Website:

FLEXCO

Website:

FLEXCO

Catalog excerpts

Pocket Instruction Guide Flexco® SR™ Rivet Hinged™ Fastening System

Open the catalog to page 1

Safety Checklist Proper Flexco* SR™ Selection Guidelines Proper Belt Preparation 7-11 Hammer Installation Power Installation Power Source: Powder Actuation Hilti DX 460-SR Powder Actuated Tool 32 Power Source: Electric Flexco* Electric Powered Rivet Driver 40 Power Source: Pneumatic Air Powered Rivet Driver 49

Open the catalog to page 2

Safety Checklist Serious personal injury may result by failure to comply with the following: Prior to any work on your conveyors, make certain that the power has been - turned off and the belt is locked out. ^=^= Follow other safety precautions outlined ^ Be sure to wear all recommended safety JSf equipment prior to engaging in any belt ^jy\J maintenance procedure.

Open the catalog to page 3

Proper Flexco® SR™ Selection Guidelines Proper Selection for the Flexco® SR™ Rivet Hinged Fastening System Flexco® SR Rivet Splice = Fastener Strip + Rivet + Pin + Installation Tool 1. Determine Belt Tension. Most conveyor belting has a mechanical fastener rating. Care should be taken not to operate the belting or fasteners beyond their recommended ratings. 2. Measure Belt Thickness. Choose a fastener size which corresponds to belt thickness. If fasteners are to be countersunk, measure the belt thickness after skiving.

Open the catalog to page 4

Proper Flexco® SR™ Selection Guidelines 3. Measure the Diameter of the Smallest Pulley in your Drive. For tail or take-up of the self-cleaning “wing type” pulley, 25% larger diameter dimensions are usually required. Only consider pulleys over which the belt makes at least a 90 degree wrap. Selection 4. Choose the Fastener Size that is Appropriate for your Specification. Flexco® Rivet Hinged Fastener Selection Chart Recommended Min. Pulley Diameter Fastener Size For Belts With Mechanical Fastener Ratings Up To: Belt Thickness Range

Open the catalog to page 5

Proper Flexco® SR™ Selection Guidelines 5. Select Material. Choose the metal characteristics which best suit your application. Not all sizes are available in all metals. Fastener Metals Fastener Abrasion Chemical Rust Spark- Available Material Resistance Resistance Resistance Magnetic Free Sizes Galvanized Steel 300 Series Stainless Steel Good to Excellent Excellent MegAlloy® Excellent 6. Select Installation Method. Flexco® SR fasteners can be hammer applied or choose a power installation option to speed installation time.

Open the catalog to page 6

Proper Flexco® SR™ Selection Guidelines 7. Select Rivets. Rivet Selection Chart Belt Thickness Range in. R2 SRAA SRA SRB R5 SRA SRB SRC SRC/D R5½ & R6LP SRB SRC SRC/D SRD SRE SRF* SRG* R6 SRC/D SRD SRE SRF SRG R8 SRC/D SRD SRE SRF SRG R9 SRG SRH SRI SRJ** SRK** SRL** Rapid Loader™ Collated Rivet Color Code N/A Red White Blue Orange Rivet Size White Blue Orange Green Purple Yellow Black Orange Green Purple Yellow Black Orange Green Purple Yellow Black Black Grey Lt. Blue Brown Tan Teal * Applies to RAR6LP only. ** Use with 3/4” diameter hinge pin.

Open the catalog to page 7

Proper Flexco® SR™ Selection Guidelines 8. Select Hinge Pin. AC – Bare Armored Cable: Heavy-duty, longwearing pin popular in underground mining applications. Armor wrapping protects interior wires. ACS – Bare Armored Stainless Steel Cable: The same advantages as bare armored cable plus corrosion resistance. NAC – Nylon Covered Armored Cable: Combines a durable armored steel wrap with a nylon covering for smooth operation and long service life. Nylon covering helps reduce pin migration and prolong pin life. Not recommended in wet, abrasive applications. NC – Nylon Covered Steel Cable: Nylon...

Open the catalog to page 8

Belt Preparation Proper Belt Preparation Improve workplace safety and maximize belt conveyor performance by following proper belt preparation practices. BELT LIFTING A Safer Way to Lift a Belt Lifting a conveyor belt out of the way to do belt repair and maintenance can be a difficult and hazardous job. To optimize worker safety when replacing worn idler rollers or to lift and flatten belt for a splicing station, avoid pry bars and manual lifting with a Flex-Lifter™ Belt Lifter. • Highest safe lift rating available: 4,000 lbs. (1810 kg) • Can safely lift a tensioned belt up to the stated...

