Catalog excerpts

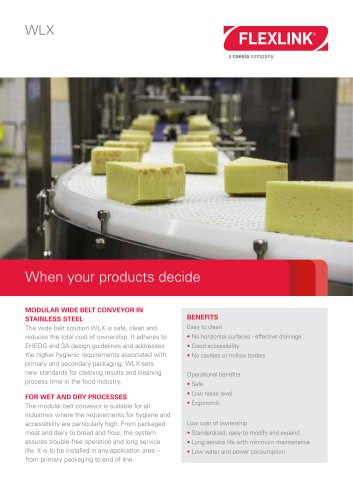

When your products decide MODULAR WIDE BELT CONVEYOR IN STAINLESS STEEL The wide belt solution WLX is safe, clean and reduces the total cost of ownership. It adheres to EHEDG and 3A design guidelines and addresses the higher hygienic requirements associated with primary and secondary packaging. WLX sets new standards for cleaning results and cleaning process time in the food industry. FOR WET AND DRY PROCESSES The modular belt conveyor is suitable for all industries where the requirements for hygiene and accessibility are particularly high. From packaged meat and dairy to bread and flour, the system assures trouble-free operation and long service life. It is to be installed in any application area – from primary packaging to end of line. BENEFITS Easy to clean • No horizontal surfaces - effective drainage • Good accessibility • No cavities or hollow bodies Operational benefits • Safe • Low noise level • Ergonomic Low cost of ownership • Standardized, easy to modify and expand • Long service life with minimum maintenance • Low water and

Open the catalog to page 1

When your products decide A clean case The cleaning process for WLX is quick and easy, setting new standards for results and available process time. The design facilitates simple cleaning procedures and ensures a consistent result. The hygienic design is fit for purpose with rounded corners and flat surfaces. Hollow bodies and crevices, where pathogens and contaminants tend to get trapped, are eliminated. In addition, less water and detergents are needed, thus lowering costs and boosting sustainability. Let´s play it safe Operator safety is prioritized by eliminating pinch points and sharp...

