Catalog excerpts

PRODUCT CATALOGUE ALUMINUM CONVEYOR AND PALLET HANDLING SYSTEMS

Open the catalog to page 1

Elevating © Copyright FlexLink 2023 The contents of this publication are the copyright of the publishers and may not be reproduced (even extracts) unless permission is granted. Every care has been taken to ensure the accuracy of the information but no liability can be accepted for any errors or omissions. The right is reserved to make design modifications. Patents Essential parts of the FlexLink product range are protected by patents and design regulations. Drawings are made to European standards.

Open the catalog to page 2

About the catalogue The catalogue contains conveyor components, conveyor modules, spiral conveyors and structural system components. The catalogue structure follows the product lines in order to simplify search for the right products. The technical information is intended for the main target group: experienced users. Basic engineering information is available in other documents and on www.flexlink.com. Highlights New height and chain types for compact spiral elevator Enhanced transferring with S-bends The compact spiral allows manufacturers to increase available production floor space...

Open the catalog to page 3

Pallet handling components XT

Open the catalog to page 7

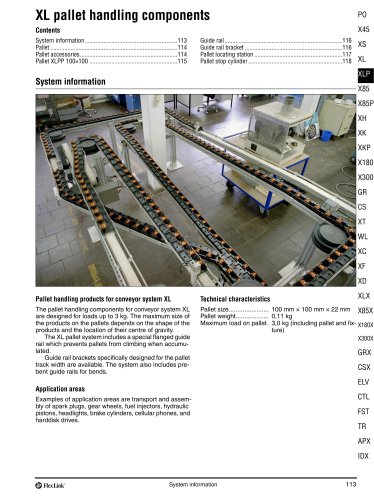

The product range FlexLink´s products in this catalogue Conveyor systems Pallet systems FlexLink´s conveyors based on aluminium with low friction slide rails guiding a plastic multi-flexing chain. Products to be conveyed travel directly on the conveyor, or on puck/pallets/carriers. Weights range from a few grams up to 30 kg in many shapes. The pallet systems are based on FlexLink´s conveyors with product carrier sizes from 100×128 mm up to 1040x1040 mm. Standard solutions like locating stations, diverters and elevators together with our range of linear units, frameworks and enclosures,...

Open the catalog to page 10

An automated product flow The automation of your production flow means that you can leverage on the investment in product development, buildings, machinery and operators' competence. Today's manufacturing environment has to cope with instantly changing market demand, frequent product changes, tight cost frames, global competition and minimization of risk. Assembly and test The first floor includes automated and manual stations for kitting, assembly, and test. An automated product flow

Open the catalog to page 11

Software and training The entire plant is supervised by an overall on-line control system which takes care of order handling and production control. The training of operators is facilitated by customized training programs. Component manufacturing The ground floor includes two sequential lines for component manufacturing, finished product packaging and a final palletizer. FlexLink´s conveyors serve the machines and include transfer lines, buffers, elevators, lowerators, diverters, and merge stations. An automated product flow

Open the catalog to page 12

Chute for quick and efficient lowering Automatic machinery for gear wheels Inhalator packaging and filling line Multi-functional wedge conveyor for cosmetic bottles Tray packaging Highway and satellite concept

Open the catalog to page 13

Applications (continued) Hygienic filling line Repair line Printed circuit board assembly line Production software Assembly system In-line case elevation

Open the catalog to page 14

Portal for simplified engineering and business Configure modules Increase your efficiency when planning, purchasing, building, installing, running and servicing automation solutions based on FlexLink´s products. FlexLink’s homepage, www.flexlink.com, offers in-depth technical information and My FlexLink, the portal for online ordering and engineering tool updates. Order archive Please navigate through the different sections of the site and find out how it can simplify your next automation installation. FlexCAD, Add-on to AutoCAD Calculation Tool Online CAD Library to download CAD block in...

