Website:

Flottweg SE

Website:

Flottweg SE

Catalog excerpts

SEPARATION TECHNOLOGY FOR THE DAIRY INDUSTRY Highest yield with best quality Engineered For Your Success

Open the catalog to page 1

contents Sustainability and additional earnings for milk processing Page 02 More productivity thanks to Flottweg separation technology Page 03 Flottweg products and processes for the dairy industry Page 04 Recovering valuable ingredients from whey Page 06 Producing alcohol from whey Page 08 Recovering casein Page 09 Extracting calcium phosphate Page 10 Producing lactose Page 12 Processing fermented dairy products Page 14 Processing and recovering milk fat from process streams ... Page 16 ... Pasta filata steeping water Page 17 ... Recovering milk fat Page 18 ... Clarifying cheese wash water...

Open the catalog to page 2

QUALITY & EFFICIENCY FOR A DYNAMIC MARKET The milk processing industry is facing significant challenges: Despite constant demand and rising prices, profitability and competitiveness are negatively affected by higher operating costs for feed and energy. In addition, geopolitical developments and climate change are causing unpredictable production conditions, while strict environmental regulations further complicate operations in many regions. In this context, the pressure on the industry to implement more sustainable production methods is becoming increasingly apparent. These methods, in...

Open the catalog to page 3

Flottweg ensures sustainable, economic processes in milk processing • Conservation of resources: Recovering valuable ingredients from process streams, such as proteins and fats, not only supports the conservation of resources, but also provides an additional source of income. For example, there is a strong demand for whey proteins from cheese production as a basis for meal replacement drinks or food supplements. • Energy savings: Efficient centrifugal separation processes can significantly reduce energy consumption, especially in combination with thermal processes. • Product quality:...

Open the catalog to page 4

SUCCESS IS … LEVERAGING NEW POTENTIAL Flottweg separators and decanters have proven their worth in a variety of applications, especially in the production of raw materials or processing by-products, such as whey, which is one of the greatest sources of high-quality protein. Processing by-products also offers opportunities for the financially lucrative recovery of proteins, fats, or product water. Flottweg separators and decanters are specially developed for the industrial processing of dairy products. These industrial centrifuges are easy to operate and are characterized by their high...

Open the catalog to page 5

Processing by-products with Flottweg separators and decanters Flottweg solutions Cheese, casein production Whey separation Lactose separation Whey fines containing protein Sour milk products Processing and recovering milk fat from process streams Casein separation Separating quark, curd cheese, soft cheese Acid whey Calcium phosphate separation Milk salt Whey cream Cheese Milk fat fines containing protein Alcohol from whey Clarifying cheese wash water and brine

Open the catalog to page 6

RECOVERING RECOVERING VALUVALUABLE ABLE INGREDIENTS INGREDIENTS FROM FROM WHEY WHEY During cheese production, the largest amount of processed milk by far remains behind as whey. But this whey is more than just a by-product as it contains valuable ingredients, including: ∙ ∙ ∙ lactose whey protein minerals The modern dairy industry processes the whey into valuable products – these range from whey drinks and baby food to additives for pharmaceuticals. Any remaining residue, such as broken cheese particles (cheese fines) and residual milk fat, can be separated and recovered from the pure whey...

Open the catalog to page 7

Cheese fines Whey tank Flottweg separator (whey clarification) Dewatered cheese fines Flottweg decanter Clarified whey Flottweg separator (whey skimming) Skimmed whey Whole whey treatment process from the clarification to skimming the whey he low residual fat content in the separated whey increases the product quality of the whey powder and T protein concentrate The “complete” clarification of the whey optimizes the further processing of the separated whey (e.g. increasing the service life of UF plants or evaporator plants) Highest hygiene standards for separators and decanters for high...