Open the catalog to page 2All FlexLink catalogs and technical brochures

-

WLX222

16 Pages

-

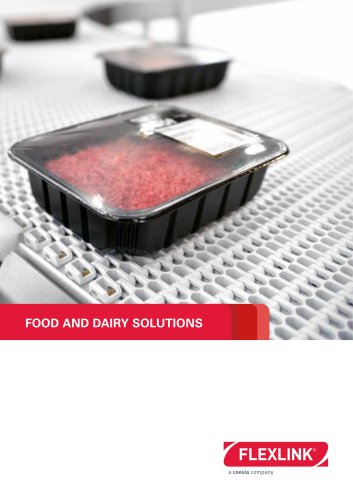

Food and dairy

8 Pages

-

Enclosures and safety guards

158 Pages

-

PRODUCTION FLOW SOLUTIONS

8 Pages

-

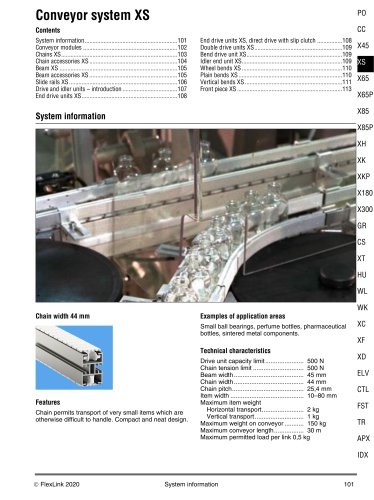

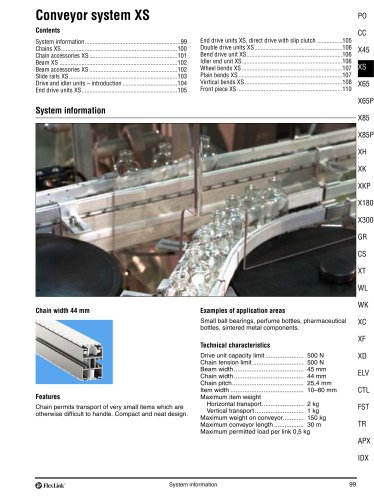

Conveyor system XS

14 Pages

-

Elevator

4 Pages

-

Modular plastic belt conveyor WK

14 Pages

-

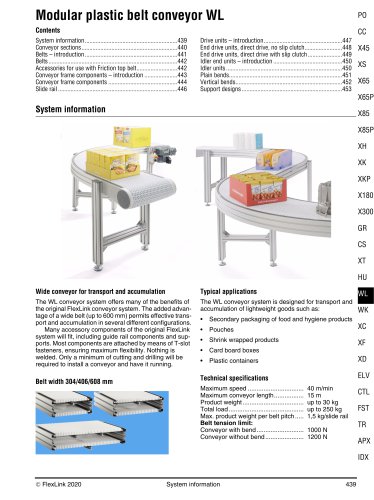

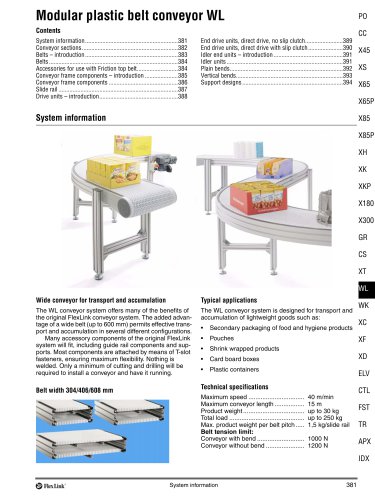

Modular plastic belt conveyor WL

16 Pages

-

Conveyor system X65

32 Pages

-

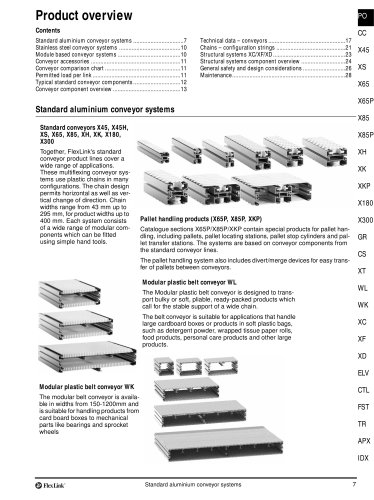

Product overview

498 Pages

-

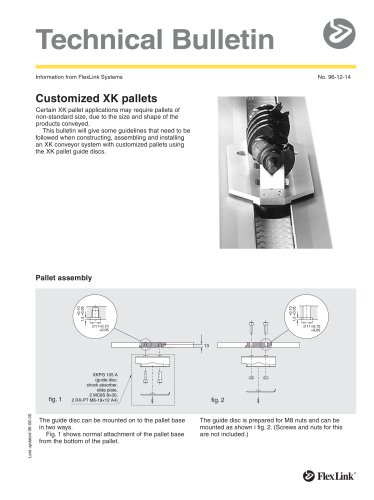

Customized XK pallets

2 Pages

-

GENIUS PCB HANDLING SYSTEM

66 Pages

-

Product Catalogue

160 Pages

-

Configurable Components

20 Pages

-

SMART PCB handling system

12 Pages

-

GENIUS line

8 Pages

-

SMART line

4 Pages

-

Pallet system XTH

4 Pages

-

Conveyor system WL374X

16 Pages

-

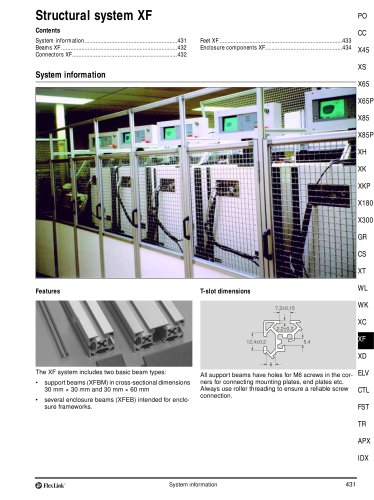

Structural system XF

8 Pages

-

Structural system XD

