Website:

Flottweg SE

Website:

Flottweg SE

Catalog excerpts

SEPARATION TECHNOLOGY FOR FOOD WASTE, USED FAT AND OILS From waste to valuable raw materials – with lower disposal costs Engineered For Your Success

Open the catalog to page 1

CONTENTS CONTENTS Page 02 Profitable use of Flottweg separation technology Flottweg processes for food waste, used fats and oils Kitchen and food waste as a source of raw materials Used fats and oils in secondary recycling Wastewater removal from fat and oil Flottweg decanter and Tricanters® Flottweg separators Fully automated value creation Flottweg quality and service ® = registered trademark in different countries. Recycling food waste, used fats, and oils BACK TO TABLE OF CONTENTS ->

Open the catalog to page 2

WASTE RECYCLING AT AN INDUSTRIAL LEVEL Not only for environmental reasons but also because of the potential for the creation of value, the recovery of valuable resources from so-called waste is becoming more and more important. In particular, waste containing fats and oils from commercial kitchens, food businesses, slaughterhouses, and private households must be professionally disposed of in many countries around the world. Thus, they become an economic factor that can be recycled. This is where Flottweg technology comes into play: The future of recovering recyclable materials lies with...

Open the catalog to page 3

Flottweg supports you in meeting your challeges and value creation with the following added values, among others: ∙ ew market opportunities are derived from the extraction of recyclable materials N such as fat and protein as a basis for animal feed or for the production of eFuels (HVO) or biodiesel Increased value creation through the recovery of higher-purity fat Reduction of disposal costs through efficient dewatering and thus volume reduction of sludge and residues Flottweg is certified to DIN EN ISO 9001:2015 and manufactures its products in compliance with the latest technical...

Open the catalog to page 4

SUCCESS IS … CONVERTING WASTE INTO PROFITABLE RAW MATERIALS Flottweg offers various separation processes for obtaining purified used fats and oils and for recovering nutrients from food leftovers. For this purpose, Flottweg Tricanter®, decanters, and separators are specially configured for the industrial recovery of valuable nutrients and purified used fats/oils. These industrial centrifuges are easy to operate and are characterized by their high separation efficiency, robustness, and ease of maintenance. This reduces the amortization period and the total cost of ownership. Flottweg...

Open the catalog to page 5

Process overview: Flottweg processes for food waste, used fats, and oils Used fats and oils Wastewater from food production/recycling sed oils and used greases, U e.g. from commercial kitchens, the food industry, or grease separators Kitchen and food waste ∙ ategory 3 material from C commercial kitchens or the food industry Flottweg solution Flottweg solution Flottweg solution Three-phase separation from flotation sludge to fat recovery ecanter and separators for D fat separation and clarification Systems for recycling used cooking fats ystems for separating S food waste Lubricants and oils...

Open the catalog to page 6

KITCHEN KITCHEN AND AND FOOD FOOD WASTE WASTE AS AS A A SOURCE SOURCE OF OF RAW RAW MATERIALS MATERIALS Gastronomy companies and the food industry generate a wide range of waste material: Food waste from food preparation or food production, as well as past-best food or raw materials. This perishable waste must be disposed of quickly in accordance with the relevant legislation. Many waste disposal companies recover valuable raw materials from these animal by-products and food waste, thus opening up an additional source of revenue. For this, the food waste is shredded and hygienized. As a...

Open the catalog to page 7

RECYCLING RECYCLING USED USED FAT FAT AND AND OILS OILS In the food industry and in gastronomy, a considerable amount of used edible oils are discarded as waste. These edible oils may be utilized profitably: The recycled and processed used cooking oils are utilized as raw materials in the production of biodiesel, hydrogenated vegetable oils (HVO), and technical fats. The used oils and used fats that accumulate sometimes contain significant amounts of unwelcome foreign substances. These foreign materials must be separated before further industrial processing in refineries. Plant and animal...