Open the catalog to page 8

ALCOHOL ALCOHOL EXTRACTION EXTRACTION FROM FROM WHEY WHEY Another way to create an additional valuable product is to make alcohol from excess cheese whey. The “whey beer” contains a high proportion of fine yeast cells. It is therefore advisable to separate the yeasts from the mash using a Sedicanter® before distillation. This prevents fouling processes in the distillation column, increases the column’s operating life, and reduces the consumption of energy and CIP media. The permeate produced by the ultrafiltration of whey still has a significant lactose content. Instead of throwing this...

Open the catalog to page 9

CASEIN CASEIN RECOVERY RECOVERY To recover casein, the skimmed milk is acidified to its isoelectric point. This can be done using both biological and mineral acids. Alternatively, casein is obtained by enzymatic precipitation (enzymes such as chymosin and rennet). Acidification neutralizes the negatively charged casein micelles, resulting in precipitation of the casein. In a similar way to the rennet precipitation process, the casein is separated from the whey, followed by several washing stages in a decanter. Cheese fines are once again removed from both the whey and wash water via the...

Open the catalog to page 10

EXTRACTION EXTRACTION OF OF CALCIUM CALCIUM PHOSPHATE PHOSPHATE Calcium phosphate, also called milk salt, is a major part of the minerals contained in milk. The extraction of calcium phosphate (DCP process) from whey has become increasingly important in recent years. This is for two reasons: Demineralization not only increases lactose purity but also prevents the formation of deposits downstream. This extends the service life and reduces the CIP cycles. In addition, calcium phosphate is a valuable food supplement that has a wide range of applications in the beverage industry. Calcium...

Open the catalog to page 11

Sweet whey Buffer tank Plate heat exchanger Crystallized milk salts Centrate, lactose process Flottweg decanter Flottweg separator Calcium phosphate (solid) Fine solids Example of the extraction process for calcium phosphate using Flottweg decanter and separator Solids container Efficient separation results High dry matter in solid Hygienic design for a safe end product Optional: Wear protection in hygienic design 11

Open the catalog to page 12All Flottweg SE catalogs and technical brochures

-

Animal by-products

18 Pages

-

Flottweg Academy

10 Pages

-

Wine Production

14 Pages

-

Flottweg Belt presses

11 Pages

-

Flottweg - The Company

36 Pages

-

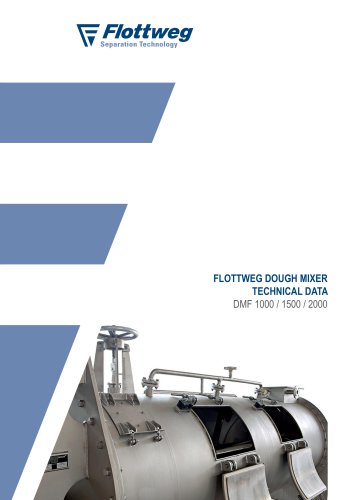

Flottweg Dough Mixer

4 Pages

-

CE conformity

8 Pages

-

Product brochure Xelletor Series

12 Pages

-

Flottweg Decanter Technology

29 Pages

-

Flottweg Sedicanter®

12 Pages

-

Coffee

19 Pages

-

Separator

17 Pages

-

Flottweg Nozzle Separator

13 Pages

-

Plant Proteins

22 Pages

-

Applicationbrochure Starch

18 Pages

-

Olive Oil

18 Pages

-

Fruit Juice

22 Pages

-

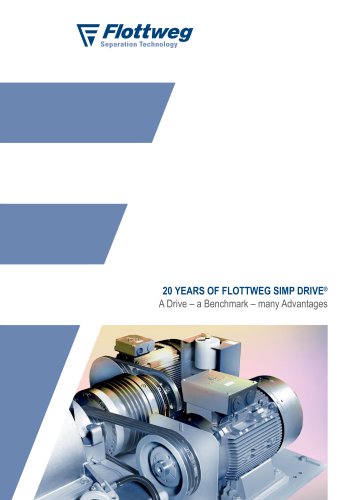

Simp Drive®

4 Pages

-

Flottweg Touch Control

8 Pages

-

Sand and Gravel Wash Water

14 Pages

-

Brewery

20 Pages