Website:

FLEXCO

Website:

FLEXCO

Catalog excerpts

Laundry Patch Fastener System Apply Fasteners and Patch in One Installation Process Gone are the days where binding laundry tapes and installing wire hooks were two different processes. With the Clipper® Laundry Patch Fastener System binding of the cotton laundry tapes and fastener installation is a single installation process. Clipper Wire Hooks are supplied preloaded into a patch material. The lacer applies pressure to the heated jaws to properly clinch the fasteners while simultaneously heating and activating the glue on the inside of the patch. The glue becomes liquid and permeates the laundry tape, and when cooled, binds the laundry tape fibers to prevent the fasteners from pulling through the belt end. Individual fasteners are secured in the patch material FPO Fastener points are covered by the patch during installation Custom patch logos available Heated jaws activate the glue during the quick installation process Built-in cooling station insures proper bonding of the patch material with the laundry tape Customer Value: • ne step process means no messy binder process and no fumes O to inhale F • ast installation and long-lasting splices ensure no lost production time • atch covering prevent hooks from catching and damaging linens P • From hours to seconds – the entire Clipper® patch process takes www.flexco.com www.flexco.com Laundry Patch Fastener and Pin Size Selection Chart Wire Diameter Belt Thickness Minimum Pulley Diameter

Open the catalog to page 1

Installation Tools Clipper® Laundry Patch Fasteners & Installation Tools Fasteners Patch Width Item Code Item Code Hooks Peer Strip The electric hydraulic PRO-150 offers the quickest and easiest methodology for installing the patch fasteners. Lacer includes both a heating/pressing station and a cooling station. PRO-150 Lacer and Hydraulic Pump (Does not include adapter) Power Supply 230 Volt; Single Phase; 60 Hz 230 Volt; Single Phase; 50 Hz 200 Volt; Three Phase; 50/60 Hz 230 Volt; Three Phase; 50/60 Hz 400 Volt; Three Phase; 50/60 Hz The PRO-120 offers a manual, yet quick, method for...

Open the catalog to page 2All FLEXCO catalogs and technical brochures

-

DRX™ Dynamic Bed Series

2 Pages

-

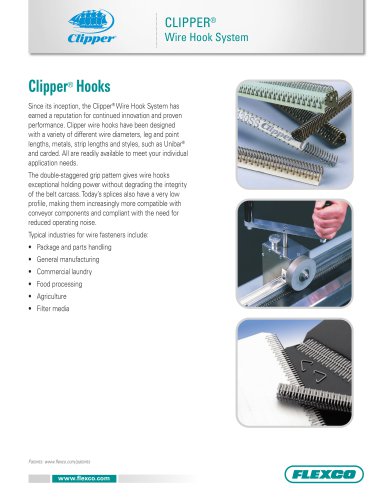

CLIPPER® Wire Hook System

12 Pages

-

CFC Secondary Cleaner

2 Pages

-

BELT-DRIVEN BRUSH CLEANER

2 Pages

-

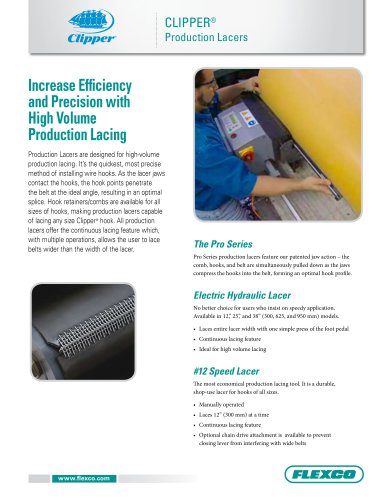

CLIPPER®

2 Pages

-

NOVITOOL®

2 Pages

-

SUPER-SCREW®

8 Pages

-

PT Smart™

2 Pages

-

TUG™ HD® Belt Clamps

2 Pages

-

Bolt Hinged Fastener System

4 Pages

-

MOTORIZED BRUSH CLEANER

2 Pages

-

Flexco SR Rivet Hinged

4 Pages

-

HV2 Precleaner with V-Tips

2 Pages

-

FGP Food Grade Precleaner

2 Pages

-

EZIB Flexco Impact Beds

2 Pages

-

electric belt cutter

2 Pages

-

DRX? 3000 Dynamic Beds

2 Pages

-

clipper® G Series Lacing

2 Pages

-

Chevron Belt Cleaner

2 Pages

-

Belt Conveyor Products Guide

24 Pages

-

BCP Overview

28 Pages

-

Belt Positioner Literature

2 Pages

-

MMP

2 Pages

-

H - Types

2 Pages

-

EZP-LS

2 Pages

-

Belt cleats

2 Pages

-

FSK Belt Skiver

2 Pages

-

SmartClamp? Belt Clamps

2 Pages

-

Far-Pul® HD® Belt Clamps

2 Pages

-

PT Smart? Tracking Insights

2 Pages

-

EZP1 Precleaner

2 Pages

-

Flexco Light Duty Products

8 Pages

-

CFMTS

9 Pages

Archived catalogs

-

2022 BELT CONVEYOR PRODUCTS

32 Pages

-

2015 BELT CONVEYOR PRODUCTS

17 Pages

-

X1642

4 Pages

-

X2088

2 Pages

-

X1893

2 Pages

-

X1207

2 Pages

-

Flexco Product Handbook

100 Pages

-

Belt Conveyor Products Handbook

103 Pages