4 Pages

-

Spiral elevator

2 Pages

-

Pallet system XK

16 Pages

-

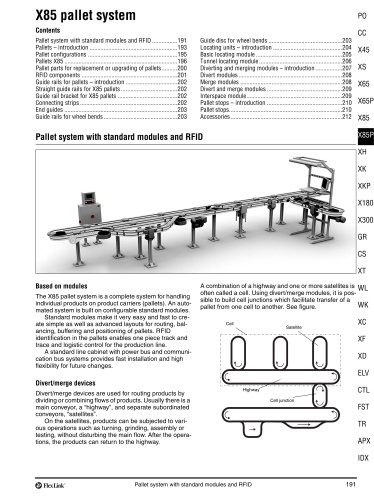

Pallet system X85

22 Pages

-

Conveyor system WL526X

16 Pages

-

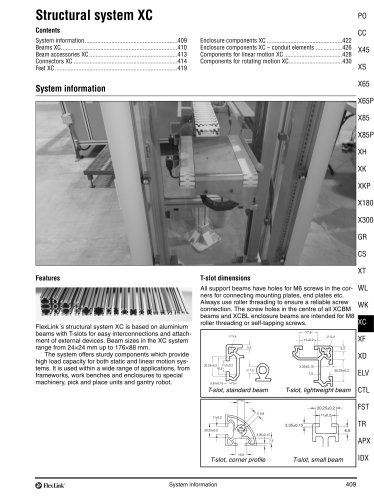

Structural system XC

22 Pages

-

Conveyor system XLX

8 Pages

-

Pallet system XT

50 Pages

-

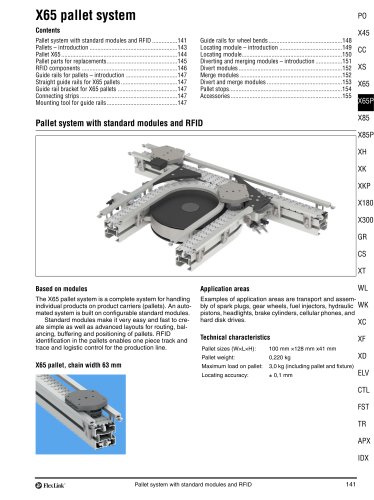

Pallet system X65

16 Pages

-

Conveyor system WL678X

16 Pages

-

Conveyor system X300X

14 Pages

-

Conveyor system X180X

14 Pages

-

Conveyor system X85X and X85Y

18 Pages

-

Profile system MS+

320 Pages

-

Product overview

24 Pages

-

Conveyor system WK

12 Pages

-

Conveyor system XW

20 Pages

-

Conveyor System WL

16 Pages

-

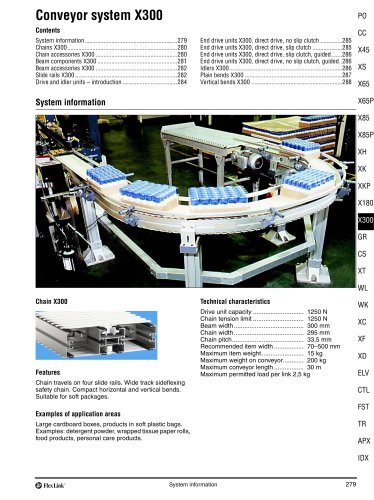

Conveyor System X300

10 Pages

-

Conveyor System X180

10 Pages

-

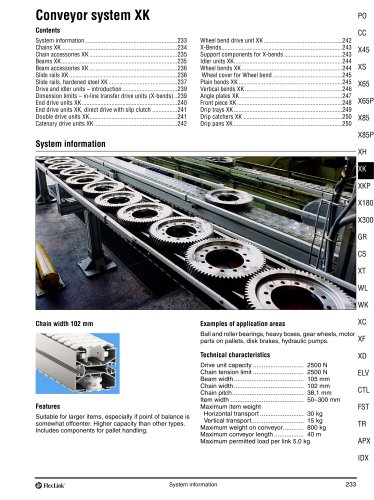

Conveyor System XK

20 Pages

-

Conveyor System XH

20 Pages

-

Conveyor System X85

34 Pages

-

Conveyor System X65

30 Pages

-

Conveyor System XS

12 Pages

-

Conveyor System X45

48 Pages

Archived catalogs

-

Conveyor System XL

28 Pages