Website:

FLEXCO

Website:

FLEXCO

Catalog excerpts

Keep your line

Open the catalog to page 1

SOLUTIONS FOR EVERY ISSUE ALONG THE BELT LINE With over 100 years of experience in the belt conveyor industry, Flexco knows that keeping your line running smoothly is essential to the success of your operation. That’s why we’ve developed a comprehensive line of innovative belt conveyor products that address the key issues you face. ACCESS DOOR Material that sticks to the belt after it leaves the transfer point and continues falling off along the conveyor’s return side. To address carryback, we offer: • Belt Cleaners • Belt Trainers • Belt Plows PRECLEANER (Polyurethane Blades) Belt drifts...

Open the catalog to page 2

Mineline – When “standard” products just won’t do. ® Flexco Mineline® products have been designed and engineered to work—day in and day out—in some of the toughest applications in the world. Regardless of the application, whether it be underground coal mining, port loading facilities, or other heavy tonnage applications that test the strength and durability of your conveyor system, Mineline is the answer. Customers have come to expect a Flexco cleaner, impact bed or tracker with the Mineline brand by its name to excel—even in situations where other products have failed. Next to Mineline...

Open the catalog to page 3

YOUR ISSUE: CARRYBACK OUR SOLUTION: ADVANCED CLEANING SYSTEMS Step 1 Understand Your Options BELT CLEANERS BLADE OPTIONS Precleaners • Mounted to the head pulley and below the material flow • Ideal for removing large pieces of material— typically about 60–70 percent of initial carryback • Blade width/material path options Polyurethane • Easier on the belt lices • Works well with mechanical splices • Economical • Specialty formulations for high heat, chemical resistance, or water removal Secondary cleaners • Located just past where the belt leaves the head pulley—and anywhere else down the...

Open the catalog to page 4

FLEXCO PRECLEANERS Standard-duty, solid-blade design rated up to 275° F (135° C) Can handle temperature spikes to 325° F (163° C) Visual tension check Requires just 4" (100 mm) of horizontal clearance Do-it-yourself installation and minimal maintenance EZP1 Stainless Steel Food Grade Precleaner • • • • Stainless steel components for superior corrosion resistance Standard-duty, solid-blade design Visual tension check White food-grade, chemical-resistant ConShear™ blade Maximum Belt Speed*: 700 fpm (3.5 m/sec) Maximum Belt Speed*: 700 fpm (3.5 m/sec) Applications: Fermentation Byproducts,...

Open the catalog to page 5

FLEXCO PRECLEANERS FLEXCO PRECLEANERS Optional HV Protected Tips MMP Medium Mine-Duty Precleaner Stainless Steel MMP Medium-Duty Precleaner • Medium-duty mining precleaner with TuffShear™ blade • Heavy-duty, 3-piece design pole with dual tensioners • Visual tension check • Stainless steel components for superior corrosion resistance • Medium-duty mining precleaner • Heavy-duty, 3-piece design, corrosion-resistant pole with dual tensioners • Visual tension check Maximum Belt Speed*: 1000 fpm (5.0 m/sec) Pulley Diameter from 16”–48” (400–1200 mm) • Tungsten carbide tip provides superior...

Open the catalog to page 6

FLEXCO SECONDARY CLEANERS P-Type® Secondary Cleaner P-Type® Cartridge Secondary Cleaner • Available with C-tips for mechanical fastener applications or V-tips for vulcanized applications • Segmented, tungsten carbide blades • Bolt-up tensioning system • Limited space model option for telescoping, stacking, or portable conveyors FLEXCO S E C ON DARY C L EA NERS FEATURES & APPLICATIONS • Available with C-tips for mechanical fastener applications or V-tips for vulcanized applications • Bolt-up tensioning system • Service Advantage Cartridge feature allows for easy service and inspection...

Open the catalog to page 7

FLEXCO SECONDARY CLEANERS Stainless Steel MHS Heavy-Duty Secondary Cleaner FLEXCO SECONDARY CLEANERS MHS Secondary Cleaner with Service Advantage Cartridge™ • Stainless steel components for extra corrosion resistance • Segmented blades with choices of tungsten carbide tips • Patented PowerFlex™ cushions maintain optimal belt contact • Tensioners and cushion create 4 points of relief, making the cleaner fastener-friendly • Segmented blades with choices of tungsten carbide tips • Patented PowerFlex™ cushions maintain optimal belt contact • Tensioners and cushion create 4 points of relief,...