Open the catalog to page 15

Product overview Standard aluminium conveyor systems Together, FlexLink's standard conveyor product lines cover a wide range of applications. These multiflexing conveyor systems use plastic chains in many configurations. The chain design permits horizontal as well as vertical change of direction. Chain widths range from 43 mm up to 295 mm, for product widths up to 400 mm. Each system consists of a wide range of modular components which can be fitted using simple hand tools. Pallet handling products (XT, HU, X65P, X85P, XKP) Catalogue sections X65P/X85P/XKP contain special products for...

Open the catalog to page 16

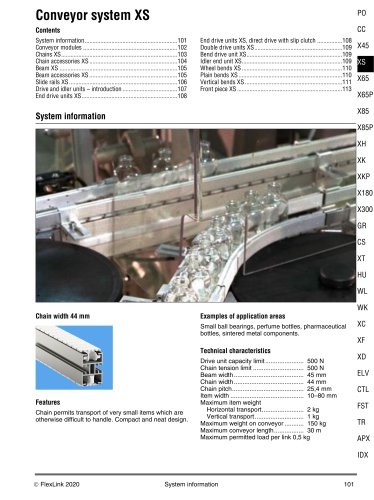

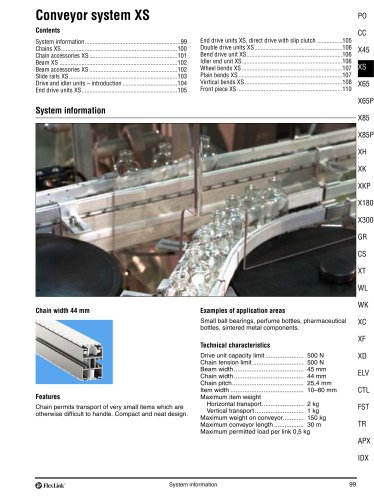

Conveyor system X45 (43 mm chain) Conveyor system XS (44 mm chain) Conveyor system X65/X65P (63 mm chain) Conveyor system X85/X85P (83 mm chain) Very compact conveyor system for small and light items. Modular design concept for simplified engineering, fast configuration and ordering. Chain permits transport of very small items which are otherwise difficult to handle. Compact and neat design. Suitable for a wide range of applications. Preferable in high speed applications. Includes components for pallet handling (X65P) and vertical wedge conveyors. Suitable for a wide range of applications....

Open the catalog to page 17

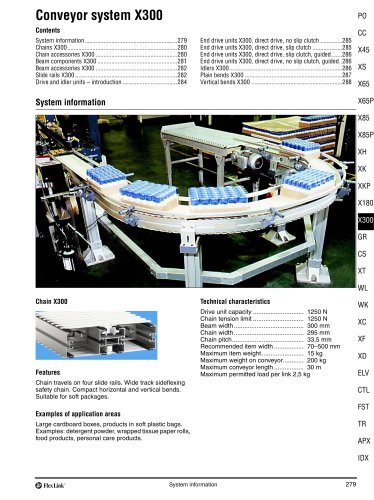

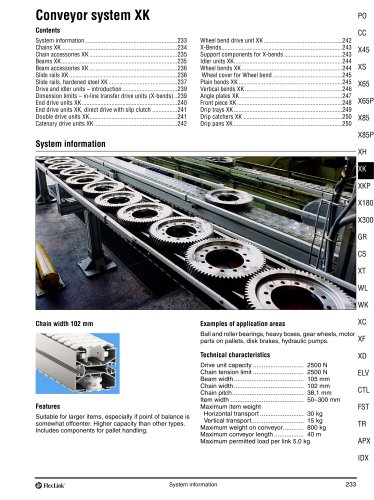

Conveyor system XH (103 mm chain) Conveyor system XK/XKP (102 mm chain) Conveyor system X180/X300 (175 mm/295 mm chain) Suitable for larger items, Suitable for larger items, especially if point of balance especially if point of balance is somewhat offcenter. is somewhat offcenter. Higher capacity than other types. Includes components Examples of application for pallet handling (XKP). areas Large ball bearings, turbo rotors, safety belt brackets, electric motors, shock absorbers, steering arm components, boxes. Examples of application areas Chain travels on four slide rails. Wide track...

