Website:

FlexQube

Website:

FlexQube

Catalog excerpts

MATERIAL HANDLING ROBUST, MODULAR

Open the catalog to page 1

“As a kid, did you love to play with Lego® or Meccano®? As a professional, do you love efficient intralogistics? Then this is what you’re looking for.” Per Augustsson Inventor, co-founder and CTO of Flex

Open the catalog to page 2

THE FLEXQUBE® CONCEPT Today's challenges 4 Basics of FlexQube carts 10 FlexQube standard module 12 Co-operation with STILL Liftrunner® 22 FLEXQUBE® PRODUCT GUIDE Pallet tugger carts 26 Carts for STILL Liftrunner® 28 Pallet push carts 29 Flat shelf carts 30 Flow shelf carts 31 Carts with extendable shelves 32 Mother-daughter cart systems 31 Roller transfer carts 35 Order picker carts 40 Fabric compartment carts 42 THE WORLD OF FLEXQUBE® Contact information 62

Open the catalog to page 3

MASS CUSTOMIZATION AND CONSTANT CHANGE –THE TWO TRENDS THAT SET THE TONE 4 LET US KEEP YOU UPDATED AT WWW.FLEXQUBE.COM/NEWS

Open the catalog to page 4

With FlexQube, imagination is the only limit. Let your creative business spirit go live! Show us your challenge and we'll show you the solution. The manufacturing and distribution industry is facing one of the largest challenges in history. The mass customization trend is accelerating, and consumers are more than ever expecting personalized products and a constant flow of updates. For the manufacturers, this means increasing numbers of products, shorter production series and, not least, an increasing number of parts. Each product requires its own unique parts, delivered to a specific...

Open the catalog to page 5

INCREASED NUMBER OF ARTICLES FREQUENT TRANSPORTS 1 SEPARATED FORKLIFT ZONES THE FLEXQUBE® OFFER Supplying parts from the warehouse to the production areas in an efficient and safe way is a key challenge for every factory today. Thanks to our flexible yet sturdy components, you can use the FlexQube concept to design applications for the complete plant –lightweight applications, heavy-duty applications, stationary racks, moving carts, and so on. 6 EVERY FLEXQUBE ® SOLUTION CAN BE TOTALLY CUSTOMIZED TO SUIT YOUR NEEDS ROBUST CART

Open the catalog to page 6

CONSTANT CHANGE ADAPTED MATERIAL PRESENTATION 2 FLEXIBLE MATERIAL FAÇADE 7 FLEXIBLE ASSEMBLY LINES INTEGRATION WITH NEW TECHNOLOGY MODULAR SYSTEM GREAT ERGONOMICS ADAPTABLE CARTS GLOBAL PRESENCE 7 EVERY FLEXQUBE ® SOLUTION CAN BE TOTALLY CUSTOMIZED TO SUIT YO

Open the catalog to page 7

PEG BOARD CART These carts allow the Proterra operators to actually assemble the bus from the inside, without having to leave the bus. This is a huge improvement in assembly efficiency for Proterra. ANGLED WORK TABLES These work tables are custom designed alongside the engineers at Proterra to aid in the development of material transportation. EVERY FLEXQUBE® SOLUTION CAN BE TOTALL'

Open the catalog to page 8

WINDSHIELD CART This cart is specifically designed with ergonomics in mind, to make it easier for the operator to move large and odd-sized items such as windshields. TYRE KIT-CART These carts are custom-built to enable pushing the cart up to the assembly station and roll the tyre straight off the cart and into the assembly area. UTION CAN BE TOTALLY CUSTO D ■ TO SUIT YOUR NEEDS

Open the catalog to page 9

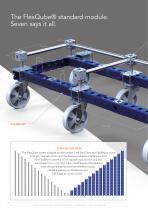

The FlexQube® standard module. Seven says it all. 7CM DESIGN BASE The FlexQube system is based on the number 7. All FlexTubes and FlexBeams come in length intervals of 7cm and the distance between interfaces is 7cm. Two FlexBeams create a 7×7cm square cross-section and two FlexQubes form a 7×7×7cm cube. FlexPlates and FlexQubes have the same interface and are therefore easily placed anywhere on FlexBeams and FlexTubes to connect them. 10 EVERY FLEXQUBE ® SOLUTION CAN BE TOTALLY CUSTOMIZED TO SUIT YOUR

Open the catalog to page 10

The standard interface and intervals enable FlexQube to have a very efficient and quick design process, where the lead time from customer requirements to design draft can be FLEXQUBE® cut down significantly. STANDARD FASTENERS - NO SPECIAL TOOLS Due to the homogeneous interface, virtually all connections are made using M6 bolts. The FlexBeam also has an M10-hole for heavy-duty connections and thus M10-bolts and nuts can also be used. This means that all connections can be done with a small number of tools. EVERY FLEXQUBE® SOLUTION CAN BE TOTALLY CUSTOMIZED TO SUIT YOUR NEEDS

Open the catalog to page 11

The basics of FlexQube® carts. FlexQube carts can easily be optimized for the transportation of material and components, or for both the transportation and presentation of the material to the operator at the assembly station. BASIC DESIGN The basic design of a FlexQube cart is a bottom frame with a top structure attached to it. The bottom frame is usually equipped with a set of casters and swivels, handlebars and tow bars, and a brake. Each of these attachments are specified and located optimally to suit the actual application and the ergonomic requirements. The dimensions of the bottom...

Open the catalog to page 12

"FLEXQUBE HAS INCREASED OUR PRODUCTIVITY BY 25 PERCENT Industrial carts with built-in flexibility for future changes in component design and manufacturing mix. CUSTOMIZATION The top structure is optimized for the type of cargo to be carried. It can be anything from a solid steel flatbed for heavy pallets, to an advanced rack for a model-specific assembly kit. Check out our Solutions Library™ for inspiration! www.flexqube.com/sl EVERY FLEXQUBE® SOLUTION CAN BE TOTALLY CUSTOMIZED TO SUIT YOUR NEEDS

Open the catalog to page 13

The functional features of FlexQube® carts. TURNING RADIUS PUSH FORCE TRACKING PATH START FORCE 14 EVERY FLEXQUBE ® SOLUTION CAN BE TOTALLY CUSTOMIZED TO SUIT YOUR NEEDS

Open the catalog to page 14

Fixed casters and a unique towbar mean FlexQube carts come with built-in ergonomics. They are also easily connected for full flexibility in delivery and pickup. SPEED LIMIT WEIGHT i TRAIN SETUP NOISE LEVEL EVERY FLEXQUBE® SOLUTION CAN BE TOTALLY CUSTOMIZED TO SUIT YOUR NEEDS

Open the catalog to page 15

FLEXQUBE® CUSTOMER CASE ELECTRIC BUS MANUFACTURING AT PROTERRA “SEAMLESS AND TRANSPARENT PROCESS FROM DESIGN TO IMPLEMENTATION” Lalit Savalia, Proterra “During an intense period of time in the spring of 2017, FlexQube developed 25 different applications.” Proterra is the largest manufacturer of electric buses in the U.S. When they built two new plants, Lalit Savalia was in charge of the production technology, with a focus on material handling. He got an idea. He had been following FlexQube for quite some time and saw the point of leaving unflexible, welded carts behind. Instead, he now saw...

Open the catalog to page 16