Catalog excerpts

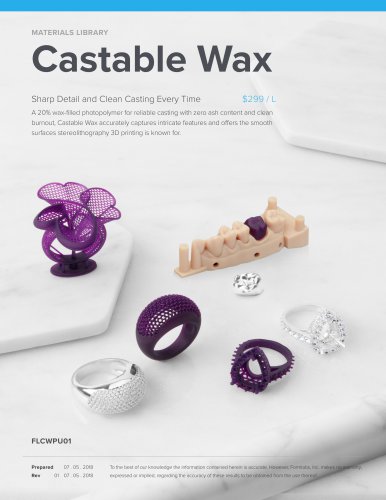

Introduction to Casting for 3D Printed Jewelry Patterns The way jewelers work is changing, and castable photopolymer resins are leading the way. From independent designers concepting and prototyping in their studios, to casting houses increasing capacity and diversifying their offerings, digital fabrication techniques are increasingly key to growing a successful jewelry business. In this guide, learn how to cast fine jewelry pieces from patterns 3D printed on the Form 2. Request a Sample Part 3D Printed in Castable Wax Resin › Learn About Casting and Jewelry Production from Formlabs ›

Open the catalog to page 1

What Is Direct Investment Casting? Direct investment casting, or lost wax casting, is a popular moldmaking technique that can be used to fabricate small and large parts in a wide variety of metals. Originating over 5,000 years ago, casting enables creators to work with a wide variety of materials and is one of the easiest ways to make metal parts. In investment casting, a hollow mold is created from a hand-sculpted or 3D printed master pattern. The master is immersed in a refractory casting material (or “investment”), which dries and hardens. The wax or 3D printed pattern is burned out,...

Open the catalog to page 2

Table of Contents Design for Casting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Print and Prepare Parts for Casting . . . . . . . . . . . . . . . . . . . . 5 Build the Sprue Tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Prepare the Mold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 Burnout and Casting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Burnout Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 Troubleshooting Checklist . . . . . . . . . . . . . . . . . . . . . . . . . 10 Learn More . . . . ....

Open the catalog to page 3

1. Design for Casting Use CAD software such as RhinoGold, JewelCAD, or 3Design to take your parts from concept to 3D printed pattern using these best practices. Design of traditional wax patterns and 3D printed resin patterns share many principles, such as the importance of smooth material flow. Where possible, avoid creating sharp corners that could increase turbulence. As with wax, orient the design so that it fills from larger voids to smaller channels and features. SPRUES While large feed sprues can be created with normal wax, small sprue channels may be 3D printed to save labor and...

Open the catalog to page 4

2. Print and Prepare Parts for Casting Jewelry patterns can be printed in large batches on the Form 2 desktop 3D printer. Packing the build platform with parts offers the best possible efficiency and throughput. After printing in your desired orientation, follow these steps to prepare the patterns for spruing and investing. washing Thoroughly washing parts in 90%+ isopropyl alcohol (IPA) is critical to a clean casting. Excess uncured resin can interfere with investment curing and will cause casting defects such as pitting. Allow the parts to fully dry after removing them from the IPA bath....

Open the catalog to page 5

3. Build the Sprue Tree Attach the post-processed prints to a main wax sprue with sticky sprue wax. Melt the wax to create smooth junctions between each printed pattern and its feed sprue. A wax heat pen makes it easier to join resin patterns to the wax sprue tree. Tip: Printed resin patterns do not melt. If you have difficulty joining a print to a wax sprue, try using a small amount of super glue or fast setting epoxy. Arrange thicker parts at the bottom and thinner parts at the top of the tree. 3D printed parts may require slightly more space between parts than a traditional wax tree. If...

Open the catalog to page 6

4. Prepare the Mold The following steps are a standard procedure for preparing any investment flask mold. A vacuum investing machine helps to evenly mix, degas, and pour the investment easily and cleanly. However, it is also possible to use a separate mixer and vacuum chamber. A ttach a casting flask to the sprue base. If the flask is perforated, wrap it with clear packing tape to contain the investment. S lowly pour the investment down the side of the flask, avoiding the pattern tree. A smooth pour is less likely to trap bubbles. Use a vacuum chamber to extract any bubbles from the flask....

Open the catalog to page 7

5. Burnout and Casting Place the casting flask in the burnout oven and heat using the recommended Burnout Schedule. Make adjustments depending on the investment instructions, flask size, and amount of printed material. If starting the burnout with a hot oven, make sure that the flasks have been resting for at least 5 hours, otherwise the plaster might crack when the water expands and turns into steam. Formlabs recommends using a well-ventilated furnace (with an inlet and an outlet), to provide sufficient air flow throughout the chamber and to safely exhaust all vaporized resin material....

Open the catalog to page 8

Formlabs offers Castable Wax and Castable Resins for jewelry investment casting. Castable Wax Resin is designed to offer improved flexibility in its burnout schedule, and casters should first and foremost follow the manufacturers instructions for their investment material when using Castable Wax. Castable Resin is a legacy product which requires a more specific, gentle burnout schedule. Recommended schedules for each material are shown below, for use with R&R Plasticast with BANDUST investment. phase time schedule °c schedule °f introduction to casting for 3d printed jewelry pattern

Open the catalog to page 9

increase amount of water added to investment. Small bubbles on casting Metal flashing or Jagged blobs on casting Porous surface on casting Partial fill on thin sections or filigree investment working time too short to fully degas flask Bubbles trapped against pattern investment too weak and cracked or damaged during burnout Metal shrinking during cooling, without a reserve of molten metal to draw from Metal freezing in mold Use cold water in mixture. Use a surfactant coating (debubblizer). Decrease amount of water added to investment. increase bench set time after investing. increase...

Open the catalog to page 10

Papilio Ring, LACE by Jenny Wu Learn More About Digital Jewelry Fabrication To learn more about Formlabs printers and Castable Wax Resin, speak with our team: https://formlabs.com/company/contact/ Casting is an involved process, so for best results, we suggest working with a casting specialist. To find our list of recommended casting houses, visit: https://formlabs.com/company/recommended-casting-houses Special thanks to Lars Sögaard Nielsen and the KEA (Copenhagen School of Design and Technology) for letting Formlabs document their casting process. RELATED RESOURCES Designing for 3D...

Open the catalog to page 11All Formlabs catalogs and technical brochures

-

Ceramic

2 Pages

-

Denture Base and Teeth

2 Pages

-

Draft Resin

2 Pages

-

MATERIAL DATA SHEET Durable

2 Pages

-

Elastic

2 Pages

-

MATERIAL DATA SHEET Flexible

2 Pages

-

Grey Pro

2 Pages

-

High Temp

4 Pages

-

Standard

3 Pages

-

Rigid

2 Pages

-

Tough

2 Pages

-

WHITE

15 Pages

-

DURABLE

3 Pages

-

DENTAL MODEL

3 Pages

-

Castable

8 Pages

-

BLACK

11 Pages

-

Solvent Compatibility

1 Pages

-

Flexible

2 Pages

Archived catalogs

-

Dental LT Clear

2 Pages

-

Dental LT Clear 2017

2 Pages