Website:

Flowserve SIHI Pumps

Website:

Flowserve SIHI Pumps

Group: Flowserve

Catalog excerpts

Liquid ring compressors LOH 05501 VACUUM TECHNOLOGY KPH K 1 133.72105.54.01 E 12/2008 Compression pressure: 0.2 to 2 bar Volume flow: 2.8 to 4.8 m³/h CONSTRUCTION Sterling SIHI liquid ring compressors have a simple but robust construction with the following features and benefits: Capable of handling almost all gases and vapours Near isothermal compression Oil-free, with no internal lubrication Low maintenance and safe operation Low noise and almost vibration free Available in a wide range of materials Broad range of applications Rotating metallic parts are non contacting to minimise wear ATEX compliance The LOH 05501 operates according to side channel principle and therefore the pump has the advantage, besides the abovementioned features to handle large quantities of entrained liquid. Sterling SIHI liquid ring compressors of the range LOH 05501 are two-stage compressors. They can be used as vacuum pumps up to a suction pressure of 80 mbar without any modification. (See the Technical Catalogue – Liquid Ring Vacuum Pumps). APPLICATIONS Pumping and compressing of dry gases and saturated vapours; the compressors can also handle liquids. The compressors are applied in all fields where a compression over pressure of up to 2 bar has to be created by robust compressors and only a small increase in temperature is admissible during compression. Typical application areas include: - the plastics industry, for recovery of process gases as vinyl chloride - the petrochemical industry, for the compression of combustible gases as gasoline vapours or hydrogen - transport of gases in general e.g. to a reactor NOTE By continuously feeding the compressor with a small amount of service liquid (usually water), the heat due to gas/vapour compression is conducted away. This also replenishes the liquid ring and ensures that it does not become saturated with process media. Recharging the pump with service liquid at ambient temperature enables the unit to condense evacuated gases/vapours. It can therefore be used for solvent recovery. The condensed gas and liquid can be separated in a pressure liquid separator. More information is provided in the accessory catalogues. The service liquid can simply be re-circulated. The rotation of the pump is clockwise when viewed from the drive end. GENERAL TECHNICHAL DATA Pump Type Units LOH 05501 Speed rpm 1450 1700 Maximum overpressure on compression bar 2 Maximum permissible pressure difference bar 3 Hydraulic test pressure (overpressure) bar 4 Moment of inertia of rotating parts of pump and water content kg . m² 0.0033 Noise level at 80 mbar suction pressure dB (A) 69 70 Minimum permissible pulley diameter for V belt drive mm 100 112 Maximum gas temperature dry saturated °C °C 200 100 Service liquid: Maximum permissible temperature Maximum viscosity Maximum density °C mm²/s kg/m³ 80 90 1200 Liquid capacity up to middle of shaft litre 1 Maximum flow resistance of the heat exchanger bar 0.2 In selecting a pump, avoid choosing one which is likely to be operating at a combination of its maximum permissible limits e.g. maximum viscosity and maximum permissible pressure difference.

Open the catalog to page 1

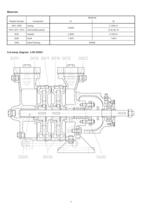

2 Materials Materials Position Number Component 01 32 0001, 0002 Casing 0.6025 2.1050.01 0010, 0011, 0012 Intermediate pieces G Sn Bz 16 0030 Impeller 2.0550 2.1052.01 0200 Shaft 1.4021 1.4401 0400 Gland Packing RAMIE Cut-away diagram LOH 05501

Open the catalog to page 2

3 Performance Characteristics LOH 05501 0 1 2 3 4 5 6 0 0,4 0,8 1,2 1,6 2 2,4 compression over pressure suction volume flow 1450 rpm LOH 05501 1700 rpm bar m³/h 0 0,4 0,8 1,2 0 0,4 0,8 1,2 1,6 2 2,4 compression over pressure power absorption 1450 rpm LOH 05501 1700 rpm bar kW The values indicated for volume flow and power absorption are valid for compression of dry air at 20°C from atmospheric pressure (1013 mbar) to the respective compression pressure with water at 20°C as service liquid. Tolerance of the curve values is 10 %. The compression pressure in bar is indicated as pressure above...

Open the catalog to page 3

4 Dimensions LOH 05501 N 1 = gas inlet G 1 ¼ N 2 = gas outlet G 1 ¼ ue = connection for drain G ¼ um = connection for pressure gauge G ¼ weight: 17 kg The service liquid is fed into the suction line of the pump.

Open the catalog to page 4

5 Make-up liquid consumption in [m³/h] dependent upon compression pressure, speed, drive type and temperature difference Compression pressure in [bar] 1 1.5 2 Type Speed [rpm] KB KB KB Temperature difference [°C] FB Temperature difference [°C] FB Temperature difference [°C] FB 30 20 10 5 30 20 10 5 30 20 10 5 LOH 05501 1450 0.01 0.01 0.03 0.05 0.2 0.01 0.02 0.03 0.06 0.2 1700 0.02 0.02 0.04 0.07 0.02 0.03 0.05 0.08 0.03 0.04 0.06 0.1 0.2 FB = Total service liquid flow rate on once-through system KB = Flow of make-up water when combined with partial recirculation liquid at a temperature of...

Open the catalog to page 5

6 Accessories Recommended Accessory Material Execution LOH 05501 Pressure liquid separator Type / Weight XBd 413 / 28 kg Pressure liquid separator Steel, galvanised SIHI-Part No. on request Bend Steel SIHI-Part No. 35 003 167 Service liquid pipework Steel SIHI-Part No. 35 003 084 Liquid discharge trap Type / Weight XUk 1602 / 11 kg Liquid discharge trap 0.6020+1.4541 SIHI-Part No. Hanging gas line Steel SIHI-Part No. Sterling SIHI – Non Return Ball valve Intermediate flange execution XCk 32 0.6025 + Butadiene rubber 0.6025 + Teflon 1.4408 + Teflon SIHI-Part No. Weight 20 072 744 / 1.2 kg 20...

Open the catalog to page 6All Flowserve SIHI Pumps catalogs and technical brochures

-

Type NHK and SHK

24 Pages

-

SIHIsanivac 400, 800, 1000

4 Pages

-

PL 325 M

14 Pages

-

PL 91 M, PL 126 M, PL 161 M

16 Pages

-

SIHI ® Gas separation

8 Pages

-

SIHI Liquid Ring Compressors

8 Pages

-

Side Channel Pumps

12 Pages

-

LPG Solutions

12 Pages

-

SIHISuperNova ZHND 032160

14 Pages

-

SIHImodular PL 251 M

13 Pages

-

LEM 26, LEM 51

7 Pages

-

LEM 325, LEM 425

8 Pages

-

Applications and Products

9 Pages

-

Series MFS, 7,200 m³/h

2 Pages

-

Sludge Mixer MFS

2 Pages

-

Mixed Flow, Volute Casing Pump

11 Pages

-

Volute casing pumps

26 Pages

-

Non-clogging Pump

19 Pages

-

Volute casing pump CBT

11 Pages