Open the catalog to page 18

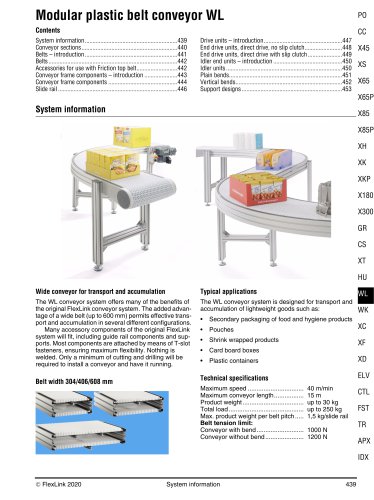

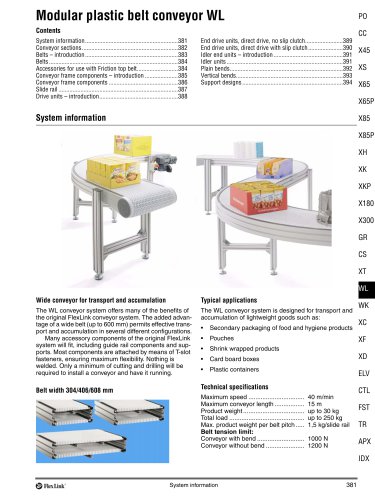

Modular plastic belt conveyor WK (150/225/300/600/900/1200 mm belt) Features The added advantage of a wide belt (up to 1200 mm) permits effective transport and accumulation in several different configurations. Examples of application areas The WK conveyor system is designed for transport and accumulation of lightweight goods such as: Secondary packaging of food and hygiene products, Pouches, Shrink wrapped products, Cardboard boxes, Plastic containers Standard aluminium conveyor systems

