Website:

Flottweg SE

Website:

Flottweg SE

Catalog excerpts

SUCCESS IS ... SIGNIFICANTLY REDUCING WATER CONSUMPTION Save More than 90% of Your Process Water when Processing Sand and Gravel Engineered For Your Success

Open the catalog to page 1

TABLE OF TABLE OF CONTENTS CONTENTS The Challenges to be Faced in Sand & Gravel Processing Recycling Washing Water Using Industrial Centrifuges A Complete Solution from One Source Make Your Process Efficient and Environment-Friendly

Open the catalog to page 2

CHALLENGES TO BE FACED IN SAND & GRAVEL PROCESSING Quality requirements for concrete additives are increasing. At the same time, the costs for manufacturers are rising too. In order to meet the strict purity of the washing sand, in many cases, production lines have to be equipped with various processes for classification and washing using additional process technology. This is in direct conflict with the world’s most valuable resource: water. Due to the continuously growing demand for water in agriculture and industry, the availability of water is already restricted in many regions....

Open the catalog to page 3

Flottweg Systems Efficiently dewater sludge generated in wet processing. The volume of waste solids and therefore the disposal costs can be reduced. The recycled water can be re-used for sand processing. More than 90 % of the process water can be recovered, depending on the process.

Open the catalog to page 4

WASH WATER RECYCLING USING INDUSTRIAL CENTRIFUGES Save Process Water and Reduce Costs – Fully Automatically! The use of decanter centrifuges is the optimum solution for water recycling. These industrial centrifuges are laid out to meet the specific requirements for sludge dewatering in the gravel and sand industry. In continuous operation, decanter centrifuges are able to process large quantities of sludge, thus enabling fully automatic operation in parallel to sand processing. The machine separates very fine particles (smaller than 25 µm) and adjusts itself to different quantities and...

Open the catalog to page 5

Sustainable Operation by Water Recycling. The Advantages of the Flottweg Systems for Sludge Dewatering in Sand and Gravel Facilities: ∙ educing the abstraction of groundwater: depending on the process, more than R 90% of the process water can be recycled ∙ o release of untreated process water into the environment: switch from an open N to a closed process-water loop ∙ educing or eliminating settling pond sand lagoons R ∙ ontinuous processing of large sludge quantities: systems for 20 to 400 m³/h C ∙ ully automatic operation with minimum labor utilization F ∙ mall footprint, low costs for...

Open the catalog to page 6

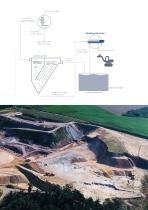

THE PROCESS The wash water to be recycled is conveyed into a lamellar clarifier. From there, the settled sludge is pumped directly into the decanter centrifuge. Due to the high capacity of the centrifuge, normally, intermediate storage is unnecessary. The centrate from the decanter flows continuously back into the process-water tank. The dewatered sludge falls into a bunker. From there, it is brought to stockpiling via a wheel loader or a belt conveyor.

Open the catalog to page 7

used wash water overflow hydro cyclone underflow hydro cyclone Flottweg Decanter separated solids (value product) discharge water phase lamellar clarifier overflow clarifier washing process process-water tank

Open the catalog to page 8

SUCCESS IS ... A COMPLETE SOLUTION FROM ONE SOURCE No matter if you want to expand your existing sand or gravel facility or if you need a turn-key complete solution for water recycling: We would be happy to develop a specific solution together with you that provides your company with the highest benefit. Starting with feasibility studies in our laboratory, via pilot and performance tests in the field under real conditions until the individual engineering solution. Our specialists will be happy to support you! Capacities from 20 to 160 m³/h are available as a standard. Using the PLUS...

Open the catalog to page 9

Separation Unit ∙ lottweg decanter centrifuge in mining configuration F specifically laid out for processing mineral slurries ∙ No cleaning cycle during operation ∙ Continuous and automatic operation (24/7) ∙ No need for consumer utilities such as filter cloths, etc. ∙ pecial wear protection on rotor and scroll. Highly efficient wear S protection made of silicon-carbide elements and bushings for high capacities and a long lifetime of the centrifuge. ∙ he standard equipment includes the Flottweg Simp Drive®, a T drive system resulting in low energy demand and high flexibility under...

Open the catalog to page 10

SUCCESS IS ... AN EFFICIENT AND ENVIRONMENTFRIENDLY PROCESS Beside the machine, the efficiency of the entire process is decisive for achieving the best performance. With the right engineering and suitable solutions, you will get the most out of your process. We take care of the engineering, the layout and the planning of the entire process solution for you. Your advantage: a reliable and efficient process.

Open the catalog to page 11

– Headquarters – Subsidiary – epresentative office R Flottweg is headquartered in Vilsbiburg, Germany, (near Munich) and has branch offices in Cologne and Leipzig as well as subsidiaries in Australia, Brazil, Canada, China, France, Italy, Mexico, Peru, Poland, Russia and the United States plus representatives in nearly all countries worldwide. Check out our website at www.flottweg.com to find your competent contact person.

Open the catalog to page 12

OUR SOLUTIONS AT A GLANCE Flottweg Systems for the Recovery and Processing of Sand and Gravel SCOPE OF SUPPLY Decanter Z6E or Z92 mining version Decanter Z6E or Z92 mining version Decanter Z6E or Z92 mining version Centrifuge Accessories Special tools · Special tools · Fully pre-assembled and wired · On platform System Accessories & Automation Documentation* *One language, more languages on request Control cabinet including activation piloting of the decanter functions Plug & play: · Control cabinet control of the entire system. · All accessories pre-assembled / · Control cabinet, control...

Open the catalog to page 13

Flottweg SE Industriestraße 6-8 84137 Vilsbiburg Germany Tel.: + 49 8741 301-0 Fax: + 49 8741 301-300 Contact form mail@flottweg.com www.flottweg.com

Open the catalog to page 14All Flottweg SE catalogs and technical brochures

-

Animal by-products

18 Pages

-

Flottweg Academy

10 Pages

-

Wine Production

14 Pages

-

Flottweg Belt presses

11 Pages

-

Flottweg - The Company

36 Pages

-

Flottweg Dough Mixer

4 Pages

-

CE conformity

8 Pages

-

Product brochure Xelletor Series

12 Pages

-

Flottweg Decanter Technology

29 Pages

-

Flottweg Sedicanter®

12 Pages

-

Coffee

19 Pages

-

Separator

17 Pages

-

Flottweg Nozzle Separator

13 Pages

-

Plant Proteins

22 Pages

-

Applicationbrochure Starch

18 Pages

-

Olive Oil

18 Pages

-

Fruit Juice

22 Pages

-

Simp Drive®

4 Pages

-

Flottweg Touch Control

8 Pages

-

Brewery

20 Pages