Catalog excerpts

System information System overview FlexLink's newly developed stainless steel conveyor is designed to fit into demanding primary and secondary packaging applications. It addresses important aspects of today's packing processes, such as being easy to clean, smooth handling of products, safe for operators, robust design, long life, and easy to maintain with a low cost of ownership. The modularized and standardized design ensures fast set up, and facilitates rapid future extensions and changes. Separation of larger surfaces To simplify cleaning and to ensure consistent results, larger surfaces have been separated to improve access between them for cleaning and inspection of results. This separation also improves drainage and speeds up the drying process after cleaning. Also, the bearings are separated 25 mm from the framework with spacers to prevent contamination. System information

Open the catalog to page 1

Small contact surfaces No flat surfaces for better drainage To make the cleaning process faster and consistent, the small contact surfaces within the frame have been designed in order to eliminate hard-to-reach areas. In wash-down environments, it is important to have proper drainage of water and other liquids. The WLX design has been optimized in this regard by selecting different manufacturing processes to create shapes that enable efficient drainage. This will also have an important impact on its ability to be cleaned in dry environments in both primary and secondary packaging lines. No...

Open the catalog to page 2

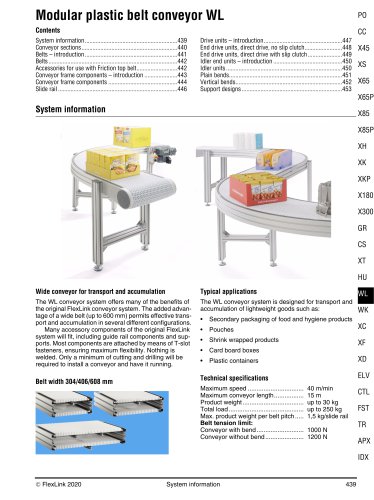

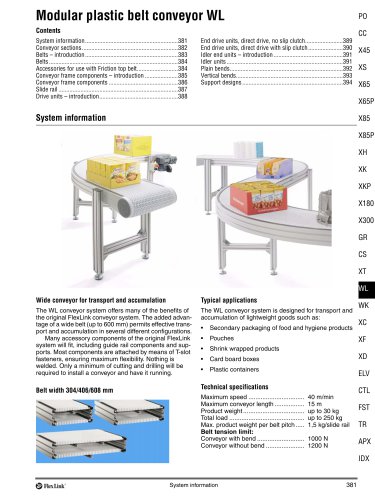

Conveyor sections WL The modular plastic belt conveyor in five widths – 222, 273, 374, 526 and 678 mm – can be built as straight sections 273X or in S, U or L-shape with 30, 45, 60, 90° (180° only for 222 and 273) horizontal bend, or combinations thereof. WL Vertical bends are available in 5° (3° only for 222 and 273) positive or negative. 374X WL 526X Kit for conveyor beam end, always included in: - End drive units - Idler end units - Plain bends - Vertical bends Conveyor sections

Open the catalog to page 3

Modular Belts - Introduction Outer slide rail Slide rail Belt guide Lower cross bar Modular belt, Radius flush grid, curve-running The belt consists of plastic hinged links connected by plastic rods. The wide belts are woven together by links that are 102 mm, 124 mm, and 180 mm wide. The assembled belt forms a wide, flat, and tight conveyor surface. Five standard widths of belt can be delivered: 152 mm, 203 mm, 304 mm, 456 mm, and 608 mm. Standard belt colour is white but blue belts can also be ordered. Belts with polyamide pins are available for dry or semiwet applications. In constant wet...

Open the catalog to page 4

Modular belts Radius flush grid belt, Wet Radius flush grid belt, Dry Plain belt Belt material Acetal (POM) Pin material Acetal (POM), white Length 1 m 152 mm wide, White 152 mm wide, Blue Plain belt Belt material Acetal (POM) Pin material Polyamide (PA), brown Length 1 m 152 mm wide, White 152 mm wide, Blue Radius flush grid belt, Dry (Spare part only Available as request for quote item) Belt tensioner tool for radius flush grid Belt tensioner tool Radius flush grid belt, Wet (Spare part only Available as request for quote item) Plain belt Belt material Acetal (POM) Pin material Polyamide...

Open the catalog to page 5

Conveyor Beams - Introduction when connecting to an End drive unit is 844 mm. This ensures a sufficient amount of return belt tension directly after the drive sprocket to avoid slack close to the sprocket wheel. The return belt hanging between the first two belt guides provides this belt tension (called back tension). For more information see WLX Engineering guidelines. Connecting brackets have to be ordered separately when joining End drives, idler ends, conveyor beams, etc. When joining two conveyor beams, a beam spacer kit must be ordered separately. Conveyor dimensions Conveyor frame...