Open the catalog to page 19All FlexLink catalogs and technical brochures

-

WLX222

16 Pages

-

Food and dairy

8 Pages

-

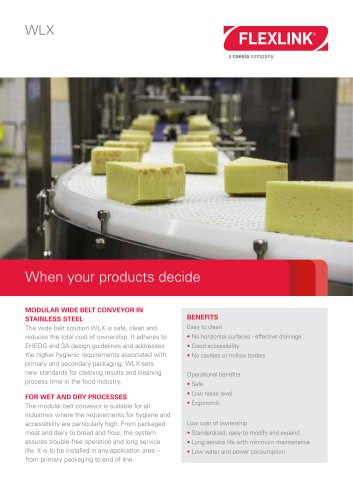

WLX

2 Pages

-

Enclosures and safety guards

158 Pages

-

PRODUCTION FLOW SOLUTIONS

8 Pages

-

Conveyor system XS

14 Pages

-

Elevator

4 Pages

-

Modular plastic belt conveyor WK

14 Pages

-

Modular plastic belt conveyor WL

16 Pages

-

Conveyor system X65

32 Pages

-

Product overview

498 Pages

-

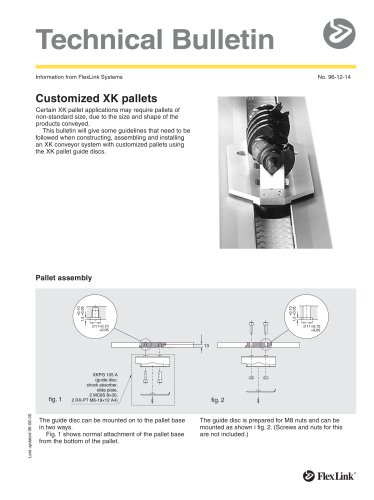

Customized XK pallets

2 Pages

-

GENIUS PCB HANDLING SYSTEM

66 Pages

-

Product Catalogue

160 Pages

-

Configurable Components

20 Pages

-

SMART PCB handling system

12 Pages

-

GENIUS line

8 Pages

-

SMART line

4 Pages

-

Pallet system XTH

4 Pages

-

Conveyor system WL374X

16 Pages

-

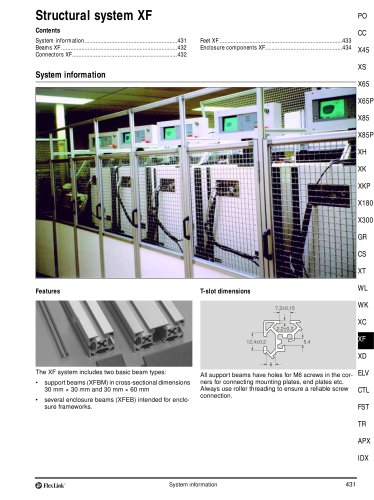

Structural system XF

8 Pages

-

Structural system XD

4 Pages

-

Spiral elevator

2 Pages

-

Pallet system XK

16 Pages

-

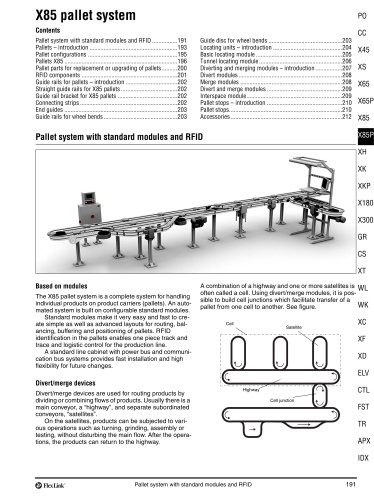

Pallet system X85

22 Pages

-

Conveyor system WL526X

16 Pages

-

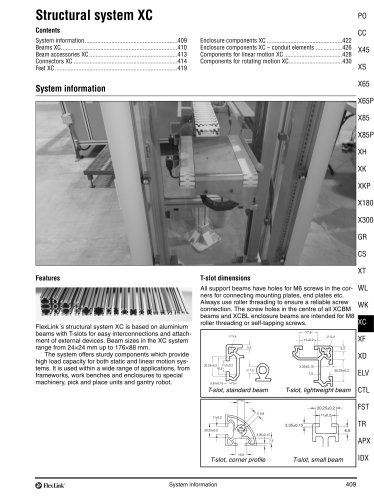

Structural system XC

22 Pages

-

Conveyor system XLX

8 Pages

-

Pallet system XT

50 Pages

-

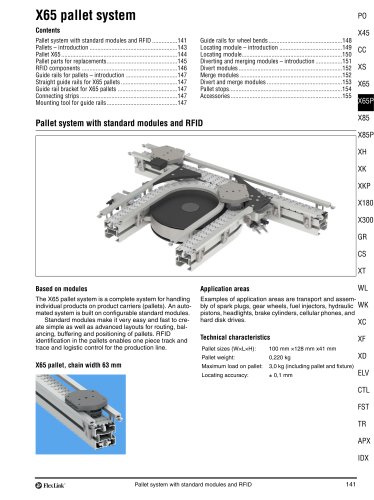

Pallet system X65

16 Pages

-

Conveyor system WL678X

16 Pages

-

Conveyor system X300X

14 Pages

-

Conveyor system X180X

14 Pages

-

Conveyor system X85X and X85Y

18 Pages

-

Profile system MS+

320 Pages

-

Product overview

24 Pages

-

Conveyor system WK

12 Pages

-

Conveyor system XW

20 Pages

-

Conveyor System WL

16 Pages

-

Conveyor System X300

10 Pages

-

Conveyor System X180

10 Pages

-

Conveyor System XK

20 Pages

-

Conveyor System XH

20 Pages

-

Conveyor System X85

34 Pages

-

Conveyor System X65

30 Pages

-

Conveyor System XS

12 Pages

-

Conveyor System X45

48 Pages

Archived catalogs

-

Conveyor System XL

28 Pages