Website:

Flottweg SE

Website:

Flottweg SE

Catalog excerpts

ENGINEERED ... Our passion to design, project and construct ma- chines, thus our passion for technology, has been a part of us since Flottweg’s beginning. Today, with our centrifuges, belt presses and systems, we are continuing what began with aircraft engines and motor bikes. People from all over the world now benefit from our extraordinary knowhow in mechanical solid-liquid separation. Our centrifuges, belt presses and systems are used in many different applications. Many products in daily life would not be available in the required quantity and quality without our cen- ... FOR YOUR...

Open the catalog to page 3

TODAY FLOTTWEG IS ... … a worldwide company with strong values. We follow guidelines which help us to deal with the people around us and those from foreign cultures. These rules are important to us and represent the basis for our actions. We are convinced that it’s not our products that help our company reach the targets we set, but rather the people working at Flottweg - more than 850 employees all over the world are committed to ... customer oriented. We consider our cus- tomers to be partners and we are striving for long-lasting partnerships characterized by openness and sincerity. Our...

Open the catalog to page 5

Gustav Otto, an aviator, constructing engineer and entrepreneur, founds the aircraft factory “Gustav Otto Flugmaschinenwerke” in Munich. In March 1916, this company is integrated into the Bavarian aircraft factory “Bayerische Flugzeugwerke”. This is considered to be the birth of the later Bavarian Engine Company “Bayerische Motorenwerke” (BMW). After World War I, the Munich engine factory “Otto Werke” launches a bike with an auxiliary motor. This is the birth of the brand name Dr. Georg Bruckmayer acquires the rights of the protected name “Flottweg” and founds the engine factory “Flottweg...

Open the catalog to page 6

Due to World War II, the Flottweg Headquarters are relocated to Vilsbiburg and the company produces precision parts for the printing industry. In the 50s, the company starts to develop the first centrifuges as a second business sector. 1956 The first Flottweg Decanter, type Z1, is delivered to BASF AG, Ludwigshafen. From this time onwards, decanter centrifuges become the Flottweg core product. MUNICH 1920 Gustav Otto, who was fascinated by technology son of the inventor of the “Otto-Motore” engines, launches a bike with an auxiliary motor. This bike was called “Flottweg” as the German words...

Open the catalog to page 7

As manufacturer of the first high-speed decanter, Flottweg sets new benchmarks. The Z1L is able to reach accelerations of up to 5400 g. Even very fine solids can be separated successfully. Thanks to this engineering achievement, Flottweg confirms their reputation as technology leader. Flottweg develops and manufactures the three phase decanter. This machine, with the brand name Tricanter®, has been setting benchmarks in different applications. A new generation of belt presses is developed especially for the fruit juice industry. Flottweg presents the high performance decan- ter Z92-4 for...

Open the catalog to page 8

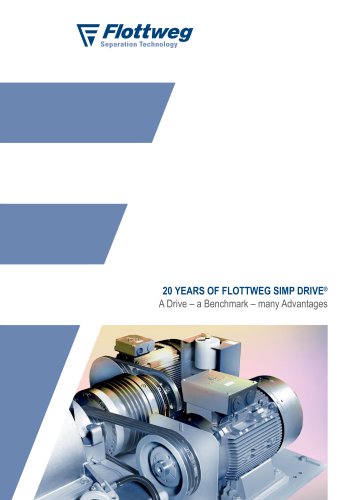

MILESTONES IN SEPARATION TECHNOLOGY ... 1993 A centrifuge concept still unique to this day is … Engineered For Your Success born: The Flottweg Sedicanter®, which combines the advantages of decanters and disc stack centrifuges. The requirements for decanter drives are always increasing. Flottweg develops a milestone in decanter drive technology: The Flottweg Simp Drive®. The system automatically adapts to changing conditions in the feed, differential speed adapts exactly to the required parameters. Due to the high separation efficiency of the drive, energy consumption sinks while dewatering...

Open the catalog to page 9

Flottweg starts with the construction of disc stack centrifuges. A characteristic of the self-cleaning disc stack centrifuges is the silent and efficient Soft Shot® discharge system. In order to be able to serve the Chinese market even better, Flottweg founds its own subsidiary in Shanghai including offices and a workshop. An important year for Flottweg. Peter Bruckmayer, son of Dr. Georg Bruckmayer, releases Flottweg from group affiliation and leads the company to independency. This is the basis for the success in the years to come. 2007 Environmental centrifuge C series. Due to increasing...

Open the catalog to page 10

MILESTONES IN SEPARATION TECHNOLOGY ... high performance centrifuges set new benchmarks in sludge thickening and dewatering while … Engineered For Your Success energy consumption is reduced. 2008 Flottweg founds its own subsidiary in Kentucky, USA, called Flottweg Separation Technology Inc. C-XI series. Flottweg caps it all off: Even more power for the C series. Our engineers once again improve the drive system and the flow streams within the centrifuge. This is a big success. Optimized dewatering performance and highest purity in the centrate are the results. A disc stack centrifuge series...

Open the catalog to page 11

SIX MINUTES … … are all that’s needed to fill an Olympic swim- ming pool with the amount of sludge our ma- chines are processing right now all over the Of course, no one likes swimming in a sludge pool. And that’s exactly why water treatment plants all over the world use our technology – from Atlanta, Berlin, St. Petersburg, Shanghai to Zermatt. Because high-quality drinking water is impossible without efficient waste water treat- Flottweg in the waste water treatment industry • Dewatering and thickening of sewage sludge • Solids separation during drinking water processing • Thickening of...

Open the catalog to page 13

ABSOLUTELY FREE OF PARTICLES … … this is what thick extract has to be in the pro- duction of soluble coffee. Customers expect perfect instant characteristics of soluble coffee powder which means that there should be no insoluble solid particles in their cup after brewing with hot water. To assure this, our clarifier separates all insoluble solids from the extract using enormous acceleration forces of up to 9000 g. Even the finest particles are sepa- rated. This is how we make sure that there will be a perfect instant product in the cup later. That’s how a day should begin … Flottweg in the...

Open the catalog to page 15All Flottweg SE catalogs and technical brochures

-

Animal by-products

18 Pages

-

Flottweg Academy

10 Pages

-

Wine Production

14 Pages

-

Flottweg Belt presses

11 Pages

-

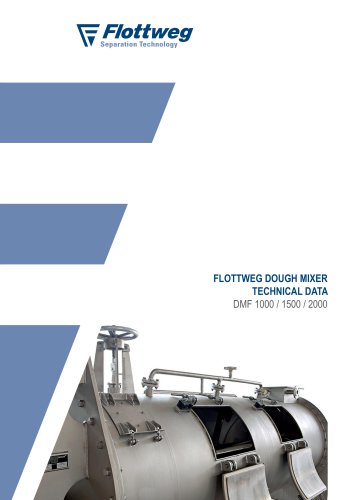

Flottweg Dough Mixer

4 Pages

-

CE conformity

8 Pages

-

Product brochure Xelletor Series

12 Pages

-

Flottweg Decanter Technology

29 Pages

-

Flottweg Sedicanter®

12 Pages

-

Coffee

19 Pages

-

Separator

17 Pages

-

Flottweg Nozzle Separator

13 Pages

-

Plant Proteins

22 Pages

-

Applicationbrochure Starch

18 Pages

-

Olive Oil

18 Pages

-

Fruit Juice

22 Pages

-

Simp Drive®

4 Pages

-

Flottweg Touch Control

8 Pages

-

Sand and Gravel Wash Water

14 Pages

-

Brewery

20 Pages