Website:

Flottweg SE

Website:

Flottweg SE

Catalog excerpts

SEPARATION TECHNOLOGY FOR THE MEAT INDUSTRY Higher quality, additional yield, reduced disposal costs Engineered For Your Success

Open the catalog to page 1

CONTENTS CONTENTS Page 02 Getting the most out of every process Three-phase process for processing animal byproducts Separation technology for fat recovery Extraction of blood meal Value creation from flotation sludge Flottweg decanters and Tricanters® Flottweg separators Fully automatic value creation Flottweg quality and service ® = registered trademark in different countries. From waste to profit center BACK TO TABLE OF CONTENTS ->

Open the catalog to page 2

SLAUGHTER BYPRODUCTS – FROM WASTE TO PROFIT CENTER In the ever-evolving global meat industry, the application of advanced separation technologies, such as industrial centrifuges, has become essential. This technology plays a key role in overcoming the various challenges facing large slaughterhouses. From regulatory compliance to sustainability considerations, the efficient and effective separation of animal byproducts plays a critical role in economic success. Our state-of-the-art decanter centrifuges and separators offer a comprehensive solution for all meat processing operations that need...

Open the catalog to page 3

Flottweg supports the meat industry in mastering its challenges with these services, among others: ∙ ∙ ∙ ∙ Efficient separation technology for the disposal and recycling of slaughter byproducts Simultaneous extraction of edible fat of high purity and quality Recovery and processing of recyclables from flotation sludge Application-optimized machines in a wide range of configurations up to a fully hygienic design Flottweg is certified to DIN EN ISO 9001:2015 and manufactures its products in compliance with the latest technical standards. Flottweg separation technology is used, among other...

Open the catalog to page 4

SUCCESS IS … MAKING THE BEST OUT OF EVERY PROCESS Flottweg centrifuges are used in various processes for processing offal. Depending on the process, throughputs between 0.5 and 25 t/h (decanter) or 0.5 and 12 t/h (separator) can be processed. Flottweg decanters are used in 2-phase processes, Flottweg Tricanter® in 3-phase processes. Disk dryer Screw press Solids ® = registered trademark in different countries. Flottweg decanter Mill Meal shipment Flottweg separator Storage tank

Open the catalog to page 5

There are basically two different processes: Either a disk dryer (see previous page) or a vacuum dryer (see below) is used. Vacuum dryer (Anderson) Flottweg decanter Solids Screw press Water/solids Mill Flottweg separator Meal shipment Storage tank

Open the catalog to page 6

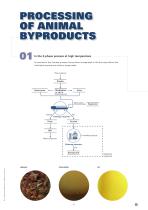

PROCESSING PROCESSING OF OF ANIMAL ANIMAL BYPRODUCTS BYPRODUCTS 01 In the 3-phase process at high temperature In contrast to the 2-phase process, the product is separated in the first step before the individual streams are dried or evaporated. Screw press Stick water Flottweg Tricanter® Mill Water/solids Meal shipment Flottweg separator Fat ® = registered trademark in different countries. Storage tank STICK WATER Separator (optional)

Open the catalog to page 7

The low-temperature process is mainly used in the processing of category 3 material (poultry offal), but also in smaller fat rendering applications. The process engineering schematic is almost identical in all cases. Heating to approx. 90 °C (melting tube) Stick water Mill Water/solids Meal shipment Flottweg separator Storage tank Separator (optional) ® = registered trademark in different countries.

Open the catalog to page 8

PROCESSING PROCESSING OF OF ANIMAL ANIMAL BYPRODUCTS BYPRODUCTS In fat rendering, the byproducts of slaughter that are suitable for further use as food, such as rinds, are processed. There are basically two options for process control when processing these byproducts. Traditionally, after comminuting and heating the product, decanters are used in the first separation step to separate the greaves. In the second work step, the liquid phase is separated from the decanter into the constituents fat, stick water and solids by means of disk stack separators. Usually, the fat phase is clarified...

