Website:

FlexLink

Website:

FlexLink

Group: Coesia

Catalog excerpts

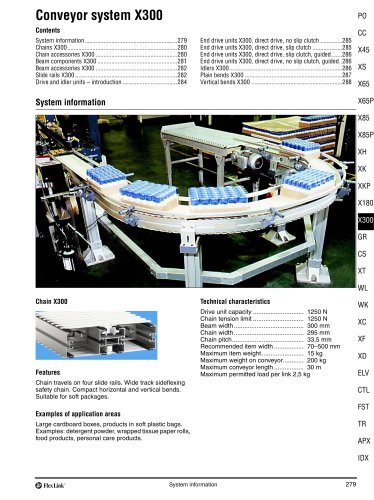

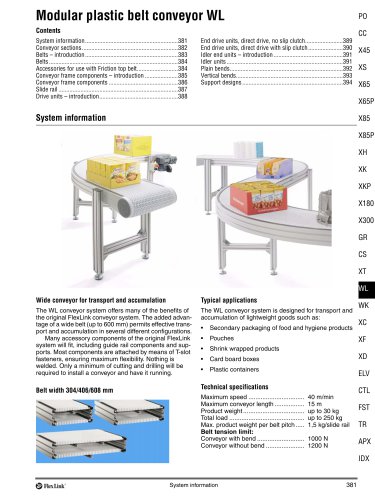

System information Technical characteristics Chain travels on four slide rails. Wide track sideflexing safety chain. Compact horizontal and vertical bends. Suitable for soft packages. Examples of application areas Large cardboard boxes, products in soft plastic bags. Examples: detergent powder, wrapped tissue paper rolls, food products, personal care products. System information

Open the catalog to page 1

Chain accessories X300 Plastic pivot Each kit contains 25 items. Plain chain Length 3 m * Link kit contains 10 links, 10 pivots, 10 steel pins Each kit contains 25 items. 3 7 Pin insertion tool for chain Friction top chain Length 3 m Friction top chain Length 3 m Pin insertion tool X85--X180-X300 XMMJ 6 X85-X180-X300-XH, PRO version* XBMJ 6 P *This tool is recommended for frequent users Use the online configurator to specify and order. Friction top link kit* Kit with 10 links *Note. Links are delivered as a kit containing 10 links and the necessary steel pins and plastic pivots. Other...

Open the catalog to page 2

Beam section kit (300 mm version) Spacer for outer beam sections Spacer, aluminium, one pair Beam section kit Length 3 m (3000 ±5 mm) XBCB 3A300 Length to order (500- 3000 mm) XBCB LA300 The beam section is delivered unassembled. Slide rail: see page 282 Including screws and nuts. For construction of 300 mm wide beam sections. Maximum distance between spacers is 0,5 m. Beam (mid-section) Beam (mid-section) Length 3 m (3030 ±5 mm) XBCB 3A85 Length to order (500- 3000 mm) XBCB LA85 Beam (outer section) WK XC Beam (outer section) Length 3 m (3030 ±5 mm) XBCB 3A H Length to order (500- 3000 mm)...

Open the catalog to page 3

Beam components X300 (continued) Beam clip assembly Beam section for chain installation Beam clip assembly Beam section for chain installation Including connecting strips and screws Including M8 screw and locking nut. Use minimum 5 clips per meter. Place clips 100 mm from each end. Note. Must be ordered in multiples of 10. Beam accessories X300 Connecting strip with set screws Cover strip for T-slot, aluminium Connecting strip with set screws h=20, a=44, b=44, L=160 Note. Must be ordered in multiples of 10 Cover strip for T-slot Aluminium, anodized Length 2 m Cover strip for T-slot, PVC...

Open the catalog to page 4

Slide rails X300 (continued) Mounting tool for slide rail, X300 Drill fixture for slide rail Drill fixture for X65-X85-XH-XKMounting tool for slide rail Aluminium rivets Rivet crimping pliers Aluminium rivets 4 mm for XKX180-X300 conveyors, brown Rivet crimping pliers for X65-X85-XHXK-X180-X300 For 4 mm rivets Extra slide rail in plain bends must be anchored using plastic screws due to lack of space for the rivet crimping tool. Note. Must be ordered in multiples of 250. Rivet crimping clamp Plastic screws for slide rail Plastic screws 5 mm for XS-X65-X85XH-X180-X300 beams XLAG 5 See...

Open the catalog to page 5

Drive and idler units – introduction Drive unit types The X300 system includes direct driven units with or without slip clutch. Available motors include variable speed types (V) as well as fixed speed motors (F). End drive units Size Direct drive, no slip clutch Direct drive, slip clutch Heavy, guided Motor specifications Motors are available for 230/400 V, 50 Hz and 230/460 V or 330/575 V, 60 Hz. All motors can be connected for delta or star configuration by means of jumpers. Variable speed motors are SEW Movimot, 380–500 V. Note that variable speed motors include a control box that adds...

