Website:

Flottweg SE

Website:

Flottweg SE

Catalog excerpts

SUCCESS IS … HIGH QUALITY, EFFICIENCY, AND SUSTAINABILITY Flottweg Centrifuges for the Recovery of A- and B-Starch, Gluten, and Proteins Engineered For Your Succes

Open the catalog to page 1

TABLE OF CONTENTS Your Strong Technology Partner page 02 The Starch Production Process at a Glance page 03 Turn-Key Systems from a Single Source page 05 The Flottweg Tricanter® page 07 The Flottweg Sedicanter® page 08 The Flottweg Nozzle Separator page 09 The Flottweg Curved Screen BSF page 13 The Flottweg Dough Mixer DMF page 14 Flottweg Quality and Service page 15 ® = registered trademark in various countries.

Open the catalog to page 2

YOUR STRONG TECHNOLOGY PARTNER Sustainable Starch Production The efficient recovery of starch and proteins from renewable raw material coupled with the careful use of resources is becoming ever more challenging for producers. The growing global need and ever-increasing demands of the food industry on raw materials are running up against the increasing scarcity of raw materials and supply bottlenecks. Mechanical solid-liquid separation and industrial centrifuges in particular have been playing a key role in the sustainable production of starch, gluten, and plant-based proteins for many...

Open the catalog to page 3

THE STARCH PRODUCTION PROCESS AT A GLANCE The Process of Extracting Starch and Gluten Flottweg is one of the leading manufacturers of complete process lines for wheat starch production. Thanks to decades of experience, especially in three-phase separation, Flottweg offers innovative process lines which have been optimally adapted to your individual demands. This way, Flottweg customers benefit from optimum yields with minimum expenditure on technical equipment and the lightest possible use of resources. ® = registered trademark in various countries. Possible end products of wheat treatment...

Open the catalog to page 4

process water fresh water vital gluten for dewatering / drying process water to the process water circuit B-starch for further treatment pentosan buffer tank A-starch buffer tank B-starch buffer tank B-starch buffer tank centrifugal sieve Flottweg nozzle separator process water Flottweg Sedicanter® fibres to be dewatered / animal feed to the process water circuit centrifugal sieve Flottweg Decanter / nozzle separator fresh water A-starch for further treatment A-starch buffer tank Flottweg nozzle separator fibres to be dewatered / for drying pentosan for ethanol / animal feed ® = registered...

Open the catalog to page 5

® = registered trademark in various countries. Experience - Long-time Competence and Trust Flottweg has been a supplier for the starch industry all over the world for more than 30 years. The old system of gluten separation in the wheat starch process, called the "Martin Process', has been progressively replaced by the modern three-phase process based on the Tricanter®. Flottweg has accompanied this development from the very beginning and has worked with their customers to optimize the processes. Complete Systems - for a Smooth Operation and High Yields Flottweg is a well-known manufacturer...

Open the catalog to page 6

Our Engineering Excels in the Following Central Points: ∙ lexibility in the selection of the right equipment considering the best product F yields and quality ∙ omplete automation based on the Siemens PLC C ∙ election of components and dimensioning of the system, as well as assembly, S monitoring and commissioning on-site ∙ pproved cooperation with renowned sub-suppliers (Siemens, Danfos, Abb etc.) A ∙ esignated contact person during the whole project life span, from placement D of order until acceptance ∙ Modern engineering tools (3D-layout and pipe pla

Open the catalog to page 7

THE FLOTTWEG THE FLOTTWEG TRICANTER® TRICANTER® Discharge of the heavy liquid phase under pressure Solids discharge Discharge of the light liquid phase by gravity ® = registered trademark in various countries. The Flottweg Tricanter® and Its Benefits ∙ reatest possible purity of the liquids to be separated and optimum G adaptation to changing conditions of the product in the feed by using the adjustable impeller ∙ ther processing steps / separating stages can be eliminated or are O no longer required, offering cost savings for the plant owner ∙ ptimum centrifuge model for any capacity O ∙...

Open the catalog to page 8

THE FLOTTWEG THE FLOTTWEG SEDICANTER® SEDICANTER® Discharge of the liquid phase under pressure Soft and flowable solids like proteins, pentosan, and so on are hard to process using a standard decanter. Only the patented Flottweg Sedicanter® can provide an optimum result. Even under changing feed conditions, it gets the best separation results thanks to its adjustable impeller. Solids discharge wheat production, the Flottweg Sedicanter® can be used the following applications: Separation of fine starch from different process wastewater Clarification and concentration of pentosan Clarification...

Open the catalog to page 9

Flottweg Nozzle Separators in 2- or- 3-Phase Configuration Our Flottweg nozzle separators are available in two basic configurations: a 2-phase configuration to separate solids from liquids and a 3-phase configuration to separate solids from liquids and simultaneously fractionate different particle sizes. In this way, the Flottweg nozzle separators can be adapted to existing production processes. Reduced current during acceleration and quick acceleration to the operation speed Flexible adaptation to the requirements of the product to be processed thanks to a simple and variable control...

Open the catalog to page 10

The Bowl • Bowl with innovative interior design for optimum running smoothness and hygienic requirements • Optionally, the bowl can be equipped with a washing device that is designed as a contact-free and maintenance-free system. • Optionally, it is possible to recycle the concentrate to obtain a higher concentration in order to compensate for product fluctuations and to stabilize the process. • The entire bowl can be mounted or demounted as it is a compact assembly group for easy maintenance. o The Nozzles • Quick and easy replacement of the nozzles makes it possible to optimally adapt the...

Open the catalog to page 11All Flottweg SE catalogs and technical brochures

-

Animal by-products

18 Pages

-

Flottweg Academy

10 Pages

-

Wine Production

14 Pages

-

Flottweg Belt presses

11 Pages

-

Flottweg - The Company

36 Pages

-

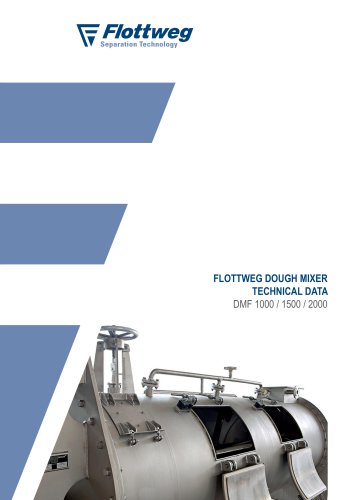

Flottweg Dough Mixer

4 Pages

-

CE conformity

8 Pages

-

Product brochure Xelletor Series

12 Pages

-

Flottweg Decanter Technology

29 Pages

-

Flottweg Sedicanter®

12 Pages

-

Coffee

19 Pages

-

Separator

17 Pages

-

Flottweg Nozzle Separator

13 Pages

-

Plant Proteins

22 Pages

-

Olive Oil

18 Pages

-

Fruit Juice

22 Pages

-

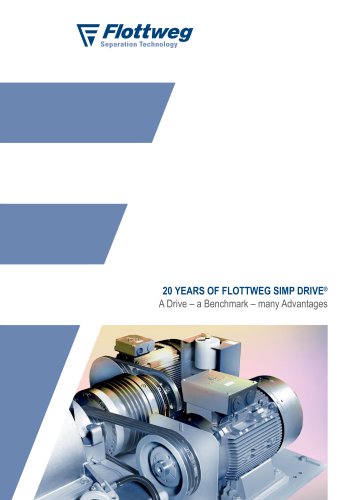

Simp Drive®

4 Pages

-

Flottweg Touch Control

8 Pages

-

Sand and Gravel Wash Water

14 Pages

-

Brewery

20 Pages