Open the catalog to page 9

Belt Preparation BELT CLAMPING A Safer Way to Secure a Belt Avoid the problems and potential dangers associated with homemade devices such as c-clamps or lumber and chains. The Far-Pul® HD® Belt Clamp is specially designed to properly secure a belt and clamp it for safe belt conveyor maintenance. Belt Preparation • Built-in safety features allow a secure belt grip up to 1 inch (25 mm) thick • Provides even clamping tension across entire belt width • Load capacity up to 3 tons (2.7 metric tons) when used with two 1-1/2 ton (1/4 metric ton) come-a-longs

Open the catalog to page 10

Belt Preparation BELT SQUARING Accurate squaring of belt ends is essential to optimal positioning of the belt splice and provides for better fastener performance. Unevenly squared belts can lead to uneven belt tensions, belt mistracking, spillage issues, and ultimately to splice failure.

Open the catalog to page 11

Belt Preparation BELT CUTTING A Safer Way to Cut a Belt Belt Preparation Utility knives can’t provide the same level of safety, speed, and accuracy when cutting belts. And clean, square cut belt ends provide for optimal splice installation. To minimize the danger of accidental injury during the cutting process, choose a Flexco belt cutter. Electric Belt Cutter – Power assisted belt cutting for rubber belts up to 2” (50 mm) thick. 900 Series* Belt Cutter – Manually operated belt cutter for safe, accurate cuts up to 1-1/2” (38 mm) thick. *Patent pending

Open the catalog to page 12

Belt Preparation BELT SKIVING A Safer Way to Skive a Belt Whenever possible, Flexco recommends skiving the belt in order to countersink mechanical fasteners. Skiving reduces the fastener profile on the belt, resulting in improved fastener/cleaner compatibility and increased fastener service life. The FSK™ Belt Skiver safely removes top cover for installation of recessed splices. • Blade safely enclosed during skiving operations • Ideal for rubber-covered belts with top covers 3/16” (4.5 mm) thick or more Belt Preparation

Open the catalog to page 13All FLEXCO catalogs and technical brochures

-

DRX™ Dynamic Bed Series

2 Pages

-

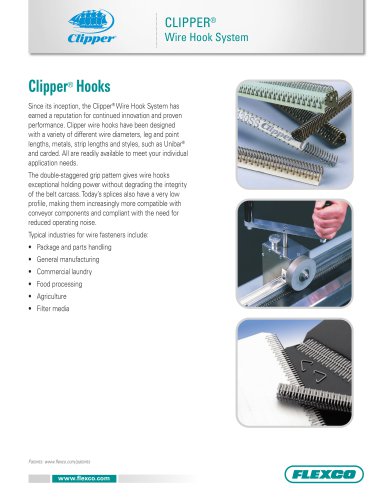

CLIPPER® Wire Hook System

12 Pages

-

CFC Secondary Cleaner

2 Pages

-

BELT-DRIVEN BRUSH CLEANER

2 Pages

-

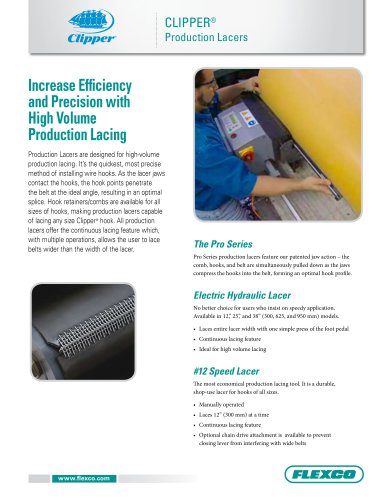

CLIPPER®

2 Pages

-

NOVITOOL®

2 Pages

-

SUPER-SCREW®

8 Pages

-

PT Smart™

2 Pages

-

TUG™ HD® Belt Clamps

2 Pages

-

Bolt Hinged Fastener System

4 Pages

-

MOTORIZED BRUSH CLEANER

2 Pages

-

Flexco SR Rivet Hinged

4 Pages

-

HV2 Precleaner with V-Tips

2 Pages

-

FGP Food Grade Precleaner

2 Pages

-

EZIB Flexco Impact Beds

2 Pages

-

electric belt cutter

2 Pages

-

DRX? 3000 Dynamic Beds

2 Pages

-

clipper® G Series Lacing

2 Pages

-

Chevron Belt Cleaner

2 Pages

-

Belt Conveyor Products Guide

24 Pages

-

BCP Overview

28 Pages

-

Belt Positioner Literature

2 Pages

-

MMP

2 Pages

-

H - Types

2 Pages

-

EZP-LS

2 Pages

-

Belt cleats

2 Pages

-

FSK Belt Skiver

2 Pages

-

SmartClamp? Belt Clamps

2 Pages

-

Far-Pul® HD® Belt Clamps

2 Pages

-

PT Smart? Tracking Insights

2 Pages

-

EZP1 Precleaner

2 Pages

-

Flexco Light Duty Products

8 Pages

-

CFMTS

9 Pages

Archived catalogs

-

2022 BELT CONVEYOR PRODUCTS

32 Pages

-

2015 BELT CONVEYOR PRODUCTS

17 Pages

-

X1642

4 Pages

-

X2088

2 Pages

-

X1893

2 Pages

-

X1207

2 Pages

-

Flexco Product Handbook

100 Pages

-

Belt Conveyor Products Handbook

103 Pages