Website:

FLEXCO

Website:

FLEXCO

Catalog excerpts

Tungsten Carbide Blades #1002 Are all tungsten carbide blades the same? • Absolutely not! Carbide is a composite of carbide granules and binder metals that provides a very hard, long-wearing material for belt cleaner blades. There are several ways to vary the mixture. • Some low cost carbides can have inferior wear resistance which results in short blade life. Others have poor impact resistance and can chip out—potentially causing damage to the belt. • Many blade tips are weakened with voids or binder pooling due to inferior production processes. Bargain-priced carbide isn’t always a bargain. Why choose a tungsten carbide blade. Look for blades that offer: • Better cleaning efficiency. When optimally tensioned, the thin, hard blade will provide superior cleaning performance. • Good value. When you consider lifetime cost vs. initial cost, a tungsten carbide blade’s durability and lower required maintenance often makes up the cost difference over the life of the blade. • Versatility. Some designs can be used with mechanical belt fasteners. (See back page for reference information.) Poor quality carbides may have the defects shown. Where to use tungsten carbide blades. • Highest cleaning efficiency is another attribute that makes tungsten carbide the right choice in applications where unbeatable performance is required. • Highly abrasive materials are commonly conveyed on belts that use these wear-resistant blades. • Reduced maintenance is the reason why many users choose carbide-tipped blades; they’re well worth the investment in applications where less durable blade materials result in unacceptable wear rates, cause frequent retensioning tasks and increase maintenance costs. Why are tungsten carbide blades used on belt cleaners? Tungsten carbide tipped blades provide superior cleaning efficiency. They also feature a lower lifetime cost—due to their durability—compared to many other blade types. Traditionally, tungsten carbide blades have been compatible only with vulcanized belts. Today, technical advancements with certain blade options make these blades more compatible with mechanically spliced belts as well. Binder pooling Voids in structure Grade contamination Coarse structure Poor quality carbide that wears unevenly, with high points. Belt Cleaners

Open the catalog to page 1

Tungsten Carbide Blades High grade carbide blades are worth the investment. Flexco’s tungsten carbide blades are made from a superior grade of carbide – free from contamination, binder pooling, voids and coarse structure that often occur in inferior products. This superior composite makes our carbide blades long lasting and impact resistant. Flexco has done extensive research and invested years of testing to design and manufacture the right tungsten carbide blades for demanding applications. A carefully selected standardized ASTM Abrasion Test (results shown at right) shows Flexco’s carbide...

Open the catalog to page 2All FLEXCO catalogs and technical brochures

-

DRX™ Dynamic Bed Series

2 Pages

-

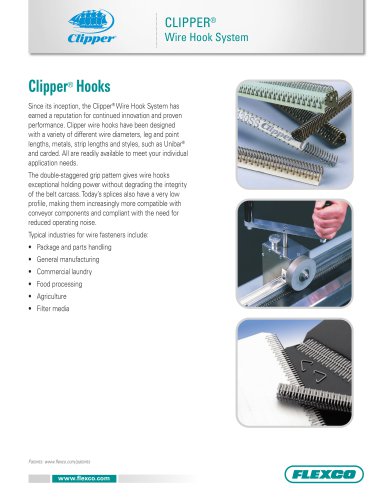

CLIPPER® Wire Hook System

12 Pages

-

CLIPPER® Production Lacers

2 Pages

-

CFC Secondary Cleaner

2 Pages

-

BELT-DRIVEN BRUSH CLEANER

2 Pages

-

CLIPPER®

2 Pages

-

NOVITOOL®

2 Pages

-

SUPER-SCREW®

8 Pages

-

PT Smart™

2 Pages

-

TUG™ HD® Belt Clamps

2 Pages

-

Bolt Hinged Fastener System

4 Pages

-

MOTORIZED BRUSH CLEANER

2 Pages

-

Flexco SR Rivet Hinged

4 Pages

-

HV2 Precleaner with V-Tips

2 Pages

-

FGP Food Grade Precleaner

2 Pages

-

EZIB Flexco Impact Beds

2 Pages

-

electric belt cutter

2 Pages

-

DRX? 3000 Dynamic Beds

2 Pages

-

Clipper® Production Lacers

2 Pages

-

clipper® G Series Lacing

2 Pages

-

Chevron Belt Cleaner

2 Pages

-

Belt Conveyor Products Guide

24 Pages

-

BCP Overview

28 Pages

-

Belt Positioner Literature

2 Pages

-

MMP

2 Pages

-

H - Types

2 Pages

-

EZP-LS

2 Pages

-

Belt cleats

2 Pages

-

FSK Belt Skiver

2 Pages

-

SmartClamp? Belt Clamps

2 Pages

-

Far-Pul® HD® Belt Clamps

2 Pages

-

PT Smart? Tracking Insights

2 Pages

-

EZP1 Precleaner

2 Pages

-

Flexco Light Duty Products

8 Pages

-

CFMTS

9 Pages

Archived catalogs

-

2022 BELT CONVEYOR PRODUCTS

32 Pages

-

2015 BELT CONVEYOR PRODUCTS

17 Pages

-

X1642

4 Pages

-

X2088

2 Pages

-

X1893

2 Pages

-

X1207

2 Pages

-

Flexco Product Handbook

100 Pages

-

Belt Conveyor Products Handbook

103 Pages