Website:

Flottweg SE

Website:

Flottweg SE

Catalog excerpts

HIGH QUALITY SEPARATION TECHNOLOGY Flottweg Centrifuges for Olive Oil Production Engineered For Your Success

Open the catalog to page 1

TABLE OF CONTENTS Flottweg Centrifuges for Olive Oil Production page 02 Olive Oil Processing page 03 The Flottweg Decanter/Tricanter® page 04 The Flottweg Disc Stack Centrifuges page 06 Some Unique Features of Flottweg Centrifuges page 08 Features for High Reliability and Availability page 09 Increasing the Oil Yield page 10 Flottweg Quality and Service page 12 Technical Data of Flottweg Disc Stack Centrifuges page 14 Technical Data of Flottweg Decanters C-Series page 15 Technical Data of Flottweg Decanters and Tricanters® Z-Series page 16 ® = registered trademark in various countries.

Open the catalog to page 2

FLOTTWEG CENTRIFUGES FOR OLIVE OIL PRODUCTION Olive Oil Has Been Produced Since Antiquity Ancient olive-oil making was done exclusively by hand. Later on, simple machines such as mechanical presses and pan grinders driven by human or animal power were used. The separation of oil, fruit water, and pulp was done by static settling. At the present time, olive oil is manufactured in a process using modern machinery. In the early 1970s, Flottweg was one of the first companies to introduce decanter centrifuges to the olive oil production process, replacing the existing hydraulic press method. At...

Open the catalog to page 3

Prior to processing, olives are cleaned to remove leaves, bits of branches, stones, soil, and other impurities. Then a mash is produced by crushing the olives and the olive stones. This mash is conveyed to the malaxer or kneading mill. Through malaxing, the oil is released from the oil cells by which it is encapsulated. The malaxing procedure is critical for oil yield and oil quality. The influencing parameters are holding time and temperature. Then the mash is pumped to the Flottweg decanter (2-phase) or Tricanter® (3-phase) for separation. In the Tricanter® (3-phase), the mash is...

Open the catalog to page 4

THE FLOTTWEG DECANTER/TRICANTER® FOR OLIVE OIL EXTRACTION The essential part of the Flottweg decanter/Tricanter® is the rotating part, consisting of a cylindrical/conical bowl with a conveyor scroll inside which rotates at a differential speed. The rotating part is driven by electric motors via belt transmission. Feed enters the bowl through a central feed pipe. Through ports in the scroll body, the feed passes into the bowl where separation by centrifugal force takes place. Solids discharge Liquids discharge by gravity 4 ® = registered trademark in various countries. In a decanter, the...

Open the catalog to page 5

The Flottweg Tricanter® In a Tricanter®, the product is separated into a light liquid phase (oil), a heavy liquid phase (water), and a solid phase (stone debris and pulp). The separated oil is discharged by gravity in both cases, while in addition in a Tricanter®, the separated water phase is discharged by an impeller under pressure or by gravity. The separated solids are conveyed by the scroll to the conical end of the bowl and are discharged. Solids discharge Liquids discharge by gravity 5 ® = registered trademark in various countries. Heavy liquids discharge under pressur

Open the catalog to page 6

FLOTTWEG DISC STACK CENTRIFUGES FOR OPTIMUM OLIVE OIL PURIFICATION Disc stack centrifuges with a self cleaning bowl are used for the separation of oil, water, and solids. Via a fixed feed pipe, the product to be separated enters the inside of the bowl which is rotating at high speed. The product flow is divided into multiple thin layers by the disc stack and a large surface area is created. From the disc stack, the separated liquids flow to the upper part of the bowl where the oil is discharged under pressure via an impeller. The separated water leaves the bowl by gra ity over a ring dam....

Open the catalog to page 7

After the first separation by means of the Flottweg decanter/Tricanter®, the second separation via the Flottweg disc stack centrifuge is critical for oil quality, yield, and overall efficiency. Flottweg AC-series disc stack centrifuges perform both partial and total bowl discharge in any combination. The operation is fully automated via PLC. Using automatic valves for feed and water, the oil content in the bowl is displaced by water prior to bowl discharge. Operation via partial discharge results in virtually no oil loss. Using the total discharge, the bowl stays clean for an extended...

