Catalog excerpts

Technical specification FLUXUS® G70x Gas ultrasonic flowmeter for permanent installation Transmitter for permanent outdoor wall or pipe mounting Features • Precise bi-directional and highly dynamic flow measurement with the non-invasive clamp-on technology • High precision at fast and slow flow rates, high temperature and zero point stability • Automatic loading of calibration data and transducer detection for a fast and easy set-up (less than 5 min), providing precise and long-term stable results • User-friendly design • Transducers available for a wide range of inner pipe diameters and fluid temperatures • ATEX, IECEx, FM Class I Div. 2 approved transducers for hazardous areas available • Measurement is unaffected by gas density, viscosity, composition, dust, humidity, temperature or pressure Applications Designed for industrial use in harsh environments, in gas processing and natural gas extraction, chemical industry and in the petroleum industry. Practical applications: • Measurement on natural gas pipelines and in natural gas storage installations • Measurement of synthesized gas and injection gas • Measurement for the gas supply industry Measurement with transducers mounted with Variofix C

Open the catalog to page 1

Technical specification

Open the catalog to page 2

Technical specification Function Measurement principle In order to measure the flow of a fluid in a pipe, ultrasonic signals are used, employing the transit time difference principle. Ultrasonic signals are emitted by a transducer installed on the pipe and received by a second transducer. These signals are emitted alternately in the flow direction and against it. As the fluid in which the signals propagate is flowing, the transit time of the ultrasonic signals in the flow direction is shorter than against the flow direction. The transit time difference, ∆t, is measured and allows the...

Open the catalog to page 3

Technical specification Number of sound paths The number of sound paths is the number of transits of the ultrasonic signal through the fluid in the pipe. Depending on the number of sound paths, the following methods of installation exist: • reflection arrangement The number of sound paths is even. Both of the transducers are mounted on the same side of the pipe. Correct positioning of the transducers is easier. • diagonal arrangement The number of sound paths is odd. Both of the transducers are mounted on opposite sides of the pipe. In the case of a high signal attenuation by the fluid,...

Open the catalog to page 4

Technical specification Typical measurement setup RS485 (optional) power supply RS232 damping mat transmitter e.g. external pressure sensor temperature probe Example of a reflection arrangement with connection of the inputs to an external process pressure and process temperature measurement for standard volumetric flow rate calculation Standard volumetric flow rate The standard volumetric flow rate can be selected as physical quantity to be measured. It will be calculated internally by: · · V N = V . p/pN . TN/T . 1/K where · VN · V pN p TN T K standard volumetric flow rate operating...

Open the catalog to page 5

FLUXUS® G70x Technical specification

Open the catalog to page 6

Technical specification FLUXUS® G70x 1 G70***-A2: connection of the interface RS232 outside of explosive atmosphere (housing cover open)

Open the catalog to page 7

FLUXUS® G70x Technical specification

Open the catalog to page 8

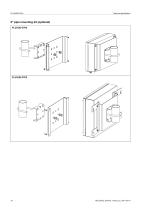

Technical specification fixing holes for wall mounting thread: 6x M20 x 1.5 cable gland: max. 6x M20 cable gland: max. 6x M20 with flat gasket and counter nut

Open the catalog to page 9

Technical specification 2" pipe mounting kit (optional) FLUXUS G704

Open the catalog to page 10

Technical specification FLUXUS® G70x power supply terminal strip KL3 binary inputs2 terminal strip KL4 terminal P1+...P2+, P1-...P2-2 The number, type and terminal assignment of the outputs and inputs will be customized.

Open the catalog to page 11

Technical specification Transducers Transducer selection Step 1a Select a Lamb wave transducer: transducer order code GLF 35 pipe wall thickness [mm] Step 1b If the pipe wall thickness is not in the range of the Lamb wave transducers, select a shear wave transducer: transducer order code 11 35 pipe wall thickness [mm] Step 2 Inner pipe diameter d dependent on the flow velocity v of the fluid in the pipe The transducers are selected from the characteristics (see next page). Lamb wave transducers are selected from the left column, shear wave transducers from the right column. Lamb wave...

Open the catalog to page 12

Technical specification inner pipe diameter and max. flow velocity for a typical application with natural gas, nitrogen, oxygen in reflection arrangement with 2 sound paths (Lamb wave transducers)/1 sound path (shear wave transducers)

Open the catalog to page 13

FLUXUS® G70x Technical specification inner pipe diameter and max. flow velocity for a typical application with natural gas, nitrogen, oxygen in reflection arrangement with 2 sound paths (Lamb wave transducers)/1 sound path (shear wave transducers) Step 3 min. fluid pressure Example step Step 4 for the characters 4...11 of the transducer order code (ambient temperature, explosion protection, connection system, extension cable) see page 15 Step 5 for the technical data of the selected transducer see page 16 et seqq.

Open the catalog to page 14

Technical specification FLUXUS® G70x Transducer order code 1,2 3 4 5, 6 7, 8 9...11 12, 13 no. of character

Open the catalog to page 15

FLUXUS® G70x Technical specification 1 depending on application, typical absolute value for natural gas, nitrogen, compressed air 2 shear wave transducer: typical values for natural gas, nitrogen, oxygen, pipe diameters for other fluids on request inner pipe diameter max. recommended/max. extended: in reflection arrangement and for a flow velocity of 15 m/s TSFLUXUS_G70xV2-1-1EN_Leu, 2017-03-10

Open the catalog to page 16

Technical specification FLUXUS® G70x 1 depending on application, typical absolute value for natural gas, nitrogen, compressed air 2 shear wave transducer: typical values for natural gas, nitrogen, oxygen, pipe diameters for other fluids on request inner pipe diameter max. recommended/max. extended: in reflection arrangement and for a flow velocity of 15 m/s

Open the catalog to page 17All FLEXIM Flexible Industriemesstechnik GmbH catalogs and technical brochures

-

PIOX ID

4 Pages

-

Busil

4 Pages

-

FLEXIM

2 Pages

-

Energy Efficiency

6 Pages

-

FLUXUS Cryo

2 Pages

-

Chemical Industry Solutions

8 Pages

-

FLUXUS CA

4 Pages

-

FLUXUS F401

2 Pages

-

Product Catalogue

24 Pages

-

FLUXUS SIL

4 Pages

-

FLUXUS XLF

2 Pages

-

Upstream Solutions

8 Pages

-

FLUXUS G601

29 Pages

-

FLUXUS G80x

33 Pages

-

Ultrasonic Flowmeters for Gases

12 Pages

-

Process Refactometer PIOX R

8 Pages

-

Portable ultrasonic flowmeter

12 Pages