Catalog excerpts

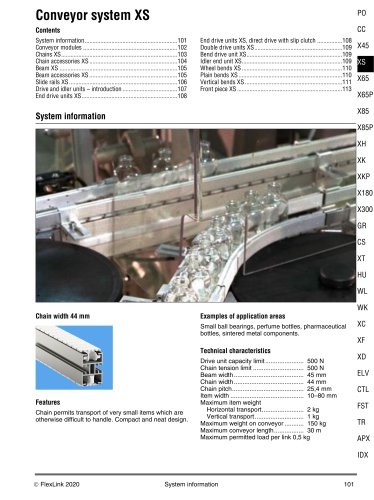

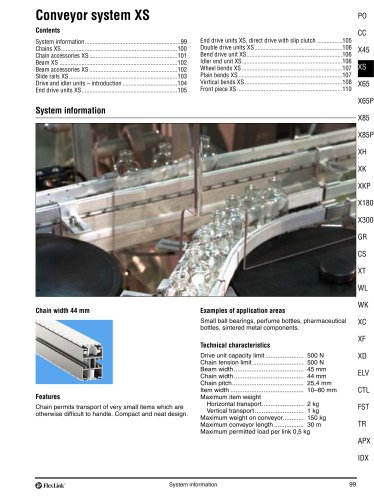

System information Examples of application areas Small ball bearings, perfume bottles, pharmaceutical bottles, sintered metal components. Technical characteristics Features Chain permits transport of very small items which are otherwise difficult to handle. Compact and neat design. System information

Open the catalog to page 1

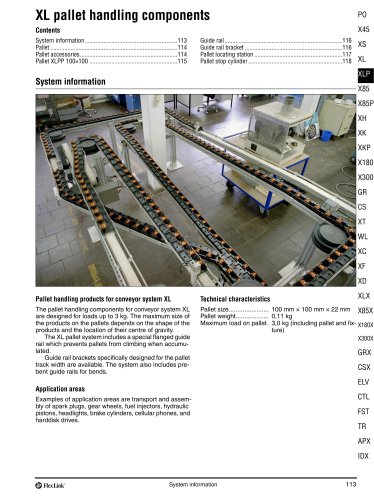

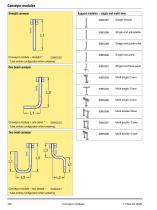

Conveyor modules Straight conveyor Support modules – single and multi-lane 5995387 Single two/three-point Multi single 2 lane Multi single 3 lane Multi single 4 lane Multi double 3 lane Single foot plate Conveyor module – straight * Single end guide roller Single diecast Multi double 4 lane *Use online configurator when ordering L1 Conveyor module – one bend * *Use online configurator when ordering L2 Conveyor module – two bends * *Use online configurator when ordering Conveyor modules

Open the catalog to page 2

Chains XS Other chains Plain chain See the Chain guide for selection of other chains. Chain installation See Appendix “D. Chain installation” on page 527, Cleated chain, Type G X65 Plain chain Length 5 m Plain chain (Ultra low wear) Length 5 m Plain link kit (Ultra low wear) Note. Link kit contains 10 links, 10 pivot, 10 steel pins. Cleated chain, Type D Cleated chain Type G Length 5 m h=3 h=5 h=9 XSTF 5×3 G XSTF 5×5 G XSTF 5×9 G Use the online configurator to specify and order. Cleated link kits h=3 h=5 h=9 Note. Link kit contains 10 links, 10 pivot, 10 steel pins. Cleated chain Type D,...

Open the catalog to page 3

Chain accessories XS Plastic pivot for chain XLTT 9×16 Pin insertion tool for chain XLMJ 4 Pin insertion tool XS-X65-XT XS-X65-XT, PRO version* XLMJ 4 XLMJ 4 P *This product is recommended for frequent users.

Open the catalog to page 4

X65P Beam Length 3000 +10/-0 mm Length to order (30- 3000 mm) Slide rail: see page 106 Beam accessories XS Connecting strip with set screws Beam spacer Connecting strip with set screws h=20, a=30, b=50, L=130 Cover strip for T-slot, PVC Beam spacer Aluminium, anodized Length 3 m Cover strip for T-slot, PVC Length 25 m For connection of two conveyor beams side to side. Use M8 screw and slot nut. Two holes must be drilled, one through the spacer (9 mm) and one through the beam, to allow insertion of the screw. The diameter of the second hole depends on the size of the screw head.

