Website:

Flottweg SE

Website:

Flottweg SE

Catalog excerpts

FLOTTWEG BELT PRESSES High yields and cost-effective operation thanks to efficient and robust design Engineered For Your Success

Open the catalog to page 1

CONTENTS CONTENTS Uses and benefits Design and operating principle Technical data Flottweg quality and service BACK TO TABLE OF CONTENTS ->

Open the catalog to page 2

USES AND BENEFITS Flottweg belt presses – for effective and economical solid/liquid separation in the food industry Belt filter presses are an economically attractive solution for the effective separation of liquid/solid suspensions. By combining dewatering and shearing with special filter belts, Flottweg belt presses can also be used to process products in which the liquid phase is bound in the cell tissue (e.g. organic fruit pulp, plant fibers, etc.). This process increases the separation efficiency, the yield of liquid, and the dry solid content in the pressed-out material. Hence,...

Open the catalog to page 3

Complete machine portfolio With our complete machine portfolio of separators, decanter centrifuges and belt presses, we offer an optimal separation unit for every application or the best combination of various systems for your application. The diagram provides a simplified overview of applications for Flottweg decanter, separators and belt presses. solids content of the mash or juice (percent by volume) 100 mm 10 mm Flottweg decanter Flottweg belt press particle size of the pulp or trub Flottweg Sedicanter® Flottweg disc stack centrifuges Improving recovery and yields in the fruit and...

Open the catalog to page 4

DESIGN DESIGN AND AND OPERATING OPERATING PRINCIPLE PRINCIPLE Especially suitable for use in the food industry The overall build of the Flottweg belt press is engineered for easy cleanability. No additional work platforms are required. All areas are easily accessible and in full view. This allows the operator to monitor the cleaning process at any time. Smooth, large surfaces in the filtrate area and the avoidance of inaccessible corners also promote easy cleaning. The consistent use of stainless steel and food-safe plastics allows the problem-free use of cleaning agents. The relevant...

Open the catalog to page 5

The product is distributed continuously and evenly on the lower belt via the feeding box. The cake height and width can be customized according to the individual product. There are also various feeding systems to ensure optimum product infeed. T he product is pressed onto the wedge zone with the upper belt. A stable product cake is produced by slowly increasing pressure. In the pressing area, cake dewatering is initially carried out via a special profiled roller, which ensures quick liquid drainage to both sides of the press cake. he product is then efficiently dewatered via press rolls...

Open the catalog to page 6

FEATURES AND SPECIFICATIONS Safe production due to stringent hygiene standards Inexpensive to maintain and operate he machine is made entirely of stainless steel T and food-safe plastic. The rollers are held in encapsulated, robust stainless steel bearing brackets. Automatic grease lubrication is available as an option. Continuous belt cleaning with optional additional CIP cleaning ensures a high standard of hygiene. Easy cleaning, operation and maintenance Very good durability and longevity due to the use of high-quality materials Standard drive motors, meaning high availability Regular...

Open the catalog to page 7

TECHNICAL TECHNICAL DATA DATA Technical data for Flottweg belt press 1 Type Length, height, width [mm] depending on the country of installation 1)The figures given are for reference only! Subject to technical changes without notice. 2) The effective throughput rates depend on the product to be processed, the degree of ripeness, and many other parameters. Please do not hesitate to contact our experts via our contact form on flottweg.com with your detailed questions about possible benefits and your process!

Open the catalog to page 8

FLOTTWEG FLOTTWEG QUALITY QUALITY AND AND SERVICE SERVICE Guaranteed Flottweg quality Made in Germany We have a clear vision of quality and make no compromises. Our customers often have to deal with aggressive materials. The components of Flottweg machines that come into direct contact with the medium to be processed are made exclusively from high-quality, rust- and acid-resistant stainless steels. This means higher strength and improved resistance. Ideally equipped, our machines can continuously meet your requirements – in extreme cases 24 hours per day, 7 days per week. Additionally,...

Open the catalog to page 9

Flottweg worldwide Projects in over international subsidiaries service centers – Headquarters – Subsidiary – Representativ

Open the catalog to page 10

Flottweg SE Industriestraße 6-8 84137 Vilsbiburg Germany Tel.: + 49 8741 301-0 Fax: + 49 8741 301-300 Contact form mail@flottweg.com www.flottweg.com

Open the catalog to page 11All Flottweg SE catalogs and technical brochures

-

Animal by-products

18 Pages

-

Flottweg Academy

10 Pages

-

Wine Production

14 Pages

-

Flottweg - The Company

36 Pages

-

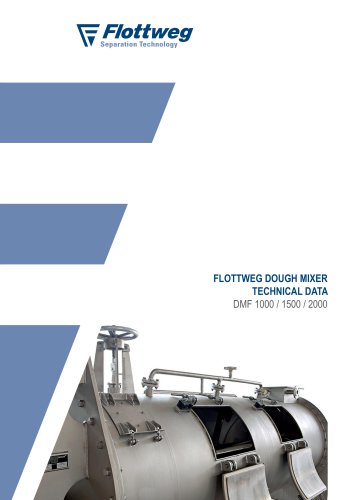

Flottweg Dough Mixer

4 Pages

-

CE conformity

8 Pages

-

Product brochure Xelletor Series

12 Pages

-

Flottweg Decanter Technology

29 Pages

-

Flottweg Sedicanter®

12 Pages

-

Coffee

19 Pages

-

Separator

17 Pages

-

Flottweg Nozzle Separator

13 Pages

-

Plant Proteins

22 Pages

-

Applicationbrochure Starch

18 Pages

-

Olive Oil

18 Pages

-

Fruit Juice

22 Pages

-

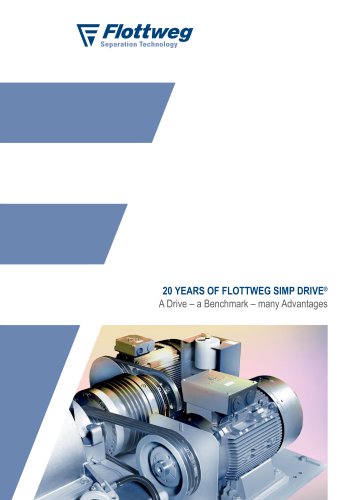

Simp Drive®

4 Pages

-

Flottweg Touch Control

8 Pages

-

Sand and Gravel Wash Water

14 Pages

-

Brewery

20 Pages