Website:

Flottweg SE

Website:

Flottweg SE

Catalog excerpts

FLOTTWEG AC-SEPARATORS Engineered For Your Success

Open the catalog to page 1

TABLE OF CONTENTS Applications page 02 How the Clarifier Works page 04 How the Purifier Works page 05 The Flottweg Soft Shot® System page 06 Features - the Heart of the Centrifuge page 07 Features - the Drive System page 09 Inert Gas Purging page 11 Experts in Process Engineering page 12 Flottweg Quality and Service page 13 Technical Data page 15 ® = registered trademark in various countries.

Open the catalog to page 2

APPLICATIONS Flottweg AC-Separators for Highly Efficient Clarification and Separation Disc stack centrifuges are high-speed centrifuges for the mechanical separation and clarification of mixtures comprising solids and liquids. Due to their special design, disc stack centrifuges work at a very high rotation speed. As a result, the centrifugal acceleration (g-force) generated by a disc stack centrifuge is extremely powerful. Moreover, the discs included provide a large clarifying area. Thus, it is possible to separate ultrafine solid particles from a liquid and to separate liquid mixtures in...

Open the catalog to page 3

Applications - Beverages • Fats - Oils • Biofuels • Chemistry • Biotechnology • Industry/Mineral Oils

Open the catalog to page 4

HOW THE CLARIFIER WORKS Clarification: Two-Phase Separation (Solid-Liquid) Flottweg Clarifiers separate solids from liquids thus enabling high efficient clarification. The product to be clarified enters the interior of the bowl through a stationary inlet pipe and is gently accelerated by the distributor to the bowl speed. Big solid particles are immediately separated in the centrifugal field. The disc stack in the bowl causes the product stream to be divided up into many thin layers, creating a large clarifying area. The solids are separated from the liquid within the disc stack. The high...

Open the catalog to page 5

HOW THE PURIFIER WORKS Purification: Three-Phase Separation (Liquid-Liquid-Solid) A purifier enables the separation of liquid mixtures with different densities and solids at the same time. In a purifier (three-phase disc stack centrifuge), the product to be separated enters the inside of the bowl through a stationary feed pipe and is gently accelerated by the distributor to the bowl speed. Big solid particles are immediately separated in the centrifugal field. The disc pack in the bowl causes the product stream to be divided up into many thin layers, creating a large clarifying area. The...

Open the catalog to page 6

THE FLOTTWEG THE FLOTTWEG SOFT SHOT® SOFT SHOT® SYSTEM SYSTEM Precise, Silent and Economic Flottweg AC disc stack centrifuges are equipped as a standard with the hydraulic Soft Shot® discharge system. This bowl valve system offers various advantages for the customer: The heart of the Soft Shot® discharge system consists of two bowl valves. The mass of these valves has deliberately been kept low. Thus system inertia is reduced and the system is triggered almost exclusively by the operation water pressure inside the bowl. In contrast to other systems, these valves work at a very high speed....

Open the catalog to page 7

THE FEATURES AT A GLANCE The Heart of the Centrifuge Flottweg Hydrohermetic (optional, e.g. series 420 for the brewing industry) ∙ ormation of a sealing water ring with deaerated water F ∙ Oxygen pick-up is efficiently avoided ∙ No additional CO2 blanketing required ∙ No mechanical wear (compared to mechanical seals) Discharge of the Clarified Liquid Using an Impeller ∙ Clarifier: Discharge of the clarified liquid under pressure; foaming is avoided ∙ Purifier: Discharge of the liquid phases with a double centripetal pump; optional combination of single centripetal pump and free discharge...

Open the catalog to page 8

The Flottweg Soft Shot® System ∙ ccurate partial or total discharges in any combination for A maximum product yield ∙ Material-friendly, silent, nearly inaudible solids discharge ∙ ischarge times can be precisely adjusted, thus highest yields D The Bowl of the Disc Stack Centrifuge ® = registered trademark in various countries. ∙ aintenance friendly thanks to the compact and M robust design ∙ Easy mounting and dismantling; complete modules ∙ educed operating costs due to a reduced number of R components and seals ∙ Quality “Made in Germany” ∙ fficient separation of the solids and maximum...

