Website:

FLEXCO

Website:

FLEXCO

Catalog excerpts

Keeping your belt HEAVY-DUTY MECHANICAL BELT FASTENING SYSTEMS A comprehensive line of mechanical belt fastening systems and belt conveyor maintenance tools that increase uptime and output.

Open the catalog to page 1

Around the world, the most respected name in belt conveyor solutions is Flexco. The reason is simple. Flexco belt splicing products have earned the reputation for unsurpassed quality and performance in the most demanding material handling applications on earth. Our fasteners set the industry's highest standards for design, ease of use, and reliability. The knowledgeable advice and proven solutions we provide our customers help keep conveyor efficiency high and conveyor operation costs low. OVER 100 YEARS OF SUCCESS HAS BEEN BUILT BY FOCUSING ON OUR We have learned to understand our...

Open the catalog to page 2

WHY CHOOSE FLEXCO? SAFETY. At Flexco, the safety of our workers and our customers is our top priority. • Many of our products have built-in safety features to help prevent on-the-job injuries. SERVICE. We believe that our commitment to the customer really sets us apart from our competition. When our customers call, we answer, dropping everything to help them solve their problems so they can keep their belt conveyor lines running. We have a global network of distributors, service providers, field technicians, and sales engineers who understand our products inside and out-all with a...

Open the catalog to page 3

THE MECHANICAL FASTENER ADVANTAGE No matter what you’re moving, minimizing downtime and maximizing output are always top priorities—and they can be significantly affected by the way you splice your belts. Most belt conveyor operations rely on one or both common methods of splicing: • Mechanical Belt Fastening - The process of joining belt ends by metal hinges or plates • Vulcanization - The process of joining belt ends through heat or chemicals Mechanical Belt Fasteners Combine Strength and Durability with Affordability and Easy Installation Unique Advantages of Mechanical Fasteners....

Open the catalog to page 4

Vulcanization—whether hot or cold—is a time-consuming process that requires special skills, expensive equipment, extreme accuracy in the cutting and stripping of belt ends, and a thorough knowledge of solvents, bonding materials, and compatible cover and fill materials. Every splicing method has its limitations, so it's essential to get the facts before you decide how to splice. VULCANIZATION - SOME COMMON MISCONCEPTIONS All Belts Can Be Vulcanized. • Old and/or worn fabric belts are not well-suited to vulcanizing because the layers are weaker and will become brittle when heat is applied. •...

Open the catalog to page 5

UNDERSTANDING MECHANICAL FASTENERS HOW DO MECHANICAL FASTENERS WORK? The way belts are manufactured has evolved over the years—and so have mechanical belt fasteners. Because belting today tends to be thinner and made of synthetic materials, Flexco has designed fasteners with lower profiles that grip almost any belt carcass. Our fasteners achieve their holding power through a combination of compression and penetration. They feature plates that apply firm, even pressure to top covers. Some systems, like our rivet-style fasteners, are able to penetrate the belt without damaging carcass fibers....

Open the catalog to page 6

HINGED PLATE OR SOLID PLATE FASTENERS? Hinged Plate • • • • • Easy joint separation: Hinged fasteners can be separated in order to remove, extend, or clean belts, simply by removing the hinge pin. Hinged fasteners can be spliced in the shop. This means only the hinge pin has to be inserted on-site. If belts of slightly different thicknesses must be joined, this can be accomplished using hinged fasteners. Used with smaller pulley diameters. Not recommended for highly abrasive applications or with belts conveying fine materials. Ideal for larger pulley diameters requiring higher tension belt...

Open the catalog to page 7

FLEXCO® MECHANICAL FASTENING SYSTEMS SYSTEM SELECTION GUIDE Flexco® BR™ Rivet Solid Plate Market Applications Flexco® SR™ Rivet Hinged Heavy-duty conveyor and Underground mining, elevator belts commonly construction equipment with used for handling sand, smaller pulleys, asphalt gravel, crushed stone, grain, coal, cement and salt Flexco® Bolt Solid Plate Higher-tension main haulage belts used in coal, hard-rock mining, foundries, grain elevators, aggregate plants, and steel mills Flexco® Bolt Hinged Construction and road Tough mining environments equipment, coal, salt, requiring a...

