Website:

Flottweg SE

Website:

Flottweg SE

Catalog excerpts

SEPARATION TECHNOLOGY PRODUCTION OF INSTANT COFFEE Yield-based coffee extraction plus coffee oil extraction Engineered For Your Success

Open the catalog to page 1

CONTENTS Highest quality and yield for your instant products Page 02 Perfecting proven processes Page 04 Overview of instant coffee production applications Page 05 Clarification of thin extract and thick extract with the Flottweg separator Page 06 Recovery of valuable raw material with the Flottweg decanter Page 08 Extraction of coffee oil with the Flottweg belt press and Flottweg Tricanter® Page 10 Treating and reducing process wastewater Page 13 High yields even with small production volumes Page 14 Optimizing processes and procedures Page 15 Flottweg quality and service Page 16 ® =...

Open the catalog to page 2

HIGHEST QUALITY AND YIELD FOR YOUR INSTANT PRODUCTS Instant coffee has long since evolved from its niche existence as a coffee substitute and has become a lifestyle product. Countless varieties, flavors, and portion sizes make up this highly attractive and still expanding segment of the coffee market, which brings in tens of billions of euros in Europe alone. However, as its popularity increases, so do the requirements: Consumers don’t just want to be surprised with new recipes, they also want to be impressed by their quality. Instant coffee producers are faced with the challenge of meeting...

Open the catalog to page 3

Flottweg is the chosen partner for numerous companies that produce high-quality, flavorful instant coffee on an industrial scale. We support these producers with our separators, decanters, and belt presses. These machines help to increase the quality and purity of the finished (instant) product. In addition, valuable raw materials can be recovered in secondary flows. Flottweg projects stand for absolute customer focus, maximum efficiency, and planning and implementation under the label “Made in Germany” And they create . processes that provide you with a greater overall yield and...

Open the catalog to page 4

SUCCESS IS … DRIVING KNOWN PROCESSES TO PERFECTION The basic principles of producing instant coffee are well-known and proven. Flottweg makes no changes to the basic procedure – we deliver powerful key technologies to support your solid-liquid separation processes. The result: maximum yield, absolute quality, and added value. Our portfolio for instant coffee production ∙ lottweg separators for clarifying thin coffee extract F ∙ Flottweg separators for clarifying thick coffee extract ∙ Flottweg decanters for processing the solids discharged by the separator ∙ Flottweg belt press for...

Open the catalog to page 5

Overview of instant coffee production applications Coffee beans ffe Mixing Roasting Grinding Extraction (percolator batteries) Thin extract Coffee grounds dewatering (recovery of residual extract) Flottweg separator Instantization t t t (freeze drying, spray drying, etc.) p y y g ) Thick extract Flottweg separator Solids Recovered coffee extract Solids Flottweg decanter Flottweg belt press Press water (coffee oil residual extract mixture) Deoiled and clarified press water Recovered coffee oil Flottweg Tricanter® Flottweg separator Deoiled and clarified press water Wastewater treatment Thermal...

Open the catalog to page 6

CLARIFICATION OF CLARIFICATION OF THIN EXTRACT AND THIN EXTRACT AND THICK EXTRACT ... THICK EXTRACT ... Soluble coffee or instant coffee blends are obtained by extracting roasted coffee. After blending, roasting, and milling, the coffee is extracted under pressure. The resulting coffee extract solution contains some insoluble components. By removing these components, consumers can enjoy their coffee without any residue in the cup. Flottweg separators are used at precisely this point in the production process: These separators remove all visible particles, thus improving the quality of the...

Open the catalog to page 7

... WITH THE ... WITH THE FLOTTWEG SEPARATOR FLOTTWEG SEPARATOR The Flottweg Soft Shot® system The insoluble components of coffee extract have a notably viscous, sticky consistency. The quality can vary greatly depending on the blend ratio for the coffee varieties used (proportion of Robusta/Arabica). During separation, these components settle in the solids space of the separator bowl. The challenge here is to safely discharge the separated solids from the bowl during emptying. The solution: To ensure the maximum extract yield and safe operation of the separator, Flottweg separators feature...

Open the catalog to page 8

RECOVERY OF RECOVERY OF VALUABLE RAW VALUABLE RAW MATERIALS ... MATERIALS ... A significant quantity of solids is discharged depending on the type of separator, number of clarifiers used, and processing method. This solid material contains valuable coffee extract. As such, it can be worthwhile to further process the solids-extract mixture. To do so, it is first mixed with hot water. A decanter then efficiently separates the solids from this mixture. The resulting very dry solid (up to 50% dry matter content) can be thermally recycled directly. The extract obtained is then returned to the...

Open the catalog to page 9

... WITH THE ... WITH THE FLOTTWEG DEKANTER FLOTTWEG DEKANTER Flottweg oil-air lubrication system ∙ utstanding recovery rate for coffee extract due to O consistently high dry matter content in separated solids ∙ igh yield even under fluctuating process conditions thanks H to fully automatic adjustment of operating parameters ∙ igh added value with improvement of overall coffee H extract yield ∙ No blocking of decanter bowl Flottweg impeller ∙ Closed discharge of concentrate under pressure, preventing the formation of foam ∙ iquid discharged under pressure, avoiding the L customary need for...

Open the catalog to page 10

COFFEE OIL COFFEE OIL EXTRACTION ... EXTRACTION ... The residue from the percolators or extractors, the so-called coffee grounds, contains different amounts of valuable coffee oil depending on the overall process. This oil can be obtained through a two-stage process using Flottweg machines: First the coffee grounds are pressed, then the press water is separated into its component parts. Extraction residue for press water treatment Coffee oil/water mixture Flottweg belt press Flottweg Tricanter® Flottweg separator Solids Solids Deoiled and clarified press water Thermal recycling of solids

Open the catalog to page 11All Flottweg SE catalogs and technical brochures

-

Animal by-products

18 Pages

-

Flottweg Academy

10 Pages

-

Wine Production

14 Pages

-

Flottweg Belt presses

11 Pages

-

Flottweg - The Company

36 Pages

-

Flottweg Dough Mixer

4 Pages

-

CE conformity

8 Pages

-

Product brochure Xelletor Series

12 Pages

-

Flottweg Decanter Technology

29 Pages

-

Flottweg Sedicanter®

12 Pages

-

Separator

17 Pages

-

Flottweg Nozzle Separator

13 Pages

-

Plant Proteins

22 Pages

-

Applicationbrochure Starch

18 Pages

-

Olive Oil

18 Pages

-

Fruit Juice

22 Pages

-

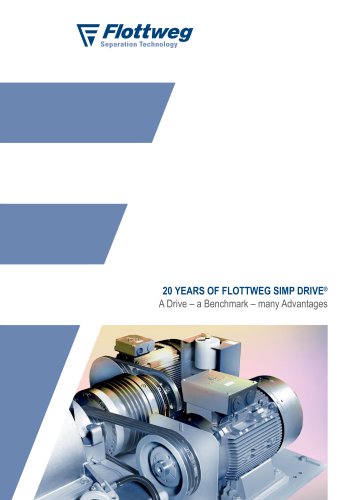

Simp Drive®

4 Pages

-

Flottweg Touch Control

8 Pages

-

Sand and Gravel Wash Water

14 Pages

-

Brewery

20 Pages