Open the catalog to page 9

THE FEATURES AT A GLANCE The Drive System The Flottweg Belt Drive ∙ ower is transmitted using a frequency P inverter controlled drive motor via a flat belt ∙ asy and robust construction resulting in E reduced vibrations and smooth running ∙ asy maintenance, low wear, thus high E availability ∙ lexible adaptation to product requirements F thanks to easy and variable adjustment of the bowl speed ∙ educed starting current, operation speed is R quickly achieved ∙ uick and gentle re-acceleration after solids Q dis

Open the catalog to page 10

The Compact Spindle ∙ he spindle unit can be mounted/dismantled as T one complete component. ∙ he bearings are pre-mounted on the spindle. T ∙ asy accessibility, thus easy replacement of the E bushings is possible The Lubrication System of the Disc Stack Centrifuge ∙ ubrication of the spindle ball bearing takes place via a L closed lubrication circuit. ∙ ccurate and complete lubrication at any time, independent A of the rotational speed for a long lifetime of the bowl bearing ∙ igh availability and safety due to automatic control of H lubrication ∙ educed quantity of grease R ∙ utonomous...

Open the catalog to page 11

INERT GAS PURGING If centrifuges are used to process products whose vapors together with oxygen may form a flammable mixture, there is a risk of explosion. Consequently, inert gas purging systems are used to prevent the exit of vapors into the atmosphere (contamination) as well as to avoid the entry of air into the system (explosion). Flottweg offers centrifuges including an inert gas purging concept which is perfectly adapted to the requirements of these applications and in compliance with the highest safety standards.

Open the catalog to page 12

EXPERTS EXPERTS IN PROCESS IN PROCESS ENGINEERING ENGINEERING Every Process Is Different The various parameters have a significant influence on separation efficiency. Knowing these parameters means increasing the efficiency and yield of your separation process. We support our customers along the entire process chain from R&D raw material analyses to approval tests. Flottweg offers all necessary methods for analyzing your products and evaluating new potential. Our worldwide locations and networks ensure support and service for our customers. With the help of our experience and testing...

Open the catalog to page 13All Flottweg SE catalogs and technical brochures

-

Animal by-products

18 Pages

-

Flottweg Academy

10 Pages

-

Wine Production

14 Pages

-

Flottweg Belt presses

11 Pages

-

Flottweg - The Company

36 Pages

-

Flottweg Dough Mixer

4 Pages

-

CE conformity

8 Pages

-

Product brochure Xelletor Series

12 Pages

-

Flottweg Decanter Technology

29 Pages

-

Flottweg Sedicanter®

12 Pages

-

Coffee

19 Pages

-

Flottweg Nozzle Separator

13 Pages

-

Plant Proteins

22 Pages

-

Applicationbrochure Starch

18 Pages

-

Olive Oil

18 Pages

-

Fruit Juice

22 Pages

-

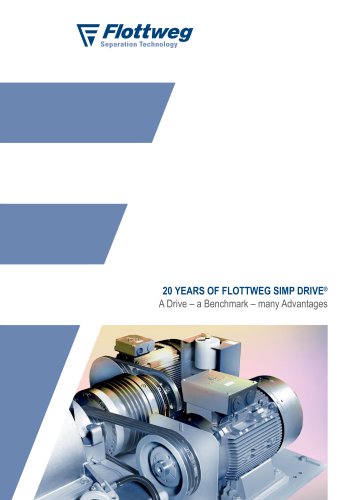

Simp Drive®

4 Pages

-

Flottweg Touch Control

8 Pages

-

Sand and Gravel Wash Water

14 Pages

-

Brewery

20 Pages