Website:

FLUX-GERÄTE GMBH

Website:

FLUX-GERÄTE GMBH

Group: FLUX-GERÄTE GMBH

Catalog excerpts

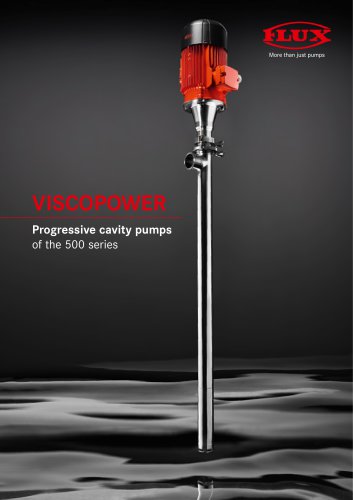

More than just pumps VISCOPOWER Progressive cavity pumps of the 500 series

Open the catalog to page 1

VISCOPOWER The FLUX VISCOPOWER progressive cavity pump pumps low-viscosity to high-viscosity media at up to 100 000 mPas. Examples of media Virtually all media, from low-viscosity to high-viscosity and pasty, media that is sensitive to shearing and even media containing solids can be pumped with the VISCOPOWER. And the pump can be used in all sectors such as industry, chemicals, hygienic, pharmaceuticals and cosmetics. Even media that is not capable of flowing can be pumped with ease when the pump is combined with the FLUX VISCOFLUX lite and VISCOFLUX mobile S drum-emptying systems. Paints...

Open the catalog to page 2

Properties and design The VISCOPOWER progressive cavity pumps were developed with a focus on making the medium-contacting wetted surfaces especially easy, intuitive and quick to dismantle and clean. The well thought-out design allows the pump to be dismantled quickly and effortlessly. Seals and contours are designed to minimise dead space. These properties make the pump highly suitable for use in the food, cosmetics or pharmaceutical industry. Dismantled in just 30 seconds faster to assemble/ disassemble as there are fewer parts! Flexibly constructed for the future Could your requirements,...

Open the catalog to page 3

Power lies in the detail Every last detail of the VISCOPOWER has been thought through. It delivers up to 87 % more pumping pressure and, thanks to four different rotor geometries, up to 60 % more pump capacity. But not only has the range of options grown, many details of the FLUX VISCOPOWER make work easier and safer. Everything from the bayonet fitting for the motor flange version to suction protection for inliners. VISCOPOWER F 570 and F 580 can be run with many drive motors; be it commutator motors, three-phase motors, compressed air motors or brushless motors. F 570 with two-stage...

Open the catalog to page 4

Use in an industrial application Low-viscosity, high-viscosity, pasty, viscous or highly flammable – the requirements faced in industrial applications are hugely varied. Thanks to its modular design, the VISCOPOWER can be perfectly matched to even the most demanding pumping job. Common industrial applications for the VISCOPOWER include filling and decanting oils, lubricants, paints, resins, hardeners, glues and much more. Production of fertiliser Decanting liquid plant fertiliser from IBCs into various containers for further processing. Desired pump capacity > 20 l/min VISCOPOWER F 570 with...

Open the catalog to page 5

Use in a hygienic application The VISCOPOWER makes light work of the stringent requirements applicable in the hygiene sector – thanks to its design with minimal dead space, the use of a closed mechanical seal and electropolished surfaces. It satisfies the EU standard (EC) 1935/2004 and (EU) 10/2011, FDA and 3A standards as well as the ATEX directives. Typical areas of use in the hygiene sector include Vaseline, wool fat, creams, tomato purée, juice concentrates, honey and much more. Filling agave syrup or juice concentrates from IBCs into stainless steel canisters for further processing...

Open the catalog to page 6

For more than 70 years, FLUX has been producing pumps, motors and accessories only in Germany. With its own production facilities, welding shop, motor winding room, plastic injection moulding unit and assembly workshop in Maulbronn, southern Germany, FLUX can rightly claim 100 % MADE IN GERMANY. The recipe for the success of FLUX’s exemplary product quality is a low staff turnover, a family-like sense of belonging, staff with decades of experience as well as continually training the next generation of workers. “Here in assembly, everything comes together. We have to handle every single...

Open the catalog to page 7

Accessories and special equipment FLUX VISCOFLUX drum-emptying system Single-vendor solution: to supplement our huge range of pumps, FLUX also supplies an extensive range of accessories. This ensures smooth and safe operation as well as simplifying the task in hand. No matter whether intended for mobile or stationary use – FLUX accessories turn a FLUX pump into a tailored delivery system for any application and purpose. And FLUX has developed the VISCOFLUX family for pasty media, media that does not flow and where the VISCOPOWER alone comes up against the limits of its capabilities. The...

Open the catalog to page 8

Today the FLUX name is recognised around the globe as the trademark for top standards in pump technology. Everything started with the invention of the electric drum pump in 1950. Nowadays FLUX has an extensive range of products each of which can be customized. FLUX pumps are used for example in the chemical and pharmaceutical industries; in machinery and plant engineering as well as companies in electroplating, effluent treatment and the foodstuffs sector. Whether single-product or system solution – FLUX quality is synonymous with a long service life, excellent economy and maximum safety....

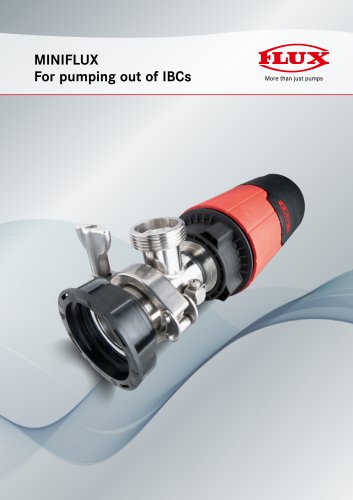

Open the catalog to page 9All FLUX-GERÄTE GMBH catalogs and technical brochures

-

Air-operated diaphragm pumps FDM

20 Pages

-

Flow meters

24 Pages

-

VISCOFLUX mobile S

12 Pages

-

FLUX Product overview

36 Pages

-

Brochure SAFETEC

8 Pages

-

Technical Data PERIPOWER

8 Pages

-

VISCOFLUX lite

4 Pages

Archived catalogs

-

Mixers

8 Pages

-

Drum pumps F/FP 425

4 Pages

-

Drum pumps F/FP 430

6 Pages

-

FLUX FOOD Flyer

6 Pages

-

Hand nozzle

2 Pages

-

ibc-solutions

6 Pages

-

Resistance chart

28 Pages

-

AdBlue

4 Pages

-

FLUX Mixers

2 Pages

-

FLUX Flow meter FMO 150

6 Pages

-

FLUX Flow meter FMO 140

6 Pages

-

FLUX Flow meter FMO 110

6 Pages

-

FLUX Flow meter FMO 104

6 Pages

-

FLUX Flow meter FMO 102

6 Pages

-

FLUX Flow meter FMO 101

6 Pages