Open the catalog to page 6

Technical specifications Minimum permissible conveyor beam length to be connected: PO X70X X85X X180X WLCBX 3A Standard length 3000 mm 6 mm space, easy to clean WL 374X 6 mm space, easy to clean WLCBX LA L = 1700 mm 6 mm space, easy to clean Top belt travel direction Conveyor Beams - Introduction

Open the catalog to page 7

Conveyor frame components Beam spacer Kit for WL222 Conveyor beam, Easy Clean Conveyor beam, WL222X Length 3 m (3000 ±1,2 mm) WLCBX 3A222 Length to order (142- 2999 mm) WLCBX LA222 Weight, 1 m, incl. belt: 14 kg/m Recommended Torx tool for fasten spacer Size T30 Torx Connecting Bracket For beam Including 4 pcs M10 screws Beam support brackets 56 A Beam support bracket (A) Including 6 pcs M10 screws Beam support bracket (B) Including 2 pcs M10 screws and 2 pcs spacer WLRDX M10X25 Beam support bracket (C) Adjustable ±40° Conveyor frame components

Open the catalog to page 8

Slide rail Slide rail Slide rail, length 3 m Slide rail (A) Outer slide rail (B) Connecting Strip x4 x4 PO Connecting strip kit Contains 10 pcs. Drill fixture for connecting strip Contains drill fixtures for both WLCRX 3 and WLCRX 3B Slide rail

Open the catalog to page 9

Belt tensioner unit A belt tensioner unit should always be placed near the End drive unit and its use is recommended: - for long conveyors >20 meters - for long conveyors >15 m and a speed of >30 m/min - for conveyors with frequent starts/stops, especially if the load is high - if an End drive unit needs to be placed close to a plain bend - if an End drive unit needs to be placed on the lower part next to a conveyor slope section Direct drive, no slip clutch - for short conveyors where the belt slack length is insufficient to lift the belt for cleaning Drive unit types Drive unit types A...

Open the catalog to page 10

Drive units – configuration strings Below are two examples of text strings obtained from the configurator with explanations. Drive unit with fixed speed motor Drive unit with variable speed motor Item no - Drive type WLEBX: TF: Thermal protection type TF TH: Thermal protection type TH (position is omitted for variable speed motors) No: No hybrid cable C: Hybrid cable included in SEW Movimot (position is omitted for fixed speed motors) B – Motor position K – Fieldbus No: No fieldbus P: Profibus fieldbus, maintenance switch D: DeviceNet fieldbus, maintenance switch (position is omitted for...