Open the catalog to page 8

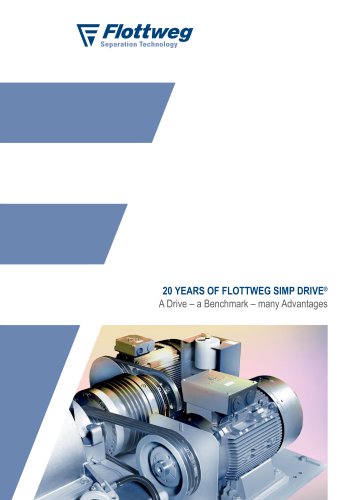

SOME FEATURES THAT MAKE THE FLOTTWEG CENTRIFUGES UNIQUE Optimal performance in terms of oil yield, cake dryness, and power consumption, even under varying olive quality and operation conditions, are achieved by: Gear Drive (VFD) The bowl is driven via a frequency controlled motor enabling a continuously adjustable bowl speed and a fixed gear ratio for differential speed. Flottweg Simp Drive® ® = registered trademark in various countries. In addition to the gear drive, the scroll is driven independently from the bowl by a secondary motor and via a special gear unit. This allows for...

Open the catalog to page 9

FEATURES FOR HIGH FEATURES FOR HIGH RELIABILITY AND RELIABILITY AND AVAILABILITY AVAILABILITY Unique Highly Durable Wear Protection All parts exposed to wear are protected by means of features such as special hard facing, wear bushings, and inserts. Bushings and inserts are easily exchangeable, even under field conditions. Flottweg decanters and Tricanters® can be equipped with a manually operated grease-lubrication device. All bearings are lubricated in a single step. The Flottweg air-oil (droplet) lubrication is available as an option for the Z6E machine. Maintenance Friendly Z4E and Z5E...

Open the catalog to page 10

INCREASING THE OIL YIELD 2nd extraction olive mash Flottweg decanter Flottweg decanter pomace / solids pomace / solids extra virgin olive oil Optional: Repaso-Process (after fermentation) kneading (dilution water) water solids vibrations screen Flottweg Tricanter ® olive oil screw conveyor ® = registered trademark in various countries. Flottweg Sedicanter® vibrations screen

Open the catalog to page 11

Higher Profit Through Second Extraction Flottweg decanters and Tricanters® are optimized for maximum oil yield. Nevertheless, the technical yield in oil during the first extraction is typically in the range between 85 to more than 90 %, due to the olive variety, operation temperature and other process parameters. This is true for 2- as well as 3-phase operation. The pomace after first extraction contains a certain amount of resi ual oil which is worthwhile recovering. d Depending on the efficiency of the first extraction, i.e. oil concentration in the pomace, up to 50 % of the oil can be...

Open the catalog to page 12All Flottweg SE catalogs and technical brochures

-

Animal by-products

18 Pages

-

Flottweg Academy

10 Pages

-

Wine Production

14 Pages

-

Flottweg Belt presses

11 Pages

-

Flottweg - The Company

36 Pages

-

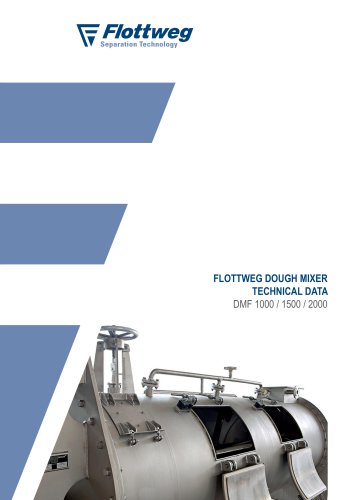

Flottweg Dough Mixer

4 Pages

-

CE conformity

8 Pages

-

Product brochure Xelletor Series

12 Pages

-

Flottweg Decanter Technology

29 Pages

-

Flottweg Sedicanter®

12 Pages

-

Coffee

19 Pages

-

Separator

17 Pages

-

Flottweg Nozzle Separator

13 Pages

-

Plant Proteins

22 Pages

-

Applicationbrochure Starch

18 Pages

-

Fruit Juice

22 Pages

-

Simp Drive®

4 Pages

-

Flottweg Touch Control

8 Pages

-

Sand and Gravel Wash Water

14 Pages

-

Brewery

20 Pages