Website:

FLEXCO

Website:

FLEXCO

Catalog excerpts

Project Profile 1-On-2 Feeding PRB Coal to Two Crushers Industry Powder River Basin Coal Mining Application Run of mine coal is fed to two large roll crushers via a transfer chute that provides an accurate and controllable split of the proportion of coal flow fed to each crusher. Material Powder River Basin Coal Objective • Provide a system capable of delivering an accurate and controllable split of material flow • Deliver coal to each crusher by evenly spreading across the full feed width of each crusher Transfer Detail Feed belt is a 72” wide 8,000 tph system feeding two roll crushers. Challenge The mine needed a system capable of controlling flow to their two large roll crushers, which are the life line for feeding the mine’s rail car loading operations. In addition to being capable of feeding either crusher individually and providing a controllable split of the material to both crushers, the system had to provide an even feed of material across the full feed width of each crusher. Tasman Warajay Solution Flexco designed and fabricated a 1-on-2 transfer chute with Tasman Warajay Technology™ which included removable chrome carbide overlay wear liners. The system features Flexco’s proprietary bucket diverter technology coupled with a spreader section in front of each crusher. Result The new Flexco transfer chute provides the operational flexibility this high-productivity mine requires. The mine is now able to control the split of material to both crushers. The chutes also allow the material to be evenly distributed to the crusher, preventing uneven wear of the rollers. 401 Remington Boulevard, Suite A • Bolingbrook, IL 60440 U.S.A. Tel: 1-815-609-7025 • Fax: 1-815-609-0566 ©2012 Flexible Steel Lacing Company. 03-12. For PDF: W057 www.flexco.com www.flexco.com

Open the catalog to page 1All FLEXCO catalogs and technical brochures

-

DRX™ Dynamic Bed Series

2 Pages

-

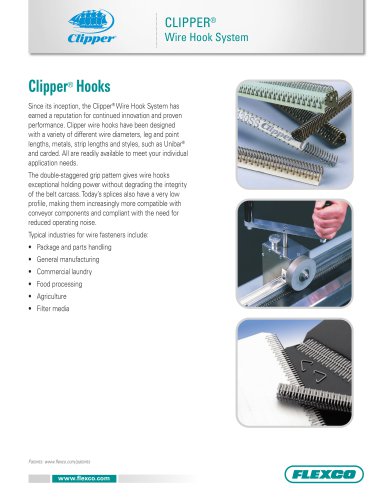

CLIPPER® Wire Hook System

12 Pages

-

CLIPPER® Production Lacers

2 Pages

-

CFC Secondary Cleaner

2 Pages

-

BELT-DRIVEN BRUSH CLEANER

2 Pages

-

CLIPPER®

2 Pages

-

NOVITOOL®

2 Pages

-

SUPER-SCREW®

8 Pages

-

PT Smart™

2 Pages

-

TUG™ HD® Belt Clamps

2 Pages

-

Bolt Hinged Fastener System

4 Pages

-

MOTORIZED BRUSH CLEANER

2 Pages

-

Flexco SR Rivet Hinged

4 Pages

-

HV2 Precleaner with V-Tips

2 Pages

-

FGP Food Grade Precleaner

2 Pages

-

EZIB Flexco Impact Beds

2 Pages

-

electric belt cutter

2 Pages

-

DRX? 3000 Dynamic Beds

2 Pages

-

Clipper® Production Lacers

2 Pages

-

clipper® G Series Lacing

2 Pages

-

Chevron Belt Cleaner

2 Pages

-

Belt Conveyor Products Guide

24 Pages

-

BCP Overview

28 Pages

-

Belt Positioner Literature

2 Pages

-

MMP

2 Pages

-

H - Types

2 Pages

-

EZP-LS

2 Pages

-

Belt cleats

2 Pages

-

FSK Belt Skiver

2 Pages

-

SmartClamp? Belt Clamps

2 Pages

-

Far-Pul® HD® Belt Clamps

2 Pages

-

PT Smart? Tracking Insights

2 Pages

-

EZP1 Precleaner

2 Pages

-

Flexco Light Duty Products

8 Pages

-

CFMTS

9 Pages

Archived catalogs

-

2022 BELT CONVEYOR PRODUCTS

32 Pages

-

2015 BELT CONVEYOR PRODUCTS

17 Pages

-

X1642

4 Pages

-

X2088

2 Pages

-

X1893

2 Pages

-

X1207

2 Pages

-

Flexco Product Handbook

100 Pages

-

Belt Conveyor Products Handbook

103 Pages