PROFOSS™ 2 MILK STANDARDIZATION

12 Pages

Archived catalogs

-

MilkoScan™ FT3 Specification

2 Pages

-

MilkoScanTM FT3

2 Pages