Catalog excerpts

EIMCO Extractor Horizontal Belt Filter

Open the catalog to page 1

Applications of horizontal belt filters Horizontal Belt Filters Should Be Used When: Thorough cake washing is required with • Free settling solids • Complete processing of feed materials • Maximum product recovery • Minimum operating cost A flexible range of operating conditions is required Simplicity of operation and maintenance are required Process contact requires exotic construction materials EIMCO’s Experience Since 1961, when the first EIMCO® Extractor® Horizontal Belt Filters were built, more than 700 units have been supplied worldwide, far more than any other manufacturer. FLSmidth...

Open the catalog to page 2

A. Feed slurry is uniformly distributed over the full width of the filter by a top feed arrangement. This eliminates cake formation problems associated with fast settling material. Gravity helps reduce vacuum energy and cake formation time. Several types of feed box arrangements are available, tailored to the process requirement. B. Cake travels with the filter media which is supported by the rubber drainage belt. Dewatering is accomplished by applying vacuum to the bottom of the drainage belt. C. Differential pressure draws slurry liquor through the filter cloth, along channels in the...

Open the catalog to page 3

Features & benefits FLSmidth utilizes two designs for the belt-edge seal: 1. Flexible flanges fold down when passing over the pulleys. Both flanges are vulcanized to the edge of the drainage belt. 2. Elastomer lips are raised in the filtration zone and may be supplemented by staticsideboard seals. Belt speeds up to 200 feet per minute. Fast filtration cycles minimize cake thickness for maximum production, and cake washing efficiency and drying. By controlling the speed of the filter and process conditions, cake thickness can be varied from 1/16 of an inch to 8 inches. Low maintenance Heavy...

Open the catalog to page 4

All phases of design and manufacturing are closely monitored according to strict, documented quality control procedures. Customers are invited to witness the factory test prior to shipment. Because most units are shipped fully assembled, installation costs are minimal. Often, all that is required at the installation site are basic foundation preparation and necessary hookups. Our team can also size and provide all necessary vacuum accessories for a complete turn-key system. Parts & service FLSmidth is dedicated to keeping units functioning at peak performance. Critical replacement items are...

Open the catalog to page 5

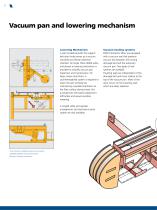

Vacuum pan and lowering mechanism Lowering Mechanism A pan located beneath the support belt drain holes serves as a vacuum manifold and filtrate collection chamber. On larger filters (4600 series and above) a lowering mechanism is provided to simplify vacuum pan inspection and maintenance. On large, severe duty filters, a counterweighted system is required to lower the pan vertically. By maintaining a parallel orientation to the filter surface during travel, this arrangement eliminates realignment difficulties and assures positive reseating. A hinged cable and capstan arrangement and...

Open the catalog to page 6

Fixed-seal systems incorporate a center rib vulcanized to the drainage belt and a slide strip attached to the vacuum pan. Most of the wear occurs on the slide strip material which can be replaced at regular, predictable intervals, minimizing unscheduled maintenance. Both systems are equipped with liquid lubrication on the slide material, with injection points at regular intervals along the length of the filter. In addition to lubricating the surfaces, the liquid seals against air ingress and cleans the seal surface.

Open the catalog to page 7

Filter Cloth Wash Drainage Belt Wash Cake Wash Box Feed Box Drainage Belt Filter Cloth Filter Cloth Aligning Mechanism 8. Filter Cloth Take-Up 9. Discharge Roll 10. Drive Pulley 11. Take-Up Pulley 12. Vacuum Pan 13. Filter Support Frame Copyright ©2010 FLSmidth A/S. ALL RIGHTS RESERVED. FLSmidth is a (registered) trademark of FLSmidth A/S. This brochure makes no offers, representations or warranties (express or implied), and information and data contained in this brochure are for general reference only and may change at any time. Minerals Processing Technology Center FLSmidth Salt Lake...

Open the catalog to page 8All FLSmidth Dorr-Oliver Eimco catalogs and technical brochures

-

Decanter™ centrifuges

4 Pages

-

FLS Discover Mining

19 Pages

-

Caricamat

7 Pages

-

Pneumapress

8 Pages

-

Tailings dewatering press

8 Pages

-

EIMCO AFP IV Filter Press

4 Pages

-

ABON Low Speed Sizers

8 Pages

-

TST jaw crusher

8 Pages

-

Gyratory Crushers

8 Pages

-

Cement plant upgrades

12 Pages

-

HIGHLIGHTS 2016

32 Pages

-

Flotation technology

16 Pages

-

Screen Media

24 Pages

-

KREBS® millMAXTM Pumps

8 Pages

-

Precious Metals Capabilities

7 Pages

-

QCXRoboLab Minerals

24 Pages

-

Mineral Processing Solutions

16 Pages

-

Top service gyratory crusher

8 Pages

-

MHC Twin shaft breaker

4 Pages

-

EV crusher retrofit

4 Pages

-

EV hammer impact crusher

8 Pages

-

Crushing Systems

20 Pages

-

Shriver Filter Press

8 Pages

-

Horizontal Belt filter

4 Pages

-

Dry Process Sampling

9 Pages

-

QCX/RoboLab - Minerals

13 Pages

-

QCX/RoboLab - QCX/Autoprep

2 Pages

-

Centaurus

5 Pages

-

Automation of Train Loader

3 Pages

-

Automation Solutions

11 Pages

-

ECS/ControlCenter

15 Pages

-

Milling of metal samples

5 Pages

-

BulkExpert

7 Pages

-

HyLogging

5 Pages

-

FT Grinding Mills

4 Pages

-

Grinding Mills

8 Pages

-

Screens Brochure

7 Pages

-

Portable Conveyor

1 Pages

-

Morenci

1 Pages

-

Los Filos

1 Pages

-

Zaldivar

1 Pages

-

Radomiro Tomic

1 Pages

-

El Tesoro

1 Pages

-

El Abra

1 Pages

-

Preheater calciner systems

8 Pages

-

Gas Suspension Absorber

9 Pages

-

World Cement Article

3 Pages

-

FabriClean™

34 Pages

-

Hydrocyclones

4 Pages

-

Feeder Breakers

8 Pages

-

HDP Beltpress Filters

8 Pages

-

Raptor XL1100 Brochure

8 Pages

-

Raptor XL300/XL400 Brochure

12 Pages