Website:

Flowserve SIHI Pumps

Website:

Flowserve SIHI Pumps

Group: Flowserve

Catalog excerpts

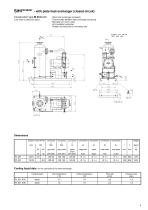

Vacuum-Compact Systems S\H\modular PL 251 M 33 to 1013 mbar 100 to 280 m3/h Pressure range: Suction capacity: DESIGN AND CONSTRUCTION The SiHImodu,ar systems consist of a various components which are assembled together to form a compact unit. Each unit can be varied in accordance with the respective application. The LEM liquid ring vacuum pump utilised in these systems is of a single stage design and of a simple and robust construction with the following features: • Non polluting due to near isothermal compression • Oil free, no lubrication in the working chamber • Capable of handling nearly all gases and vapours • Small quantities of entrained liquid can be handled • Easy to maintain and reliable operation • Low noise and virtually free from vibration • Anti cavitation protection as standard The SIHImodular systems are offered as a service liquid saving arrangement and can be supplied with or without a heat exchanger. APPLICATION As with the other SIHI liquid ring vacuum pumps this type is also capable of handling dry and saturated forms of gases. Small quantities of entrained liquid in the suction gas stream can also be dealt with. The SIHImodular is designed for vacuum applications of between 33-900 mbar, however, this range can be extended when used in conjunction with the respective gas operated ejector. (See standard catalogue for details). During its operation, the liquid ring vacuum pump must be continuously supplied with service liquid, normally water, in order to eliminate the heat resulting from the gas compression, and to prevent the pump from dry running operation. The service liquid is separated from the process gas in a separator. Dependent on the chosen arrangement and proposed application, the necessary service liquid can be either totally or partially recirculated within the system, conserving the amount of fresh make up liquid required. However, when using the total recirculated arrangement, the operating suction pressure must be 800 mbar or lower. The direction of rotation is clockwise when viewed from the drive end of the pump. GENERAL TECHNICAL DATA The combination of several limiting values is not admissible. *) In this case special measures should be taken for the separator.

Open the catalog to page 1

SIHImodular - Construction types with combined liquid service without heat exchanger Vacuum compact system equipped with: Manual service liquid regulation Ball type non-return valve Anti cavitation protection Mounting feet or rubber or mounting rails Designation M 10 0 (Low Cost-construction type) Additional options: as above, but thermostatic service liquid regulation (regulating range 0 - 30 °C) Designation M 15 0 (Base-construction type) as above, but with service liquid low level monitoring device for conductive liquids Designation M 20 0 (High Class-construction type) as...

Open the catalog to page 3

Suction volume flow and power absorption PL 251 M suction volume flow suction pressure power absorption suction pressure The operating data are applicable under the following conditions: pumping medium: service liquid: - dry air: - water vapour saturated air: Discharge pressure 1013 mbar (atmospheric pressure) The suction volume flow is applied to the suction pressure Tolerance of the operating data 10% Max. fresh water need with lowest suction pressure

Open the catalog to page 4

Construction type M 10 0 with: - Manual service liquid regulation (Low Cost-construction type) - Ball type non-return valve - Anti cavitation protection - Rubber mounting feet or mounting rails Fresh water requirements in [m3/h] dependent on suction pressure, speed and difference in temperarture FB = fresh service liquid KB = combined service liquid with service water 10 °C, 5 °C, 2 °C warmer than the fresh water.

Open the catalog to page 5

(Basis-construction type) - Ball type non-return valve - Anti cavitation protection - Rubber mounting feet or mounting rails Fresh water requirements in [m3/h] dependent on suction pressure, speed and difference in temperature FB = fresh service liquid KB = combined service liquid with service water 10 °C, 5 °C, 2 °C warmer than the fresh water.

Open the catalog to page 6

Construction type M 20 0 with: - Thermostatic service liquid regulation (0 - 30 °C) (High Class-construction type) - Ball type non-return valve - Anti cavitation protection - Rubber mounting feet or mounting rails - Additional service liquid low level monitoring device for conductive liquids Fresh water requirements in [m3/h] dependent on suction pressure, speed and difference in temperature FB = fresh service liquid KB = combined service liquid with service water 10 °C, 5 °C, 2 °C warmer than the fresh water.

Open the catalog to page 7

(High End-construction type) - Ball type non-return valve - Anti cavitation protection - Rubber mounting feet or mounting rails - Additional service liquid low level monitoring device for conductive liquids - Additional standard electric control, steel plate enclosed Fresh water requirements in [m3/h] dependent on suction pressure, speed and difference in temperature FB = fresh service liquid KB = combined service liquid with service water 10 °C, 5 °C, 2 °C warmer than the fresh water.

Open the catalog to page 8

Construction type M 40 0 with: - Plate heat exchanger (screwed) (Low Cost-construction type) - Thermometer between heat exchanger and pump - Ball type non-return valve - Anti cavitation protection - Rubber mounting feet or mounting rails Cooling liquid data for the cold side of the heat exchanger

Open the catalog to page 9

Construction type M 45 0 with: - Plate heat exchanger (screwed) (Basis-construction type) - Thermometer between heat exchanger and pump - Ball type non-return valve - Anti cavitation protection - Rubber mounting feet or mounting rails - Additional service liquid replenishing for conductive liquids, level dependent Cooling liquid data for the cold side of the heat exchanger

Open the catalog to page 10

Construction type M 50 0 with: - Plate heat exchanger (screwed) (High Class-construction type) - Thermometer between heat exchanger and pump - Ball type non-return valve - Anti cavitation protection - Rubber mounting feet or mounting rails - Additional service replenishing for conductive liquids, level dependent - Additional cooling water connection at the heat exchanger, thermostatically regulated (0 - 30 °C) Cooling liquid data for the cold side of the heat exchanger, incl. allowance for pressure loss by installed fittings

Open the catalog to page 11All Flowserve SIHI Pumps catalogs and technical brochures

-

Type NHK and SHK

24 Pages

-

SIHIsanivac 400, 800, 1000

4 Pages

-

PL 325 M

14 Pages

-

PL 91 M, PL 126 M, PL 161 M

16 Pages

-

SIHI ® Gas separation

8 Pages

-

SIHI Liquid Ring Compressors

8 Pages

-

Side Channel Pumps

12 Pages

-

LPG Solutions

12 Pages

-

SIHISuperNova ZHND 032160

14 Pages

-

LEM 26, LEM 51

7 Pages

-

LEM 325, LEM 425

8 Pages

-

Applications and Products

9 Pages

-

Series MFS, 7,200 m³/h

2 Pages

-

Sludge Mixer MFS

2 Pages

-

Mixed Flow, Volute Casing Pump

11 Pages

-

Volute casing pumps

26 Pages

-

Non-clogging Pump

19 Pages

-

Volute casing pump CBT

11 Pages