Website:

Flottweg SE

Website:

Flottweg SE

Catalog excerpts

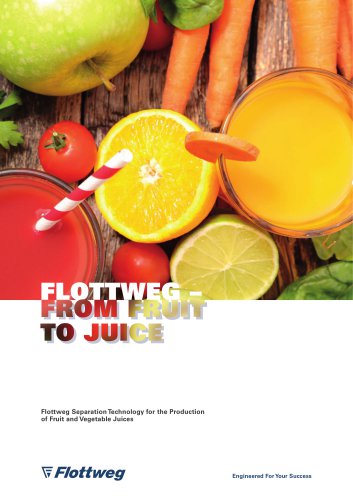

Flottweg Separation Technology for the Production of Fruit and Vegetable Juices Engineered For Your Success

Open the catalog to page 1

TABLE OF CONTENTS Complete Solutions from One Source page 02 From Fruit to Juice page 04 The Optimal Separation Equipment for Each Process page 05 The Flottweg Decanter page 06 The Flottweg Belt Press page 07 The Flottweg Disc Stack Centrifuge page 08 Production of Cloudy Juices page 09 Two-Phase Juice Pressing page 11 Production of Berry Juices page 13 Production of Vegetable Juices page 14 Citrus Fruits - Production of Juices page 15 Citrus Fruits - Production of Essential Oil page 16 Fruit Juice from Puree page 17 Processing Retentates page 18 Flottweg Quality and Service page 19 1 BACK...

Open the catalog to page 2

RELIABLE AND COMPLETE SOLUTIONS FROM ONE SOURCE Flottweg Technology for the Production of Fruit and Vegetable Juices Separation technology plays a prominent role in the production of juices, helping to preserve the precious natural substances of fruits and vegetables. Flottweg offers various systems as well as individual components for the efficient production of highquality fruit and vegetable juices. ∙ rom fruit to juice: complete processing lines, F from the feed of the raw material to juice ∙ ptimal extraction using Flottweg separation O technology assures high yields in the production...

Open the catalog to page 3

Overview of Applications Fruit Juices - Apples and pears - Berries (raspberries, redcurrants etc.) • Cherries - Elderberries • Sallow thorn • Dates • Grapes • Citrus fruits (juices and essential oil) • Tropical fruits (mangos, pineapples etc.) Vegetable Juices • Root vegetables (carrots, beets, celery, onions etc.) • Fruit vegetables (tomatoes, peppers etc.) Special Products • Herbs • Mushrooms • Peas • Soya (okara) • Coffee products • Medicinal plants (nettles, echinacea) • Beverages from grain mas

Open the catalog to page 4

disc stack centrifuge belt press/decanter juice juice for the production of concentrate

Open the catalog to page 5

THE OPTIMAL SEPARATION EQUIPMENT FOR EACH PROCESS The decision of which separation equipment should be used depends basically on the type of fruit or vegetable to be processed. One important selection criterion is the pulping process. Other parameters such as the particle size of the trub to be separated as well as the quantity of solids contained in the mash are also decisive. This diagram shows a simplified overview of applications for Flottweg decanters, disc stack centrifuges and belt presses. solids content of the mash or juice (percent by volume) 10 20 30 40 50 60 70 80 Flottweg disc...

Open the catalog to page 6

THE FLOTTWEG THE FLOTTWEG DECANTER DECANTER Application and Characteristics Decanters are used for the extraction of finely solubilized fruit and vegetable mashes. They excel in high yields and can be used flexibly for different applications. Liquid discharge under pressure Solids discharge Flottweg Decanter – No Standard but an Individual Solution ® = registered trademark in various countries. Continuous operation ∙ Flexibility ∙ Quick and gentle processing ∙ Hygienic due to the closed system Adjustable impeller ∙ High yield also in case of changing feed conditions ∙ Flexible and easy...

Open the catalog to page 7

THE FLOTTWEG THE FLOTTWEG BELT PRESS BELT PRESS Application and Characteristics The Belt Press is used for dewatering products containing a large quantity of solids, e.g. for extracting fruit mashes. The machine excels in high yields and a high dry substance content in the pomace. The special design of the profile rollers and the belt alignment results in high pressure and shear stress, thus assuring a fast and efficient extraction of the product. Filtrate (discharge juice) Solids (pomace) Flottweg Belt Press Continuous operation ∙ Easy handling ∙ Automatically adjusted belt tension ∙ Easy...