Open the catalog to page 5

Slide rails XS Plastic slide rails for XS beam XSCR 25 Rivet crimping clamp XSCR 25 U Slide rail Length 25 m HDPE (μ=0,1–0,25) (Black) PVDF (μ=0,15–0,35) (Natural white) UHMW-PE (μ=0,1–0,25) (White) PA-PE (μ=0,1–0,25) (Grey) XSCR 25 XSCR 25 P XSCR 25 U XSCR 25 H Rivet crimping clamp for XS For 3 mm rivets Cover strip Mounting tool for slide rail 4 3,4 1,6 Mounting tool for slide rail XS, X65 XLMR 140 Aluminium rivets Aluminium rivets 3 mm for XS conveyors Extra slide rail in plain bends must be anchored using plastic screws due to lack of space for the rivet crimping tool. Note. Contains...

Open the catalog to page 6

Drive and idler units – introduction CC Drive unit types The XS system includes several configurations, including direct driven units with suspended motor and transmission chain as well as drive units. Available motors include variable speed types (V) as well as fixed speed motors (F). Note that dimensions relating to drive unit motors depend on the motor specified during the configuration. End drive units Size Direct drive, slip clutch Suspended motor, transmission chain, slip clutch Wheel bend drive units Suspended motor, transmission chain, slip clutch Double drive units Size Suspended...

Open the catalog to page 7

End drive units XS End drive unit, suspended motor, slip clutch 80 End drive unit, suspended motor, slip clutch 80 End drive unit Fixed speed up to 60 m/min Transmission on left side Fixed speed Without motor (ISO) Without motor (ANSI) XSEB XSEB 0 HL XSEB 0 HLA Maximum traction force: 500 N. See page 22. Use online configurator when ordering. Effective track length: 0,80 m End drive unit Fixed speed up to 60 m/min Transmission on right side Fixed speed Without motor (ISO) Without motor (ANSI) XSEB XSEB 0 HR XSEB 0 HRA Maximum traction force: 500 N. See page 22. Use online configurator when...

Open the catalog to page 8

Double drive units XS Double drive unit, suspended Double drive unit, suspended A Double drive unit Fixed speed up to 60 m/min Transmission on left side A = 55 mm Fixed speed Without motor (ISO) Without motor (ANSI) A = 90–350 mm Without motor (ISO) Without motor (ANSI) XSEB DD XSEB 0 HLD55 XSEB 0 HLAD55 XSEB 0 HLD– XSEB 0 HLAD– Maximum traction force: 500 N. See page 22. Use online configurator when ordering. Effective track length: 0,80 m Double drive unit Fixed speed up to 60 m/min Transmission on right side A = 55 mm Fixed speed Without motor (ISO) Without motor (ANSI) A = 90–350 mm...

Open the catalog to page 9

Wheel bends XS Wheel bend, 30° Effective track length: 0,25 m 1-way (0,50 m 2-way) Effective track length: 0,40 m 1-way (0,80 m 2-way) Effective track length: 0,30 m 1-way (0,60 m 2-way) Effective track length: 0,65 m 1-way (1,30 m 2-way) Plain bends XS Plain bend, 30° XSBP 30R500 XSBP 30R700 XSBP 30R1000 XSBP 45R500 XSBP 45R700 XSBP 45R1000

Open the catalog to page 10

Plain bends XS (continued) Plain bend, 60° XSBP 60R500 XSBP 60R700 XSBP 60R1000 Effective track length: 0,20 m 1-way (0,40 m 2-way) Effective track length: 0,35 m 1-way (0,65 m 2-way) Effective track length: 0,22 m 1-way (0,44 m 2-way) Effective track length: 0,45 m 1-way (0,80 m 2-way)

Open the catalog to page 11

Vertical bends XS (continued) Vertical bend, 60° Effective track length: 0,50 m 1-way (0,95 m 2-way) Effective track length: 0,70 m 1-way (1,30 m 2-way) The bend is cut in the middle to the desired angle and assembled using connecting strips. The angle “E” must be specified when ordering.

