Catalog excerpts

...profiling the anti-reflection (sputtering) coating process NEW VB7400 rrier Vacuum thermal ba rmance and with better perfo no out-gassing BUILDING ON THE BEST The Datapaq® SolarPaq system has been designed to monitor the product temperature profile as the photovoltaic (PV) cells pass through the plasma coating process. Working with major equipment manufacturers, a profiling system has been designed that can pass through the process chambers, measuring the cell temperatures even with the plasma activated. This feature, combined with the unique ability to be slotted straight into an un-modified cell carrier, enables profiling to be conducted without disrupting normal production. Monitoring the silicon nitride coating process is key to optimizing it and hence, to the final efficiency of the cell. Due to the nature of the processing equipment, this process was until now, very difficult and costly to measure. The Datapaq system can pass through the entire process measuring temperatures of the cell surface, thus providing data on what is happening at all points inside the process. A COMPLETE SOLUTION The custom designed logger and its thermal protection are easily placed into the cell carrier. This design enables the system to occupy one of the 156 mm (6.1 in) positions, so there is no need to modify the carrier. The system then passes through the entire process with plasma fields energized, and on exiting the process, the temperature profile information can be downloaded and analyzed. The system has been specifically designed to withstand harsh thermal and electrical environments within the plasma chamber, and can be used repeatedly for both process set-up and regular monitoring. The VB7400 makes use of a unique reflective plate insulation technology. This guarantees there is no outgassing from the profiler system so ensuring the process runs under normal conditions. BENEFITS • Fits in a cell position – no need to modify cell carrier • rofiles cell temperatures with the plasma energized, for accurate P reporting of process conditions during production • rovides accurate, repeatable results for optimizing your process P • aves time and money setting up or adjusting the process S SOLAR INSIGHT™ SOFTWARE This all new software has been designed specifically for use within the photovoltaic (PV) solar industry and contains many process-specific analysis displays. Wizards guide the users step-by-step to quickly obtain the data and analysis of the required results. This ensures that both experienced and novice users can obtain maximum benefit in the shortest poss

Open the catalog to page 1

TECHNICAL SPECIFICATIONSTHERMAL BARRIER VB7400 Dimensions (H x W x L) 18 mm x 146 mm x 146 mm (0.71 in x 5.75 in x 5.75 in)Weight880 g (1.75 lb) Material 100% stainless steel construction (only for use in vacuum applications) * Guidelines only actual performance will depend on vacuum level. (Securing flanges 10 mm/0.39 in wide) Using the spacer blocks provided with the barrier, the height above and below the carrier frame can be set to suit the process chamber being profiled. DATA LOGGER The Datapaq Q18 logger features rugged, reliable and accurate data acquisition circuits, clear...

Open the catalog to page 2All Fluke Process Instruments catalogs and technical brochures

-

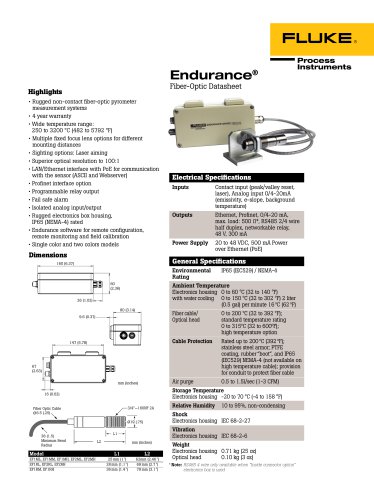

Endurance Datasheet 2024

3 Pages

-

Thermoview TV30

4 Pages

-

Datapaq TP6

4 Pages

-

Raytek®CM

4 Pages

-

MP Linescanner Series

4 Pages

-

Reflow Tracker®

4 Pages

-

Endurance Datasheet 2020

4 Pages

-

Datapaq® DP5

4 Pages

-

ThermoView TV40 Brochure

4 Pages

-

Datapaq Food Tracker System

4 Pages

-

DATAPAQ AutoPaq

2 Pages

-

DATAPAQ Furnace Tracker

4 Pages

-

Raytek XR Datasheet English

2 Pages

-

Compact CM Datasheet English

2 Pages

-

Thermocouple range 2

2 Pages

-

DATAPAQ XDL12

2 Pages

-

DATAPAQ Kiln Tracker System

4 Pages

Archived catalogs

-

Raytek Compact series MI3

4 Pages

-

Raynger 3i Plus Datasheet

4 Pages

-

Thermocouple range 1

2 Pages

-

Oven Tracker XL2 Data Logger

2 Pages