Open the catalog to page 8

THE FLOTTWEG DISC THE FLOTTWEG DISC STACK CENTRIFUGE STACK CENTRIFUGE Application and Characteristics Disc stack centrifuges with self-cleaning bowl are used as clarifiers for the separation of fine solids which are not desired in the final product. In case of cloudy juices, trub stability and quality are thus considerably increased. Due to the high g-forces, it is also possible to separate very fine particles. Flottweg disc stack centrifuges can also be used as purifiers (three-phaseseparation) for the production of essential oil. In this process they concentrate and purify an emulsion...

Open the catalog to page 9

PRODUCTION OF PRODUCTION OF CLOUDY JUICES CLOUDY JUICES The Example of Apple Juice The demand for natural and untreated products is continuously increasing. Consumers attach great importance to high quality. Cloudy apple juice, for instance, should have a light color and a clear and stable turbidity. Production should be fast and continuous in order to prevent the product as far as possible from getting a brown color. These requirements can best be met by using a combination consisting of a belt press followed by a disc stack centrifuge. pomace Flottweg belt press Flottweg disc stack...

Open the catalog to page 10

BFRU 1200 BFRU 1500 BFRU 1750 BFRU 2500 Capacity and yields of Flottweg belt presses in the production of cloudy apple juices * Data to be understood as values for cider apples which are immaculate and not overripe Maximum capacity[l/h] * The listed figures are to be understood as guidelines. Actual capacity will depend on the individual characteristics of the feed product.

Open the catalog to page 11

PRODUCTION OF PRODUCTION OF CLOUDY JUICES CLOUDY JUICES Two-Phase Juice Pressing Due to the increasing competition on the worldwide fruit juice market, producers are always interested in obtaining the maximum yield from the raw material. Flottweg decanters can also be used in combination with belt presses for the production of apple juice or juice concentrates. While the Flottweg belt press is the best solution for extraction during the first phase (high capacity and high yields as well as high quality juices), the Flottweg decanters are perfect for postextraction, especially if the pomace...

Open the catalog to page 12

belt elevator condensate dosing belt elevator sorter belt rotating screen apples enzyme dosing extraction tank Flottweg belt press Flottweg belt press repulping screw repulping screw switch cabinet washing water sieve washing water tank juice collecting tank EXAMPLE: TWO-PHASE APPLE JUICE PROCESSING USING A BELT PRESS AND POMACE TREATMENT WITH ENZYMES

Open the catalog to page 13All Flottweg SE catalogs and technical brochures

-

Animal by-products

18 Pages

-

Flottweg Academy

10 Pages

-

Wine Production

14 Pages

-

Flottweg Belt presses

11 Pages

-

Flottweg - The Company

36 Pages

-

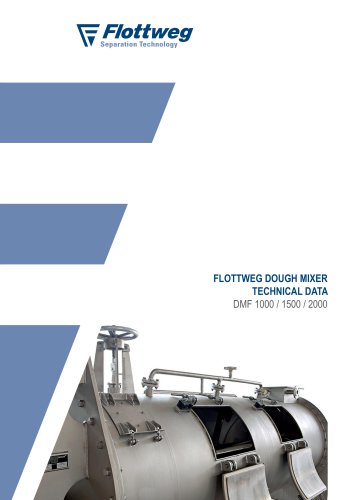

Flottweg Dough Mixer

4 Pages

-

CE conformity

8 Pages

-

Product brochure Xelletor Series

12 Pages

-

Flottweg Decanter Technology

29 Pages

-

Flottweg Sedicanter®

12 Pages

-

Coffee

19 Pages

-

Separator

17 Pages

-

Flottweg Nozzle Separator

13 Pages

-

Plant Proteins

22 Pages

-

Applicationbrochure Starch

18 Pages

-

Olive Oil

18 Pages

-

Simp Drive®

4 Pages

-

Flottweg Touch Control

8 Pages

-

Sand and Gravel Wash Water

14 Pages

-

Brewery

20 Pages