Open the catalog to page 12

Front piece XS Front piece Bend support for front piece 30 Front piece Length 3 m Sliding strip for front piece Front piece lower bend Sliding strip for front piece Length 2 m The sliding strip must be anchored to the front piece. Rivets and tools for anchoring: see page 106. Front piece upper bend Includes connecting strip with screws Includes connecting strip with screws Linkage kit for front piece Kit includes two support pairs and one locking device.

Open the catalog to page 13All FlexLink catalogs and technical brochures

-

WLX222

16 Pages

-

Food and dairy

8 Pages

-

WLX

2 Pages

-

Enclosures and safety guards

158 Pages

-

PRODUCTION FLOW SOLUTIONS

8 Pages

-

Elevator

4 Pages

-

Modular plastic belt conveyor WK

14 Pages

-

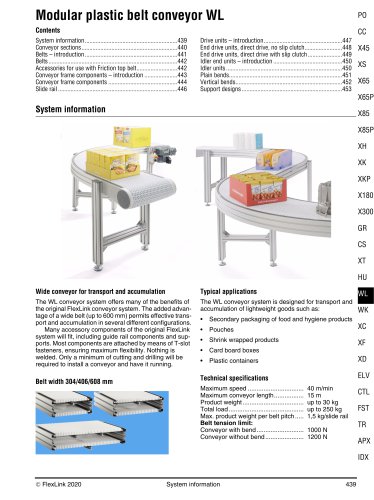

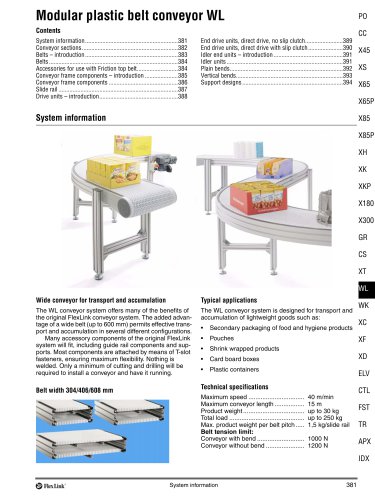

Modular plastic belt conveyor WL

16 Pages

-

Conveyor system X65

32 Pages

-

Product overview

498 Pages

-

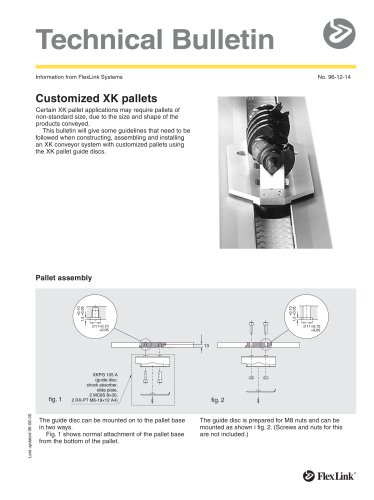

Customized XK pallets

2 Pages

-

GENIUS PCB HANDLING SYSTEM

66 Pages

-

Product Catalogue

160 Pages

-

Configurable Components

20 Pages

-

SMART PCB handling system

12 Pages

-

GENIUS line

8 Pages

-

SMART line

4 Pages

-

Pallet system XTH

