Website:

FLEXCO

Website:

FLEXCO

Catalog excerpts

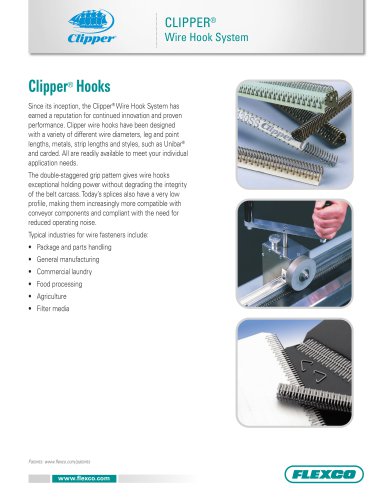

Flat, Low-Profile Splice Provides Strength and Durability Clipper® G Series™ Lacing is precision stamped from 316L stainless steel and then machine-applied for consistent compression, resulting in a uniform and flat splice. G Series lacing features a staggered-leg design with four alternating leg lengths. These varying points of belt penetration provide additional strength and durability for the finished splice. Ideal for use in food manufacturing, package and parts handling, and filter media, the Clipper G Series is designed for use with PVC, PU, and PES belting. Flat, Low-Profile splice is ideal for applications with slider beds Precision Stamping ensures a consistent 4.00 mm pitch over the entire length of the lacing for easier machine installation Machine-Application results in a uniform, flat splice – even on belts prone to belt wave Corrosion-Resistant stainless steel for demanding applications Features and Benefits: • asy to install with proven Clipper maintenance and production E lacers, G Series splices are uniform and extremely low profile. Th • e staggered legs on G Series lacing provide for varying points of belt penetration which increases both the strength and durability of the splice. • e flat, continuous top bar design eliminates belt wave Th and reduces the risk of dislodged fasteners. • Series lacing is joined with a corrugated stainless steel wire G connecting pin that prevents pin migration during use. www.flexco.com www.flexco.com Staggered Leg Geometry increases the strength and durability of the splice

Open the catalog to page 1

Clipper® G Series™ Lacing Recommended Applications: • Food Manufacturing • Filter Media • Package and Parts Handling G Series can be installed with: • Roller Lacer® • Roller Lacer® Gold Class™ • Microlacer® • Pro 600 Lacer • Pro 6000 Lacer G Series™ Fastener and Pin Size Selection Chart Minimum Pulley Diameter Material Thickness Ordering Information Ordering Number Clipper® maintenance lacers — quick, on-site installation of G Series™ lacing with precision Roller Lacing Technology™ Item Code G Series™ Face Strips and Combs Clipper® production lacers — the quickest, most precise method for...

Open the catalog to page 2All FLEXCO catalogs and technical brochures

-

DRX™ Dynamic Bed Series

2 Pages

-

CLIPPER® Wire Hook System

12 Pages

-

CLIPPER® Production Lacers

2 Pages

-

CFC Secondary Cleaner

2 Pages

-

BELT-DRIVEN BRUSH CLEANER

2 Pages

-

CLIPPER®

2 Pages

-

NOVITOOL®

2 Pages

-

SUPER-SCREW®

8 Pages

-

PT Smart™

2 Pages

-

TUG™ HD® Belt Clamps

2 Pages

-

Bolt Hinged Fastener System

4 Pages

-

MOTORIZED BRUSH CLEANER

2 Pages

-

Flexco SR Rivet Hinged

4 Pages

-

HV2 Precleaner with V-Tips

2 Pages

-

FGP Food Grade Precleaner

2 Pages

-

EZIB Flexco Impact Beds

2 Pages

-

electric belt cutter

2 Pages

-

DRX? 3000 Dynamic Beds

2 Pages

-

Clipper® Production Lacers

2 Pages

-

Chevron Belt Cleaner

2 Pages

-

Belt Conveyor Products Guide

24 Pages

-

BCP Overview

28 Pages

-

Belt Positioner Literature

2 Pages

-

MMP

2 Pages

-

H - Types

2 Pages

-

EZP-LS

2 Pages

-

Belt cleats

2 Pages

-

FSK Belt Skiver

2 Pages

-

SmartClamp? Belt Clamps

2 Pages

-

Far-Pul® HD® Belt Clamps

2 Pages

-

PT Smart? Tracking Insights

2 Pages

-

EZP1 Precleaner

2 Pages

-

Flexco Light Duty Products

8 Pages

-

CFMTS

9 Pages

Archived catalogs

-

2022 BELT CONVEYOR PRODUCTS

32 Pages

-

2015 BELT CONVEYOR PRODUCTS

17 Pages

-

X1642

4 Pages

-

X2088

2 Pages

-

X1893

2 Pages

-

X1207

2 Pages

-

Flexco Product Handbook

100 Pages

-

Belt Conveyor Products Handbook

103 Pages