Open the catalog to page 6

End drive units X300, direct drive, no slip clutch End drive units X300, direct drive, slip clutch End drive unit, direct drive, no slip clutch 80 End drive unit, direct drive, slip clutch 80 XKP X180 End drive unit, direct drive Fixed speed up to 60 m/min Variable speed up to 80 m/min Motor on left side Fixed/variable speed * Without motor Motor on right side Fixed/variable speed * Without motor XBEB A300 XBEB 0A300HNLP XBEB A300 XBEB 0A300HNRP Maximum traction force: 1250 N. See page 23. *Use online configurator when ordering. Effective track length: 0,80 m End drive unit, direct drive...

Open the catalog to page 7

End drive units X300, direct drive, slip clutch, guided End drive unit H, guided chain, slip clutch 80 End drive units X300, direct drive, no slip clutch, guided End drive unit H, guided chain, no slip clutch End drive unit Direct drive with guided chain. Adjustable slip clutch. Maximum traction force: up to 1250 N. Fixed speeds up to 60 m/min. Variable speed up to 80 m/min. Motor on left side: Fixed/variable speed * Without motor Motor on left side: Motor on right side: Fixed/variable speed * Without motor End drive unit Direct drive with guided chain. No slip clutch. Maximum traction...

Open the catalog to page 8

Effective track lengths: R700: 1,55 m (top+bottom) R1000: 1,85 m (top+bottom) Effective track lengths: R700: 2,30 m (top+bottom) R1000: 2,90 m (top+bottom) Plain bend, 45°±1° R=700±10 mm R=1000±10 mm Effective track lengths: R700: 1,90 m (top+bottom) R1000: 2,40 m (top+bottom) Effective track lengths: R700: 3,00 m (top+bottom) R1000: 3,95 m (top+bottom)

Open the catalog to page 9

Vertical bend, 5° XBBV 5A300R750 Four outer section beam pieces, unassembled. Effective track length: 0,50 m (top+bottom) Vertical bend, 15° XBBV 15A300R750 Four outer section beam pieces, unassembled. Effective track length: 0,75 m (top+bottom) Vertical bend, 45° XBBV 45A300R750 Four outer section beam pieces, unassembled. Effective track length: 1,5 m (top+bottom) 288 Vertical bends X300 ©Fkxlink'

