Catalog excerpts

The Flygt N-technology pump series for water and wastewater HIGH EFFICIENCY WITH CLOG-FREE PERFORMANCE

Open the catalog to page 1

No clogging. No wasted energy. Just trouble-free pumping Our Flygt N-pumps (1.3 kW – 680 kW) are designed to handle the world’s toughest water and wastewater applications. And now, with our Adaptive N™ technology in all smaller pumps, you get a superior way to avoid clogging, reduce unplanned maintenance and cut your energy bills. That adds up to total peace of mind – and big savings over the long term. Our vast fluid handling knowledge and dedication to research and development leads to technological advances and continuous improvement. That’s why Flygt N-pumps are currently at work in...

Open the catalog to page 2

N-pump application • Wastewater • Stormwater • Desalination • Reuse • Sewage • Treatment Plant Broad capacity • Ratings from 1.3 kW to 680 kW • Discharge up to 800 mm • Flow up to 1,000 l/s • Heads up to 100 m • Submersible and dry installations • Every Flygt pump is performance tested in the factory • Can handle dry solids up to 8% Key benefits • State-of-the art pumping with Adaptive N™ technology • Sustained high-efficiency operation • Modular design with high adaptation grade • Lowers energy and unplanned maintenance costs • Reduces total lifecycle cost of the i

Open the catalog to page 3

Advanced technology guides the design of every component From the motor and seals to the shaft and impellers, every component in a Flygt N-pump is designed, engineered and manufactured to optimize operation and prolong service life. Advanced technology guides the design of all aspects of the pump. One example is the Adaptive N hydraulic system, which is available only with lower-capacity pumps. The fundamental N-technology, which was pioneered by Flygt, has been incorporated into our pumps for years. A more recent innovation is our Adaptive N impeller and Adaptive N hydraulic technologies...

Open the catalog to page 4

Adaptive N – lifts up for large objects When larger objects enter the pump, the impeller lifts up due to the forces from these solid objects passing through. This avoids clogging and assures continuous, energy-efficient pumping. Grey iron Duplex stainless steel Hard-Iron™ Choice of impeller materials With our Adaptive N impeller, you can also choose the optimal material type for your needs: Hard-Iron™, grey iron or stainless steel. Flygt’s patented Hard-Iron alloy is developed specifically for tough wastewater applications. Accelerated wear 0 20 40 60 80 tests prove that Hard-Iron (60 HRC)...

Open the catalog to page 5

1. Better heat transfer Our specially designed and manufactured motor provides enhanced cooling because heat losses are concentrated around the stator. Trickle impregnated (not applicable for 3069) in resin (Class H insulation), the stator windings are rated at 180°C (355°F) and enable up to 30 starts per hour. 2. Cable entry Water-resistant cable entry provides both sealing and strain relief functions to ensure a safe installation. 3. Sensors Thermal sensors embedded in the stator windings prevent overheating. Optional leakage sensors in the stator and oil housings are also available. 4....

Open the catalog to page 6

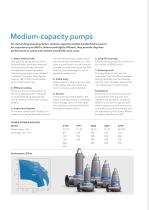

Medium-capacity pumps For demanding pumping duties, medium-capacity models handle fluid transport for capacities up to 500 l/s. Robust and highly efficient, they provide clog-free performance to achieve the lowest overall life-cycle costs. 1. Better heat transfer Our specially designed and manufactured motor provides enhanced cooling because heat losses are concentrated around the stator. Trickle impregnated in resin (Class H insulation), the stator windings are rated at 180°C (355°F) and enable up to 30 starts per hour. 2. Efficient cooling These pumps are cooled either by the surrounding...

Open the catalog to page 8

High-capacity pumps When higher capacity is required, the Flygt N-pump series has pumps to do the job. These models deliver unprecedented pumping power – reliably and efficiently. 1. Better heat transfer Our specially designed and manu factured motor provides enhanced cooling because heat losses are concentrated around the stator. Trickle impregnated in resin (Class H insulation), the stator windings are rated at 180°C (355°F) and enable up to 15 starts per hour. 3. Cable entry Water-resistant cable entry provides both sealing and strain relief functions for a safe installation. 4. Sensors...

Open the catalog to page 10

Install it and control it just the way you want it Regardless of the size or type of N-pump you require, we offer a wide range of modular installation concepts as well as purpose-built monitoring and control systems. Our modular installation concepts let you customize inlets and outlets to fit your needs exactly. MAS 801 – the smart way to monitor performance This new pump moni oring system t offers powerful data management capabilities to ensure you are constantly updated on each pump’s conditions and operational status. We’ve removed the traditional sensor cable, which means simplified...

Open the catalog to page 12

Take advantage of our design and engineering expertise Are you getting the most out of your pump station designs? If you have questions regarding fluid dynamics, optimizing your sumps, water hammer calculations or even service, we can help. Flygt engineers have been researching and designing pump stations for over three decades to achieve the lowest life-cycle costs. And we have a strong service network to support you. One of the biggest challenges in designing a pump station is to achieve a balance between efficiency and performance. Often times, pump stations are over-designed, resulting...

Open the catalog to page 13

Complete pre-engineered solutions for all your needs Even better together Do you need a swift station rollout in a municipal or commercial area? You'll be happy to know that we offer a wide range of pre-engineered packaged pump stations that make the job easier and more cost-efficient. Ideally suited for our premium N-pumps, Flygt packaged pump stations come with piping and valve systems, all installation accessories and monitoring and control equipment. Trouble-free pumping in a package Available in a range of designs, sizes and materials, our packaged pump stations feature a common...

Open the catalog to page 14All FLYGT catalogs and technical brochures

-

Flygt 2610

2 Pages

-

Flygt 2400.402

2 Pages

-

Flygt 2201.011

2 Pages

-

Flygt 2125.320

2 Pages

-

Flygt 2125.181

2 Pages

-

Flygt 2075.324

2 Pages

-

Flygt 2071.010

2 Pages

-

Flygt FGC 400

3 Pages

-

Liquid Manure Technology

20 Pages

-

Flygt C-pumps 3068–3800

8 Pages

-

Flygt mid-size mixers

4 Pages

-

Flygt Top-Entry Agitators

8 Pages

-

Flygt low-speed mixers

8 Pages

-

Flygt jet mixers

8 Pages

-

compact mixers

8 Pages

-

Hydrovar®

8 Pages

-

PumpSmart, PS200

8 Pages

-

AquaView

2 Pages

-

START 350

20 Pages

-

APP 500

4 Pages

-

ATU Alarm transmitters

4 Pages

-

Flygt compit pump stations

4 Pages

-

Flygt Epsilon range

8 Pages

-

Flygt widethroat W range

8 Pages

-

Flygt D-8000

4 Pages

-

Flygt D-8200

4 Pages

-

Flygt N-pump series

16 Pages

-

Flygt F-pump series

8 Pages

-

Flygt C-pumps 3068-3800

8 Pages