Catalog excerpts

Rotating Probe 6.481 1 Edition 09/00 Figure 1: Rotating Probe 6.481 Characteristics · low cost industrial probe system for eddy current flaw detection · designed for continuos work · high throughput rate thanks to high rotation speed (nmax=15.000 min-1) · simple system integration thanks to compact housing and low mass (m=1 kg) · maintenance-free drive through brush-free DC servo motor · high precision true running of probes rotor by double bearing · contactless signal transmission by rotating inductive transmitter (including clearance channel) · synchronization pulse in 60° steps · test frequency range 100 kHz .. 1 MHz · specially adapted probes available for different applications Probe System for Single-Channel Testing Rotating Probe 6.481.01-1xxx

Open the catalog to page 1

2 Rotating Probe 6.481 Edition 09/00 Applications · stationary application for non-destructive flaw testing of mass-produced parts, e.g. in automotive and supplying industry · direct integration into the production line · application in customer-specific test stations · suitable test electronics are STATOGRAPH S, STATOGRAPH CS, STATOGRAPH ECM, for more information about these systems see table below Designation Type Number Order Number STATOGRAPH S-System 6.420 135 774 3 STATOGRAPH ECM 6.421 103 583 5 STATOGRAPH CS 6.425 139 873 3 Mode of operation The eddy current probe element, consisting...

Open the catalog to page 2

Rotating Probe 6.481 3 Edition 09/00 The rotating probe is positioned close to the test specimens surface and rotates at high speed. In order to test the entire surface either the test piece can be moved past the rotating probe if the probe system is mounted stationary or the probe (which is mounted on a slide for instance) can be moved past the test surface if the test piece is fixed in test position. Figure 4: Example of a combined application of the Rotating Probe in wheel hub testing. Testing the flat surface for longitudinal and transversal defects by Rotating Probe T. Testing the...

Open the catalog to page 3

4 Rotating Probe 6.481 Edition 09/00 Bezeichnung 1 / Designation 1 Bezeichnung 2 / Designation 2 Ref. Sach-Nr./Subject-No Werkstoff/Material Date File SML UA Teile-Nr. / Part-No Sach-Nr. / Subject-No Blatt Freigabe Mod. f e d c b a g Date Scale INSTITUT Dr. Förster Name Format DIN A4 Adr. Micro Diese beiden Steuerkabel werden nur benötigt, wenn Sonderfunkt. (z.B. Ausblendung 60°) des Rotiersonden- Controllers benützt werden! In diesem Fall werden die Synchro-Kabel nicht benötigt!! folgende Prüfkabel können hier je nach Anwendung eingesetzt werden: z.B: 2.899.25-1103 (3m) 3.621.01-9901...

Open the catalog to page 4

Rotating Probe 6.481 5 Edition 09/00 Rotating Probe Controller For controlling the functions of the Rotating Probe a controller is necessary. There are two different versions available: Designation Type Number Order Number Application Rotating Probe Controller 6.481.01-1001 126 938 0 simple version with power switch, motor switch and control lights (power, motor, error); connecting socket for synchronization-cable (rot. sync.) to the test electronics Rotating Probe Controller 6.481.01-1011 145 999 6 extended version with additional connecting socket for control cable to transmit the...

Open the catalog to page 5

6 Rotating Probe 6.481 Edition 09/00 Possible Combinations for Connection The following combinations to connect a Rotating Probe are possible. STATOGRAPH ECM Line Driver Cable Adaptation Application no no very short distance (at maximum 1 m) between Rotating Probe and test electronics no yes the normal case; distance between Rotating Probe and Cable Adaptation at maximum 1 m; distance between Cable Adaptation and test electronics up to 100 m yes yes exceptional case; necessary only if limited space does not allow to mount the Cable Adaptation close to the Rotating Probe It is not possible...

Open the catalog to page 6

Rotating Probe 6.481 7 Edition 09/00 Synchronization Cable When using the simple version of Rotating Probe Controller 6.481.01-1001 in connection with the STATOGRAPH S/CS the Synchronization Cable 6.421.01-9903 is mandatory to connect the Adapter 6.420.26-9712 or 6.420.21-9718. Control Cable M When using the extended version of Rotating Probe Controllers 6.481.01-1011 in connection with the STATOGRAPH S/CS the Control Cable M 6.410.01-9916 serves to transmit the extended functions (Rot.Sync., masking, error condition, motor on/off); in this case the Synchronization Cable 6.421.01- 9903 is...

Open the catalog to page 7

8 Rotating Probe 6.481 Edition 09/00 Technical Data Rotating Probe testing method DIN 54 140 eddy current dimensions see Figure 6 mass approx. 1,0 kg protection class IP 53 permitted operating temperature +5°C ... +40°C maximum rotating speed 15.000 min-1 Rotating Probe Controller dimensions (L x W x H) approx. 400 x 230 x 110 mm3 mass approx. 6,5 kg protection class IP 53 permitted power supply 230 V~ / 50 Hz nominal power 300 VA permitted operating temperature +5°C ... +40°C Adapter dimensions approx. 230 x 200 x 110 mm3 mass approx. 3,5 kg protection class IP 53 permitted operating...

Open the catalog to page 8

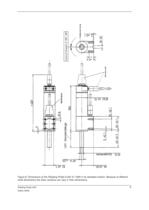

Rotating Probe 6.481 9 Edition 09/00 Figure 6: Dimensions of the Rotating Probe 6.481.01-1600 in its standard version. Because of different shaft dimensions the other versions can vary in their dimensions.

Open the catalog to page 9

10 Rotating Probe 6.481 Edition 09/00 Product Information Leaflets Title Order Number Automatic wheel hub crack tester 9.251.01 126 945 3

Open the catalog to page 10All Foerster Instruments catalogs and technical brochures

-

STATOGRAPH® DS 6.440

12 Pages

-

DEFECTOMAT

8 Pages

Archived catalogs

-

Probe Catalog

26 Pages

-

STATOGRAPH TOUCH PROBES leaflet

14 Pages

-

MAGNATEST ECM CE leaflet

6 Pages

-

MAGNATEST ECM leaflet

6 Pages

-

Fine Wire Inspection System

1 Pages

-

MAGNATEST brochure

4 Pages

-

CIRCOFLUX brochure

6 Pages

-

CIRCOSCAN leaflet

20 Pages

-

CIRCOGRAPH DS leaflet

12 Pages

-

DEFECTOMINI leaflet

8 Pages

-

Sensor system T leaflet

15 Pages

-

Sensor system M leaflet

26 Pages

-

Sensor system P leaflet

14 Pages

-

Sensor system H leaflet

12 Pages

-

DEFECTOMAT ECM leaflet

6 Pages

-

DEFECTOMAT DI brochure

4 Pages

-

DEFECTOMAT CI brochure

4 Pages

-

DEFECTOMAT DS

14 Pages