Catalog excerpts

Process Imaging System GS150 GS150LE Infrared Temperature Measurement for Glass Processes Benefits ■ Quickly find material defects and failed heating elements ■ Significantly reduce setup time ■ Automate quality monitoring for ISO 9000 ■ Improve profitability and product quality ■ Reduce scrap Quality Monitoring for Glass Processes ■ Detailed thermal images based on 40,000 measurement points per second ■ Automatic emissivity correction for low emissivity glass with GS150LE ■ Define product-specific configurations (recipes) ■ Customize and display zones overlayed on thermal image ■ Play back stored files as “movie” ■ PC independent alarms ■ Integrated OPC server for remote system control ■ Analog or digital output modules ■ On board Ethernet TCP/IP communication ■ Built-in laser sighting ■ Multiple language support The GS150 System is an automated temperature measurement system for glass bending, forming, annealing, and tempering processes. Core of the system is the MP150 linescanner. The MP150 measures a line of up to 1024 points using a rotating mirror that scans a 90° field-of-view up to 150 times per second. The high scan rate allows rapid detection of temperature non-uniformities and hot spots. The scanning of a glass part is initiated by the measured temperature, or an external “trigger’ signal. As each heated glass part traverses the field-of-view, a two-dimensional thermal image or “thermogram” is formed. The system software provides features to sub-divide thermal images from MP150 into portions of specific interest, the zones. The zone grid overlaid on the thermal image represents the heating elements in the furnace. Temperatures in each zone can be processed for a certain math function like average, maximum, or minimum temperatures. In case of a thermal defect, the software triggers an alarm. For later analysis, the thermal image is automatically stored in a separate file. The alarm can also be output with an optional digital output module. Through the use of OPC (OLE for Process Control), the GS150/GS150LE system acts as an OPC server and communicates with many common process control systems. This feature allows the GS150/GS150LE to move beyond being just a measurement tool and to become an integral part of the total process control system.

Open the catalog to page 1

Specifications Temperature Range 100 to 950°C (212 to 1742°F) System Accuracy ±0.5°C or ±3°C (6°F) Optical Resolution 170:1 (90% energy) Ambient Temp. 0 to 50°C (32 to 122°F), with water cooling 180°C (356°F) Field of View 90° Points per Line up to 1024 pixels Scan Rate up to 150 Hz The GS150LE system for low emissivity glass with automatic emissivity correction The GS150LE incorporates all features of the proven Raytek GS150 System. It is suited for monitoring and optimizing glass treatment processes (e.g. tempering and one-sided coated glass). Coated glass has very low...

Open the catalog to page 2All Fluke Process Instruments catalogs and technical brochures

-

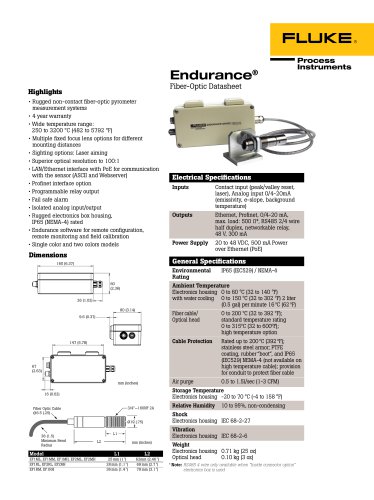

Fiber- Optic

3 Pages

-

Thermoview TV30

4 Pages

-

Datapaq TP6

4 Pages

-

Raytek®CM

4 Pages

-

MP Linescanner Series

4 Pages

-

Reflow Tracker®

4 Pages

-

Endurance Series

4 Pages

-

Datapaq® DP5

4 Pages

-

ThermoView TV40 Brochure

4 Pages

-

Datapaq Food Tracker System

4 Pages

-

DATAPAQ AutoPaq

2 Pages

-

DATAPAQ Furnace Tracker

4 Pages

-

Raytek XR Datasheet English

2 Pages

-

Compact CM Datasheet English

2 Pages

-

Thermocouple range 2

2 Pages

-

DATAPAQ XDL12

2 Pages

-

DATAPAQ Kiln Tracker System

4 Pages

Archived catalogs

-

Raytek Compact series MI3

4 Pages

-

Raynger 3i Plus Datasheet

4 Pages

-

Thermocouple range 1

2 Pages

-

Oven Tracker XL2 Data Logger

2 Pages