Website:

FLEXCO

Website:

FLEXCO

Catalog excerpts

SMART SOLUTIONS FOR Belt conveyor OPERATIONS

Open the catalog to page 1

HELPING YOU MAXIMIZE As a world leader in belt conveyor solutions, Flexco understands the challenges facing belt conveyor systems, like those in hard rock mines, coal, and aggregate operations. That’s why we offer an extensive line of tough, durable belt conveyor products that increase uptime and output. Plus, we employ an experienced team who can help you make the right selections for your system. YOUR PRODUCTIVITY Increase Uptime Flexco manufactures a wide range of Mechanical Belt Fastening Systems to get your belts up and running fast — and keep them running — even in the most demanding...

Open the catalog to page 2

Enhance Safety Flexco® BR ™ Rivet Solid Plate Fasteners Features: • ulti-point rivet attachments pass between the M belt’s carcass fibers to ensure maximum grip • calloped Edge™ allows for increased S compatibility with belt cleaners and other conveyor components • For belts with mechanical fastener ratings from 400 to 800 P.I.W. (70 to 140 kN/m) and minimum pulley diameters from 14” – 36” (350 – 900 mm) • Available in a variety of metal types to best suit your application The Flexco Safe™ family of products makes each step in the belt conveyor maintenance process easier, faster, and safer....

Open the catalog to page 3

RE D U CE CARRY B AC K Mineline ® MHCP Heavy-Duty Cartridge Precleaner Easily remove material from the conveyor belt which can cause problems with other components on the conveyor. Features: • uick-change cartridge for easy Q blade replacement • uperShear™ segmented blades stand up to wet, S sticky material and abusive conditions Precleaners EZP1 Rockline ® Precleaner Features: • asy, visual check spring tensioning E • aceted ConShear™ blade — available in F standard urethane or high-temp options — renews its edge as it wears • imple, do-it-yourself installation S • Compatible with Flexco...

Open the catalog to page 4

Mineline ® MHS Secondary Cleaner with Service Advantage Cartridge™ Chevron Belt Cleaner Features: • egmented blades with choice of tungsten S carbide tips • atented PowerFlex™ cushions that maintain P optimal belt contact • ensioner and cushions create 4 points of relief, T making the cleaner fastener friendly • ervice advantage cartridge feature allows for S easy service and inspection • vailable in Stainless Steel A • lso available without cartridge feature A • leaner designed for chevron, cleated, and C raised-rib belts • undreds of rubber fingers create a rotary H cleaning action,...

Open the catalog to page 5

P r o t e c t t h e T a il Pull e y Eli m i n at e S p ill a g e Rocks, lumps, and other debris can get into the tail pulley and cause damage to the belt, splice, lagging, or pulley. Material spillage along the belt line means loss of production, clean-up time, and is a safety hazard for workers. Diagonal Plow Flex-Lok ™ Skirt Clamps Features: • ngled installation discharges material to a A designated side of the conveyor for easy cleanup • xclusive blade design “spirals” material quickly E off the belt • ong blade life with limited maintenance L Features: • nique, anti-vibration clamp pin...

Open the catalog to page 6

R e du c e Sli p p a g e PR O TECT THE B E L T Flexco makes it easy to find the pulley lagging you need to eliminate belt slippage, increase pulley life, improve water shedding, and boost productivity. Belt wear, belt damage, material degradation, or material rebound at the load point is common in high impact applications. DRX ™ Impact Beds Flex-Lag ® Ceramic Tile Lagging Features: Features: • uperior impact relief and maximum belt protection S • elocity Reduction Technology™ controls V acceleration to deaden impact energy and reduce reaction forces • nique Slide-Out Service™ feature gives...

Open the catalog to page 7

M a x i m iz e Y o u r O p e r at i o n ’ s P e r f o r m a n c e w i t h Fl e x c o Visit our website or contact your local distributor to learn more. 2525 Wisconsin Avenue • Downers Grove, IL 60515-4200 • USA Telephone: (630) 971-0150 • Fax: (630) 971-1180 • E-mail: info@flexco.com www.flexco.com Australia: 61-2-8818-2000 • Chile: 56-2-8967870 • China: 86-21-33528388 • England: 44-1274-600-942 • Germany: 49-7428-9406-0 India: 91-44-4354-2091 • Mexico: 52-55-5674-5326 • Singapore: 65-6281-7278 • South Africa: 27-11-608-4180 • USA: 1-630-971-0150 ©2012 Flexible Steel Lacing Company....

Open the catalog to page 8All FLEXCO catalogs and technical brochures

-

DRX™ Dynamic Bed Series

2 Pages

-

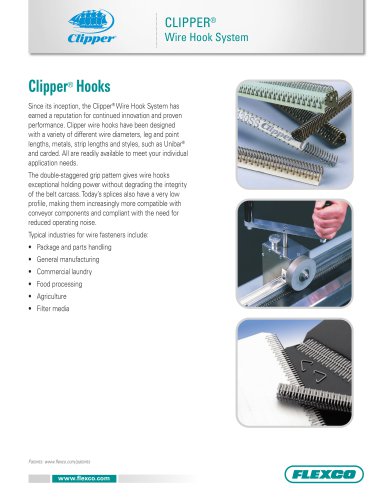

CLIPPER® Wire Hook System

12 Pages

-

CLIPPER® Production Lacers

2 Pages

-

CFC Secondary Cleaner

2 Pages

-

BELT-DRIVEN BRUSH CLEANER

2 Pages

-

CLIPPER®

2 Pages

-

NOVITOOL®

2 Pages

-

SUPER-SCREW®

8 Pages

-

PT Smart™

2 Pages

-

TUG™ HD® Belt Clamps

2 Pages

-

Bolt Hinged Fastener System

4 Pages

-

MOTORIZED BRUSH CLEANER

2 Pages

-

Flexco SR Rivet Hinged

4 Pages

-

HV2 Precleaner with V-Tips

2 Pages

-

FGP Food Grade Precleaner

2 Pages

-

EZIB Flexco Impact Beds

2 Pages

-

electric belt cutter

2 Pages

-

DRX? 3000 Dynamic Beds

2 Pages

-

Clipper® Production Lacers

2 Pages

-

clipper® G Series Lacing

2 Pages

-

Chevron Belt Cleaner

2 Pages

-

Belt Conveyor Products Guide

24 Pages

-

BCP Overview

28 Pages

-

Belt Positioner Literature

2 Pages

-

MMP

2 Pages

-

H - Types

2 Pages

-

EZP-LS

2 Pages

-

Belt cleats

2 Pages

-

FSK Belt Skiver

2 Pages

-

SmartClamp? Belt Clamps

2 Pages

-

Far-Pul® HD® Belt Clamps

2 Pages

-

PT Smart? Tracking Insights

2 Pages

-

EZP1 Precleaner

2 Pages

-

Flexco Light Duty Products

8 Pages

-

CFMTS

9 Pages

Archived catalogs

-

2022 BELT CONVEYOR PRODUCTS

32 Pages

-

2015 BELT CONVEYOR PRODUCTS

17 Pages

-

X1642

4 Pages

-

X2088

2 Pages

-

X1893

2 Pages

-

X1207

2 Pages

-

Flexco Product Handbook

100 Pages

-

Belt Conveyor Products Handbook

103 Pages