Open the catalog to page 11All FlexLink catalogs and technical brochures

-

Food and dairy

8 Pages

-

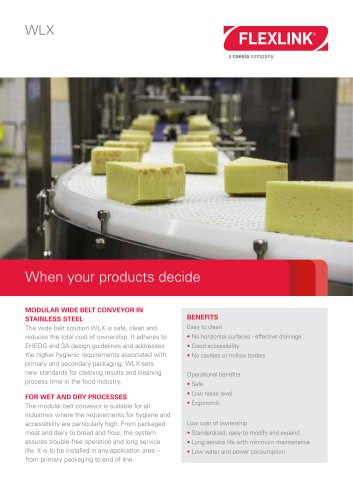

WLX

2 Pages

-

Enclosures and safety guards

158 Pages

-

PRODUCTION FLOW SOLUTIONS

8 Pages

-

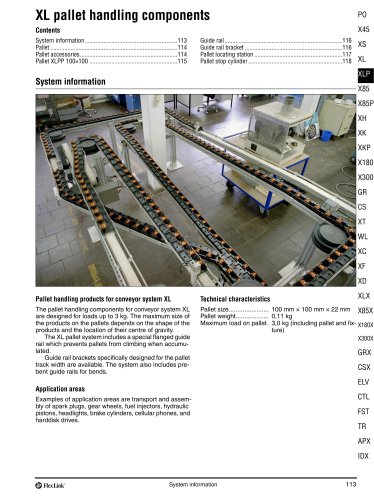

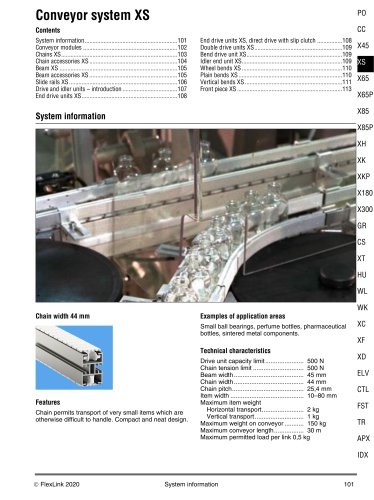

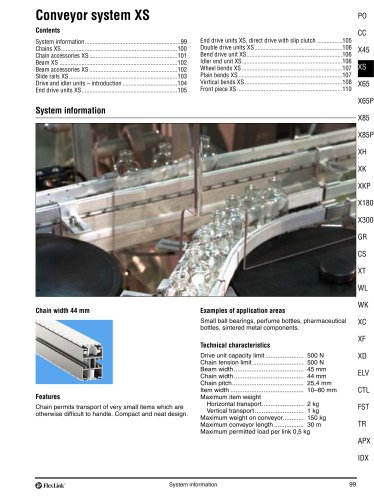

Conveyor system XS

14 Pages

-

Elevator

4 Pages

-

Modular plastic belt conveyor WK

14 Pages

-

Modular plastic belt conveyor WL

16 Pages

-

Conveyor system X65

32 Pages

-

Product overview

498 Pages

-

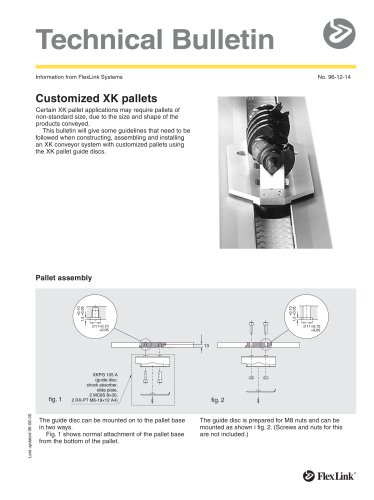

Customized XK pallets

2 Pages

-

GENIUS PCB HANDLING SYSTEM

66 Pages

-

Product Catalogue

160 Pages

-

Configurable Components

20 Pages

-

SMART PCB handling system

12 Pages

-

GENIUS line

8 Pages

-

SMART line

4 Pages

-

Pallet system XTH

4 Pages

-

Conveyor system WL374X

16 Pages

-

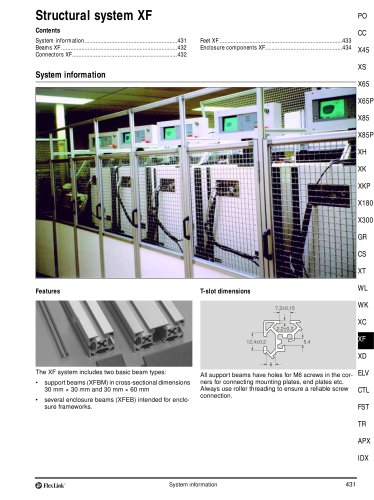

Structural system XF

8 Pages

-

Structural system XD

4 Pages

-

Spiral elevator

2 Pages

-

Pallet system XK

16 Pages

-

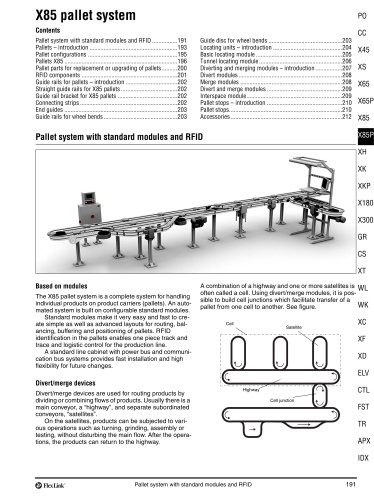

Pallet system X85

22 Pages

-

Conveyor system WL526X

16 Pages

-

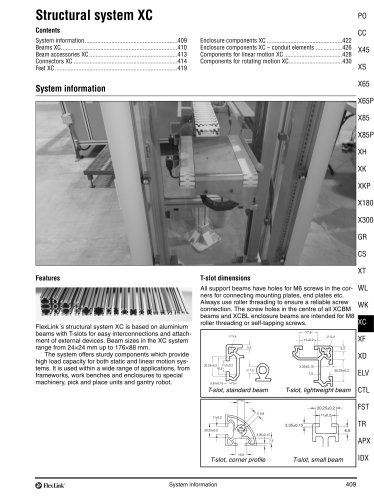

Structural system XC

22 Pages

-

Conveyor system XLX

8 Pages

-

Pallet system XT

50 Pages

-

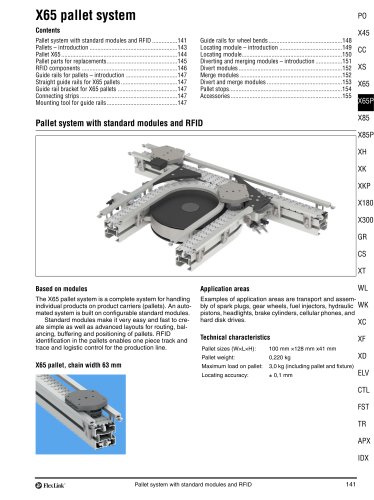

Pallet system X65

16 Pages

-

Conveyor system WL678X

16 Pages

-

Conveyor system X300X

14 Pages

-

Conveyor system X180X

14 Pages

-

Conveyor system X85X and X85Y

18 Pages

-

Profile system MS+

320 Pages

-

Product overview

24 Pages

-

Conveyor system WK

12 Pages

-

Conveyor system XW

20 Pages

-

Conveyor System WL

16 Pages

-

Conveyor System X300

10 Pages

-

Conveyor System X180

10 Pages

-

Conveyor System XK

20 Pages

-

Conveyor System XH

20 Pages

-

Conveyor System X85

34 Pages

-

Conveyor System X65

30 Pages

-

Conveyor System XS

12 Pages

-

Conveyor System X45

48 Pages

Archived catalogs

-

Conveyor System XL

28 Pages