Open the catalog to page 8

CONSHEAR™ STANDARD CONSHEAR™ HIGH TEMP CONSHEAR™ WHITE incl. 2 plates, 16" x 32" (400 x 800 mm) • For use with Mounting Bars to mount cleaners on open head pulleys • For use with MSP MMP MHP MHCP , , , incl. 8 bolts, nuts and washers • For mounting precleaners on open head pulleys • Weld on both sides of pulley and bolt on steel plates • For use with MSP MMP MHP MHCP , , , • Used with both Standard and Long SST Mounting Bracket Kits (below left) for additional mounting options Precleaner Options Application Description Temperature Range Reversing Belts Mechanical Fasteners Belt Width* Belt...

Open the catalog to page 9

YOUR ISSUE: BELT MISTRACKING OUR SOLUTION: BELT TRAINERS FLEXCO BELT TRAINERS • Sensor rollers detect wander, then “pivot and tilt” belt into place • Economical solution for medium-tension belts • Effectively prevents belt from damaging structure • Easy to install • Specially designed to fit underground conveyors To select the right belt trainer, you need to consider whether: • The belt is wandering to one or both sides • The top or return side of the belt is affected • The mistracking is happening consistently or occasionally Maximum Belt Tension: 1600 PIW • The belt has a low, medium, or...

Open the catalog to page 10

When it comes to load zones, our impact beds deliver the highest level of material containment and belt protection. They’ve been specially designed to control acceleration, deaden impact energy, reduce damaging vibrations, and extend belt life. YOUR ISSUE: LOAD-POINT SPILLAGE OUR SOLUTION: IMPACT BEDS, SLIDER BEDS, SKIRTING SYSTEMS, PLOWS & MORE Set Up an Appropriate Transition Distance • Often compromised to save space, but short transition can lead to premature belt, lagging, and idler wear or failure. • Using your idlers or Flexco adjustable idlers, follow CEMA recommendations based on...

Open the catalog to page 11All FLEXCO catalogs and technical brochures

-

DRX™ Dynamic Bed Series

2 Pages

-

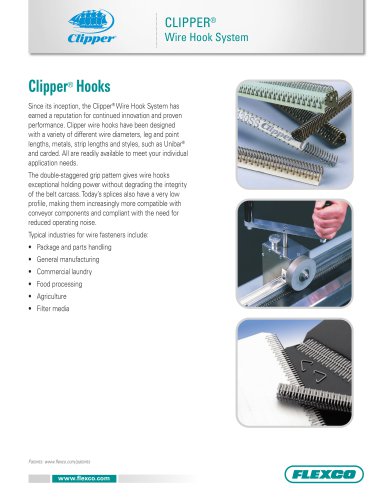

CLIPPER® Wire Hook System

12 Pages

-

CLIPPER® Production Lacers

2 Pages

-

CFC Secondary Cleaner

2 Pages

-

BELT-DRIVEN BRUSH CLEANER

2 Pages

-

CLIPPER®

2 Pages

-

NOVITOOL®

2 Pages

-

SUPER-SCREW®

8 Pages

-

PT Smart™

2 Pages

-

TUG™ HD® Belt Clamps

2 Pages

-

Bolt Hinged Fastener System

4 Pages

-

MOTORIZED BRUSH CLEANER

2 Pages

-

Flexco SR Rivet Hinged

4 Pages

-

HV2 Precleaner with V-Tips

2 Pages

-

FGP Food Grade Precleaner

2 Pages

-

EZIB Flexco Impact Beds

2 Pages

-

electric belt cutter

2 Pages

-

DRX? 3000 Dynamic Beds

2 Pages

-

Clipper® Production Lacers

2 Pages

-

clipper® G Series Lacing

2 Pages

-

Chevron Belt Cleaner

2 Pages

-

Belt Conveyor Products Guide

24 Pages

-

BCP Overview

28 Pages

-

Belt Positioner Literature

2 Pages

-

MMP

2 Pages

-

H - Types

2 Pages

-

EZP-LS

2 Pages

-

Belt cleats

2 Pages

-

FSK Belt Skiver

2 Pages

-

SmartClamp? Belt Clamps

2 Pages

-

Far-Pul® HD® Belt Clamps

2 Pages

-

PT Smart? Tracking Insights

2 Pages

-

EZP1 Precleaner

2 Pages

-

Flexco Light Duty Products

8 Pages

-

CFMTS

9 Pages

Archived catalogs

-

2022 BELT CONVEYOR PRODUCTS

32 Pages

-

X1642

4 Pages

-

X2088

2 Pages

-

X1893

2 Pages

-

X1207

2 Pages

-

Flexco Product Handbook

100 Pages

-

Belt Conveyor Products Handbook

103 Pages