Open the catalog to page 8

FASTENER METALS AND AVAILABILITY To maximize fastener service life, fastener material must be matched to the application. Flexco manufactures fasteners from a broad range of materials. Our selection makes it easy to specify a fastener that will deliver maximum performance in a variety of conditions—from wet and abrasive applications to highly corrosive environments. Steel: Standard fastener metal that is not recommended for environments where corrosion can occur from acids and chemicals. Galvanized Steel: For basic applications, galvanized steel is recommended. It is magnetic, offers good...

Open the catalog to page 9

FLEXCO® RIVET SOLID PLATE FASTENING SYSTEM The Flexco® BR™ Rivet Solid Plate Fastening System is recommended for high-tension applications, and has a staggered, multiple-point attachment for a long-lasting hold. Ideal for use with straight-warped belts because rivets separate the fibers instead of displacing the carcass. • Low-profile, Scalloped Edge® design is conveyor component compatible • Wide, heavy-gauge plates promote long wear life, with a sift-free splice • Rivet-attached for maximum resistance to pull-out • Compatible with troughed belts • Available in Steel, Stainless, MegAlloy®,...

Open the catalog to page 10

INSTALLATION TOOLS Flexco Rivet Plate Fasteners are installed with a portable installation tool and a hammer or power tool. Hammer Installation Options Fastener Size Installation Tool Aluminum MBRT6 Applicator Tool MBRTA Applicator Tool Tool base, multiple guide blocks, two multiple drive rods, one bridge removal tool, one nut driver, two hammers, lubricant, and tool box Aluminum MBRT10 Applicator Tool Tool base, two multiple guide blocks, one multiple drive rod, one bridge removal tool, one hammer, and lubricant Tool base, two multiple guide blocks, one multiple drive rod, one bridge...

Open the catalog to page 11All FLEXCO catalogs and technical brochures

-

DRX™ Dynamic Bed Series

2 Pages

-

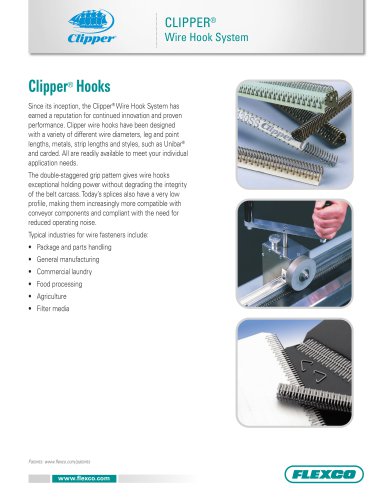

CLIPPER® Wire Hook System

12 Pages

-

CLIPPER® Production Lacers

2 Pages

-

CFC Secondary Cleaner

2 Pages

-

BELT-DRIVEN BRUSH CLEANER

2 Pages

-

CLIPPER®

2 Pages

-

NOVITOOL®

2 Pages

-

SUPER-SCREW®

8 Pages

-

PT Smart™

2 Pages

-

TUG™ HD® Belt Clamps

2 Pages

-

Bolt Hinged Fastener System

4 Pages

-

MOTORIZED BRUSH CLEANER

2 Pages

-

Flexco SR Rivet Hinged

4 Pages

-

HV2 Precleaner with V-Tips

2 Pages

-

FGP Food Grade Precleaner

2 Pages

-

EZIB Flexco Impact Beds

2 Pages

-

electric belt cutter

2 Pages

-

DRX? 3000 Dynamic Beds

2 Pages

-

Clipper® Production Lacers

2 Pages

-

clipper® G Series Lacing

2 Pages

-

Chevron Belt Cleaner

2 Pages

-

Belt Conveyor Products Guide

24 Pages

-

BCP Overview

28 Pages

-

Belt Positioner Literature

2 Pages

-

MMP

2 Pages

-

H - Types

2 Pages

-

EZP-LS

2 Pages

-

Belt cleats

2 Pages

-

FSK Belt Skiver

2 Pages

-

SmartClamp? Belt Clamps

2 Pages

-

Far-Pul® HD® Belt Clamps

2 Pages

-

PT Smart? Tracking Insights

2 Pages

-

EZP1 Precleaner

2 Pages

-

Flexco Light Duty Products

8 Pages

-

CFMTS

9 Pages

Archived catalogs

-

2022 BELT CONVEYOR PRODUCTS

32 Pages

-

2015 BELT CONVEYOR PRODUCTS

17 Pages

-

X1642

4 Pages

-

X2088

2 Pages

-

X1893

2 Pages

-

X1207

2 Pages

-

Flexco Product Handbook

100 Pages

-

Belt Conveyor Products Handbook

103 Pages