Open the catalog to page 8

® = registered trademark in different countries. PROCESSING PROCESSING OF OF FATTY FATTY WASTEWATER WASTEWATER Numerous fatty side streams can arise during the manufacture and processing of food. These fats and oils are a harmful and expensive contaminant in wastewater. In addition to fat separators in the gastronomy sector, flotation plants are used in industrial operations to treat such wastewater. The resulting flotation froth contains a potentially valuable mixture of fat and protein. It is therefore important to combine disposal and value creation. The post-treatment of flotation...

Open the catalog to page 9

Recovered fats/oils Wastewater stream Heat exchanger Primary flotation plant Flottweg Tricanter® Primary centrifuge Secondary flotation plant Flottweg decanter Secondary centrifuge To the local sewage treatment plant ® = registered trademark in different countries.

Open the catalog to page 10

SPECIAL SPECIAL FEATURES FEATURES OF OF THE THE FLOTTWEG FLOTTWEG DECANTERS DECANTERS AND AND TRICANTERS® TRICANTERS® Flottweg decanter Flottweg decanters are e.g. installed upstream of thermal processes in order to separate liquids from solids (2-phase process). Due to the special design of the Flottweg decanter, the separated solids reach high dry substance levels. This has several positive effects on the overall energy balance of the plant, as centrifugal (mechanical) separation requires less energy for water removal than thermal separation. The steam requirement in downstream drying...

Open the catalog to page 11

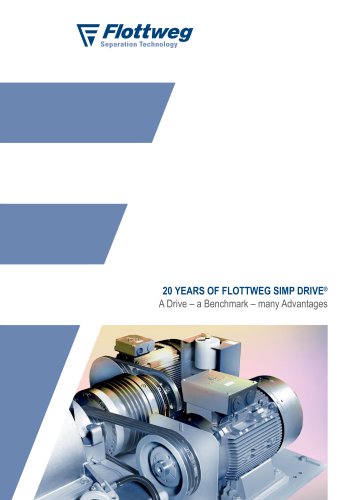

The Flottweg Simp Drive® regulates the differential speed based on the scroll torque. As a result, the Flottweg decanter/Tricanter® automatically adapts to varying load conditions and dewaters the supplied product to the respective maximum dry solids content. ∙ Lowest energy requirements due to high efficiency ∙ Pure motorized operation, therefore no oversizing of the drive motors Hygienic design Flottweg impeller (standard for Tricanter®, optional for decanter) The adjustable impeller allows infinite adjustment of the pond depth during operation and thus fast, precise adaptation to...

Open the catalog to page 12All Flottweg SE catalogs and technical brochures

-

Animal by-products

18 Pages

-

Flottweg Academy

10 Pages

-

Wine Production

14 Pages

-

Flottweg Belt presses

11 Pages

-

Flottweg - The Company

36 Pages

-

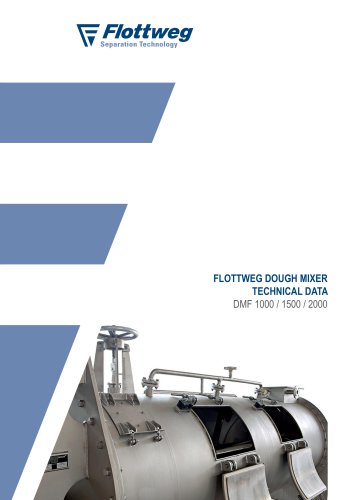

Flottweg Dough Mixer

4 Pages

-

CE conformity

8 Pages

-

Product brochure Xelletor Series

12 Pages

-

Flottweg Decanter Technology

29 Pages

-

Flottweg Sedicanter®

12 Pages

-

Coffee

19 Pages

-

Separator

17 Pages

-

Flottweg Nozzle Separator

13 Pages

-

Plant Proteins

22 Pages

-

Applicationbrochure Starch

18 Pages

-

Olive Oil

18 Pages

-

Fruit Juice

22 Pages

-

Simp Drive®

4 Pages

-

Flottweg Touch Control

8 Pages

-

Sand and Gravel Wash Water

14 Pages

-

Brewery

20 Pages