Open the catalog to page 10All FlexLink catalogs and technical brochures

-

Conveyor system XW

20 Pages

-

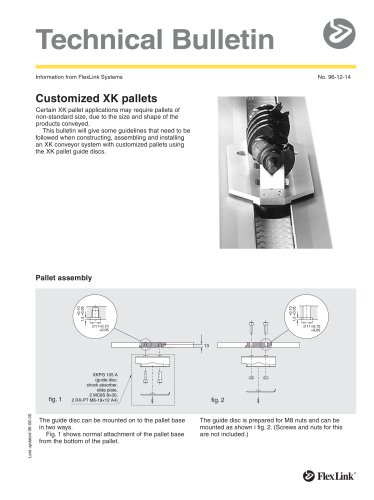

Customized XK pallets

2 Pages

-

WLX222

16 Pages

-

Food and dairy

8 Pages

-

WLX

2 Pages

-

Enclosures and safety guards

158 Pages

-

PRODUCTION FLOW SOLUTIONS

8 Pages

-

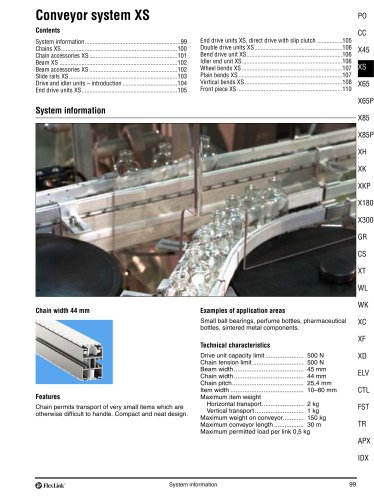

Conveyor system XS

14 Pages

-

Elevator

4 Pages

-

Modular plastic belt conveyor WK

14 Pages

-

Modular plastic belt conveyor WL

16 Pages

-

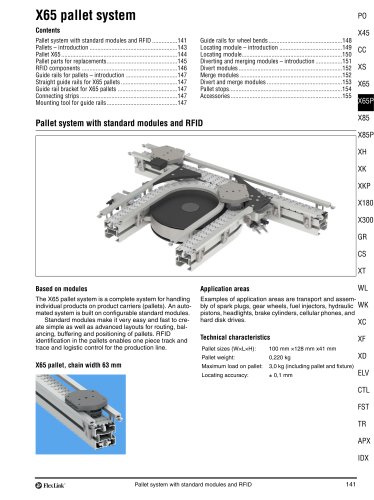

Conveyor system X65

32 Pages

-

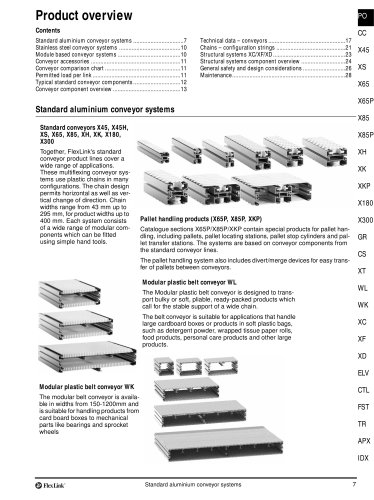

Product overview

498 Pages

-

Customized XK pallets

2 Pages

-

GENIUS PCB HANDLING SYSTEM

66 Pages

-

Product Catalogue

160 Pages

-

Configurable Components

20 Pages

-

SMART PCB handling system

12 Pages

-

GENIUS line

8 Pages

-

SMART line

4 Pages

-

Pallet system XTH

4 Pages

-

Conveyor system WL374X

16 Pages

-

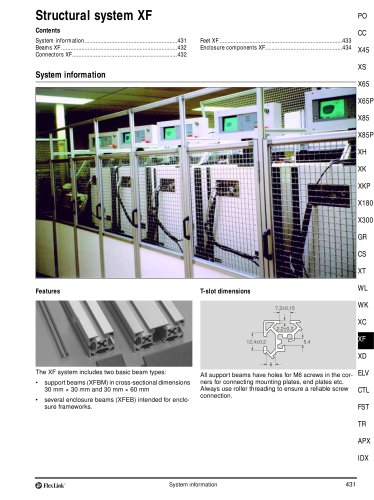

Structural system XF

8 Pages

-

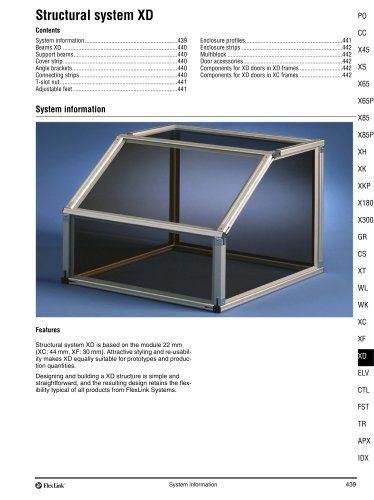

Structural system XD

4 Pages

-

Spiral elevator

2 Pages

-

Pallet system XK

16 Pages

-

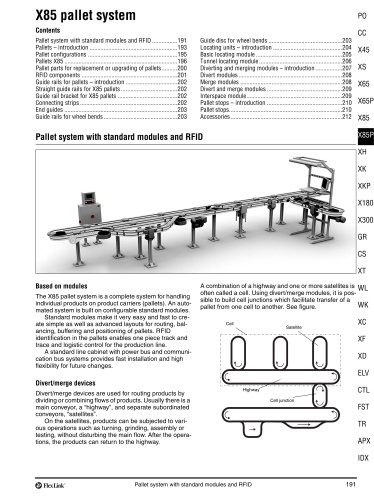

Pallet system X85

22 Pages

-

Conveyor system WL526X

16 Pages

-

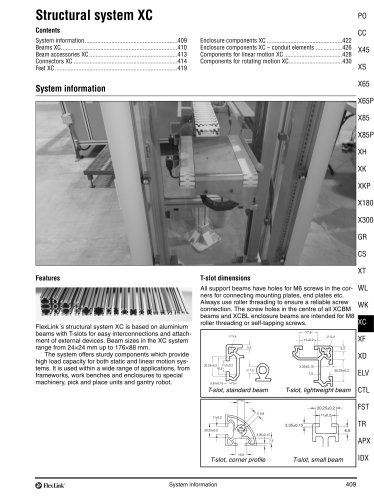

Structural system XC

22 Pages

-

Conveyor system XLX

8 Pages

-

Pallet system XT

50 Pages

-

Pallet system X65

16 Pages

-

Conveyor system WL678X

16 Pages

-

Conveyor system X300X

14 Pages

-

Conveyor system X180X

14 Pages

-

Conveyor system X85X and X85Y

18 Pages

-

Profile system MS+

320 Pages

-

Product overview

24 Pages

-

Conveyor system WK

12 Pages

-

Conveyor system XW

20 Pages

-

Conveyor System WL

16 Pages

-

Conveyor System X180

10 Pages

-

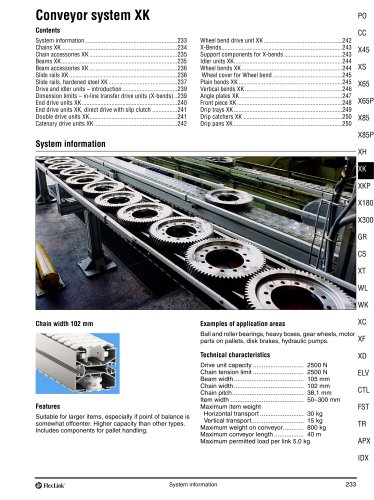

Conveyor System XK

20 Pages

-

Conveyor System XH

20 Pages

-

Conveyor System X85

34 Pages

-

Conveyor System X65

30 Pages

-

Conveyor System XS

12 Pages

-

Conveyor System X45

48 Pages

Archived catalogs

-

Conveyor System XL

28 Pages