4 Pages

-

Conveyor system WL374X

16 Pages

-

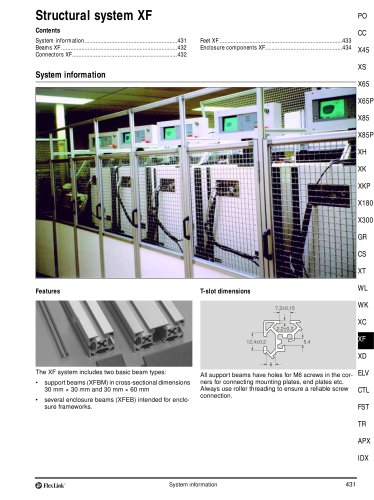

Structural system XF

8 Pages

-

Structural system XD

4 Pages

-

Spiral elevator

2 Pages

-

Pallet system XK

16 Pages

-

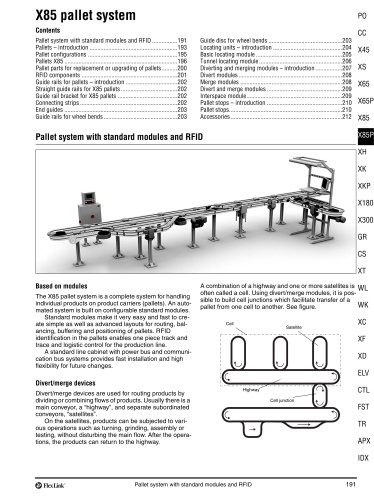

Pallet system X85

22 Pages

-

Conveyor system WL526X

16 Pages

-

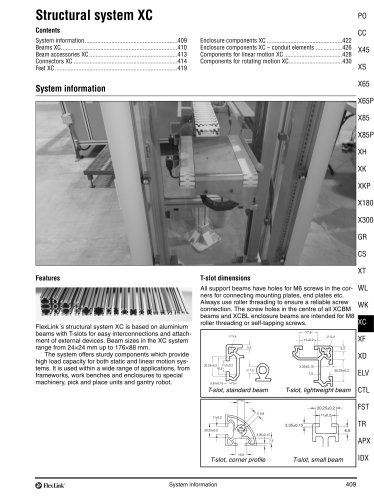

Structural system XC

22 Pages

-

Conveyor system XLX

8 Pages

-

Pallet system XT

50 Pages

-

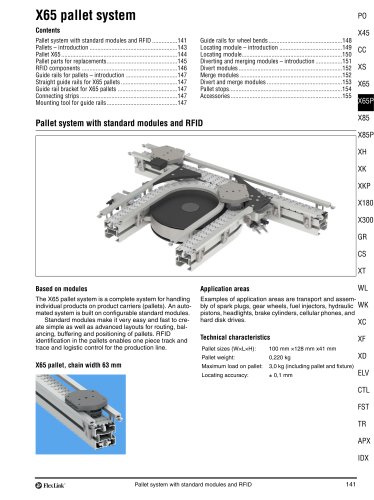

Pallet system X65

16 Pages

-

Conveyor system WL678X

16 Pages

-

Conveyor system X300X

14 Pages

-

Conveyor system X180X

14 Pages

-

Conveyor system X85X and X85Y

18 Pages

-

Profile system MS+

320 Pages

-

Product overview

24 Pages

-

Conveyor system WK

12 Pages

-

Conveyor system XW

20 Pages

-

Conveyor System WL

16 Pages

-

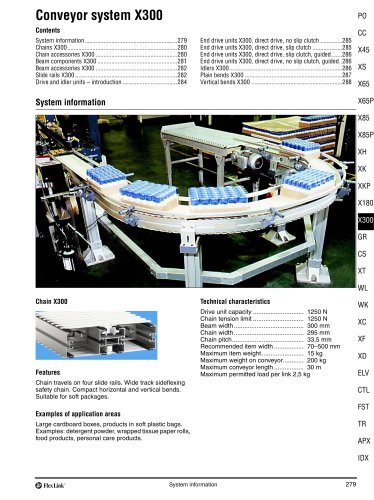

Conveyor System X300

10 Pages

-

Conveyor System X180

10 Pages

-

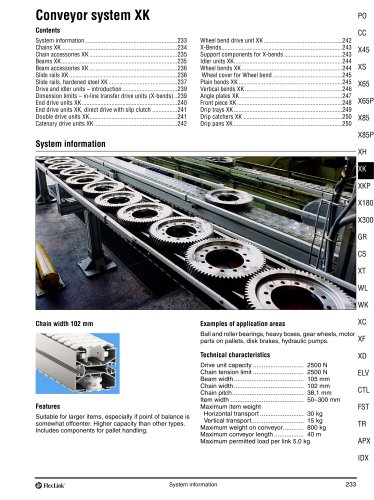

Conveyor System XK

20 Pages

-

Conveyor System XH

20 Pages

-

Conveyor System X85

34 Pages

-

Conveyor System X65

30 Pages

-

Conveyor System XS

12 Pages

-

Conveyor System X45

48 Pages

Archived catalogs

-

Conveyor System XL

28 Pages