Open the catalog to page 9

DEWATERING DEWATERING COAGULATED COAGULATED ANIMAL ANIMAL BLOOD BLOOD Animal blood is an important product for the feed industry. In addition, the processing of animal blood into blood meal offers a possibility for further increasing the profitability of slaughterhouses. Flottweg decanters with free overflow are used for dewatering coagulated animal blood. Thanks to the adapted scroll geometry, high cake dryness in the solids discharge can be achieved with excellent separation performance. Blood water Blood meal Flottweg decanter Evaporator or wastewater system High-quality meal for resale...

Open the catalog to page 10

CREATING CREATING VALUE VALUE FROM FROM FLOTATION FLOTATION SLUDGE SLUDGE Flotation is a separation technology that separates particles from the water during wastewater treatment and separates them at the surface by means of gas bubbles — as flotation sludge. Meat/poultry processing companies also use flotation to purify their process water. However, the resulting flotation froth is both difficult-to-dispose residual waste and a potentially valuable mixture of fat and proteins. It is therefore important to combine disposal and value creation. The post-treatment of flotation sludge with a...

Open the catalog to page 11

SPECIAL SPECIAL FEATURES FEATURES OF OF THE THE FLOTTWEG FLOTTWEG DECANTERS DECANTERS AND AND TRICANTERS® TRICANTERS® Flottweg decanter Flottweg decanters are e.g. installed upstream of thermal processes in order to separate liquids from solids (2-phase process). Due to the special design of the Flottweg decanter, the separated solids reach high dry substance levels. This has several positive effects on the overall energy balance of the plant, as centrifugal (mechanical) separation requires less energy for water removal than thermal separation. The steam requirement in downstream drying...

Open the catalog to page 12

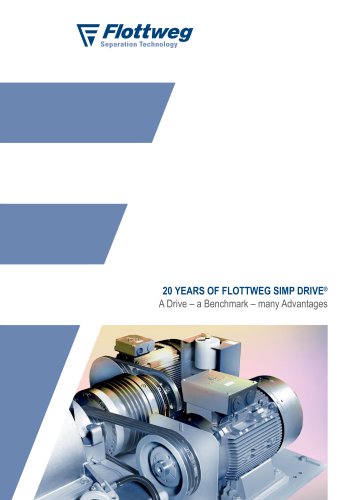

Flottweg Simp Drive® Flottweg impeller (standard for Tricanter®, optional for decanter) The Flottweg Simp Drive® regulates the differential speed based on the scroll torque. As a result, the Flottweg decanter/Tricanter® automatically adapts to varying load conditions and dewaters the supplied product to the respective maximum dry solids content. ∙ Lowest energy requirements due to high efficiency ∙ Pure motorized operation, therefore no oversizing of the drive motors The adjustable impeller allows infinite adjustment of the pond depth during operation and thus fast, precise adaptation to...

Open the catalog to page 13All Flottweg SE catalogs and technical brochures

-

Animal by-products

18 Pages

-

Flottweg Academy

10 Pages

-

Wine Production

14 Pages

-

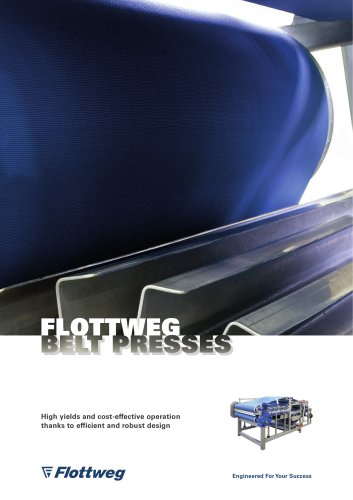

Flottweg Belt presses

11 Pages

-

Flottweg - The Company

36 Pages

-

Flottweg Dough Mixer

4 Pages

-

CE conformity

8 Pages

-

Product brochure Xelletor Series

12 Pages

-

Flottweg Decanter Technology

29 Pages

-

Flottweg Sedicanter®

12 Pages

-

Coffee

19 Pages

-

Separator

17 Pages

-

Flottweg Nozzle Separator

13 Pages

-

Plant Proteins

22 Pages

-

Applicationbrochure Starch

18 Pages

-

Olive Oil

18 Pages

-

Fruit Juice

22 Pages

-

Simp Drive®

4 Pages

-

Flottweg Touch Control

8 Pages

-

Sand and Gravel Wash Water

14 Pages

-

Brewery

20 Pages